OK now, if the ball busting is over and done with...

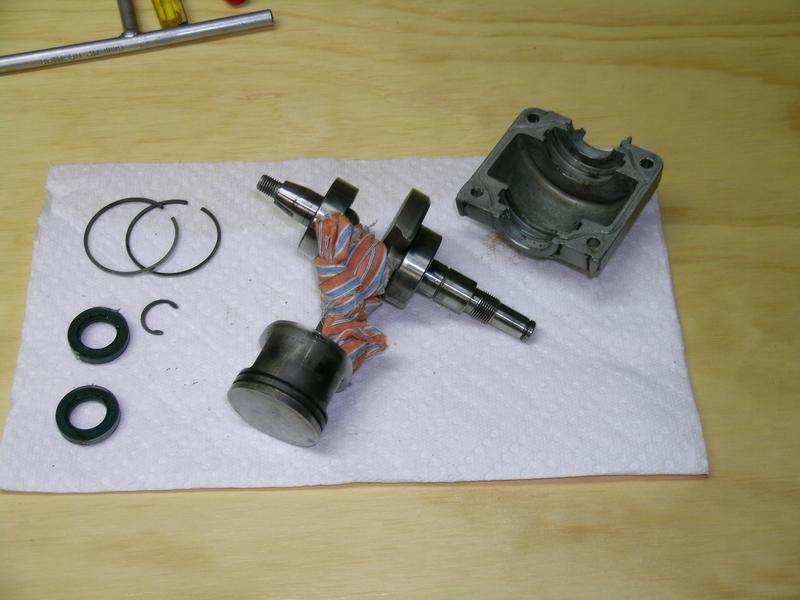

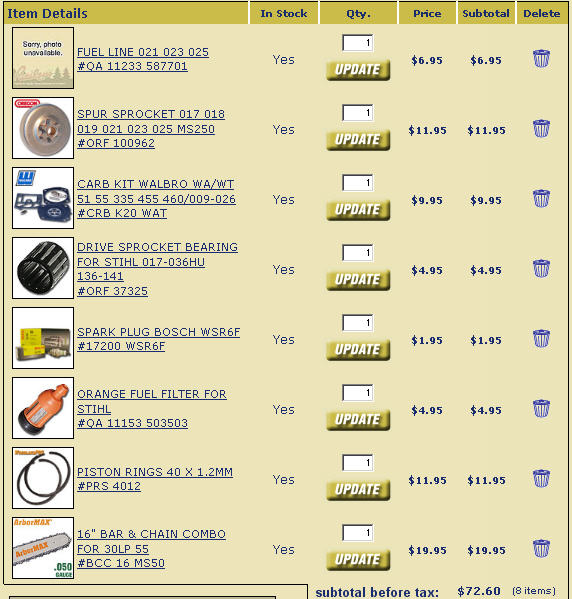

The piston rings come qty 2 to a kit. So no extra there.

The seals, cheap ones at least, are eluding me right now. Ordinarily they are a couple of bucks at NAPA, but they are

priced higher now ($6.99 ea) for whatever reason.

The impulse line I may have to buy from the dealer near where I work, since I can't seem to find one online.

The carb kit is OEM Walbro.

The ArborMax B&C setup didn't come to me out of thin air; a quick search will turn up a number of satisfied AS'ers. It's an occasional use firewood saw; I'm not staring in a TV show with it.

Shipping for this lot to my zip code is $9.82.

I'm believe still under my previously discussed $100 allotted budget. So...

Or give me an idea of something else to do. I haven't ordered anything yet, I wanted to get done with cleaning it up so I didn't have to place a 2nd order for something small.

Jim / Wrooster