I recently acquired a Stihl 028av Super that I want to get back into proper working order. I dont have any gas so I honestly dont even know if it runs. I checked the spark and its nice and bright and their seems to be plenty of compression by using the "its hard to pull the cord" , and its "easy to pull with the plug out" technique.

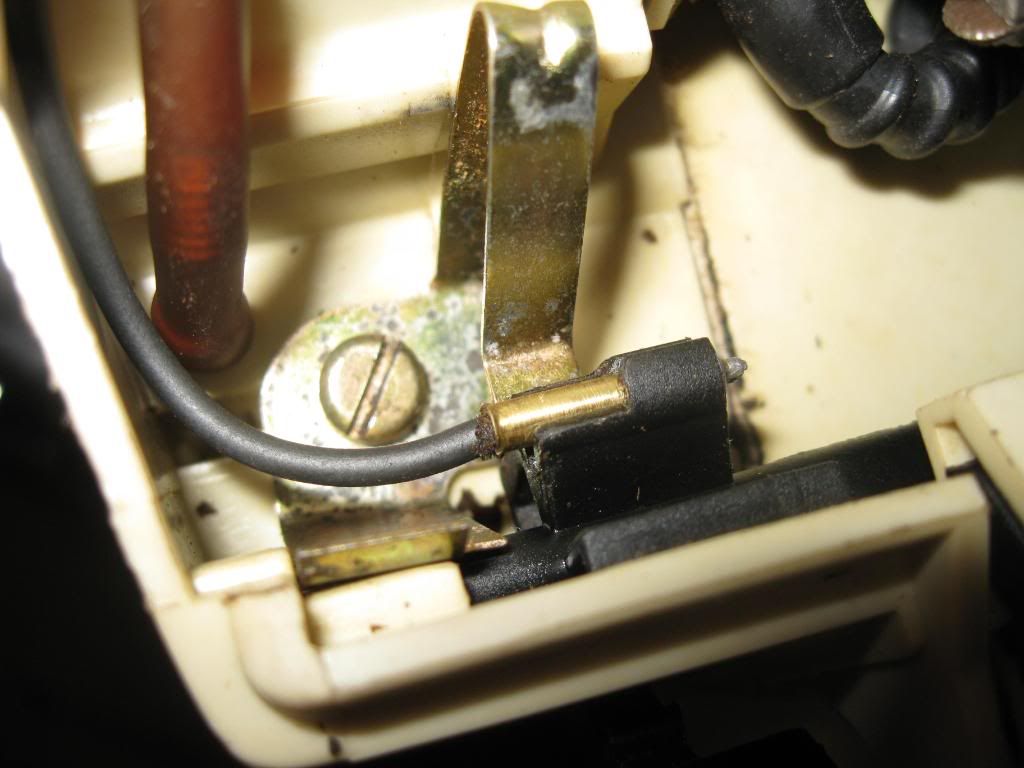

My first question is that when you grab the top handle, and move the bar up and down the engine casing floats around as if on a pivot. Is it broken?

I dont even know enough to be able to name the parts I am asking about, but the top handle that loops around to the two bottom screws onto the plastic body if you are holding it in both hands and put downward pressure on the chain bar as if you are cutting, it flexes about 2 inches.

Second, Are these saws worth dumping any money into? I hear 028's are reliable for occasional use (Im really looking for a post hurricane every now and then type of saw that is RELIABLE) ?

I'll try and get some pictures up if I'm not making any sense about the handle flexing.

Thanks!

My first question is that when you grab the top handle, and move the bar up and down the engine casing floats around as if on a pivot. Is it broken?

I dont even know enough to be able to name the parts I am asking about, but the top handle that loops around to the two bottom screws onto the plastic body if you are holding it in both hands and put downward pressure on the chain bar as if you are cutting, it flexes about 2 inches.

Second, Are these saws worth dumping any money into? I hear 028's are reliable for occasional use (Im really looking for a post hurricane every now and then type of saw that is RELIABLE) ?

I'll try and get some pictures up if I'm not making any sense about the handle flexing.

Thanks!