Eccentric

Mister Wizard

I like that one better. I'm game.

Next question is when?

Last edited:

Looking at two weeks.

I have a small bit of business near there, something to finish at the old homestead.

I have a small bit of business near there, something to finish at the old homestead.

I just happened into a Model 17 with stuck motor. Had piston freed and compression, but no spark within 20 minutes. A little white death on the bottom of the handle, but inside of the gas tank looks clean. more to report as progress is made. If anyone is familiar with these, I'd appreciate any input.

Thanks,

Jim in the Wood.

PS: Pictures to come later on the Model 17. it's rough, but saveable. We are used to corrosion and rust in New England.

I have a small bit of business near there, something to finish at the old homestead.

650s run well enough. The Pissfirs decided to replace their 1020s with 650s. The 650s came with 36" bars and 3/8" chain, the 1020s ran .404 on 42" bars. There were several times that missing 6" in bar length was missed.

After a month or so, we got the 1020s back, almost all of the 650s were in the shop with fractures in the cases, they proved to be too fragile for that type of service. In contrast, the 1020s just had a lot of paint loss.

just trying to mix it up on the colors. i've got my eye on a 990d and 990g. i'll see if the luck with the yellow will spill over to some red.650s run well enough. The Pissfirs decided to replace their 1020s with 650s. The 650s came with 36" bars and 3/8" chain, the 1020s ran .404 on 42" bars. There were several times that missing 6" in bar length was missed.

After a month or so, we got the 1020s back, almost all of the 650s were in the shop with fractures in the cases, they proved to be too fragile for that type of service. In contrast, the 1020s just had a lot of paint loss.

My first $15 evilbay C5 and now this one I pulled from a pile have 125 psi.

Is that a normal reading on one in good condition or can there be more to be had. I.E. New rings and leave out the base gasket.

Carl.

Important business my friend.

Got that Homelite 750 back together and running. Came in for dinner, and am about to go back out and square away a few remaining details (stripped flywheel cover bolt, starter rope replacement). Man that saw's a beast. Haven't been around a good running 750 for a few years. You don't see many old magnesium 6.8ci saws that'll spin up to 12K RPM's RIGHT NOW. Sent a chill up my spine when it lit off this afternoon.

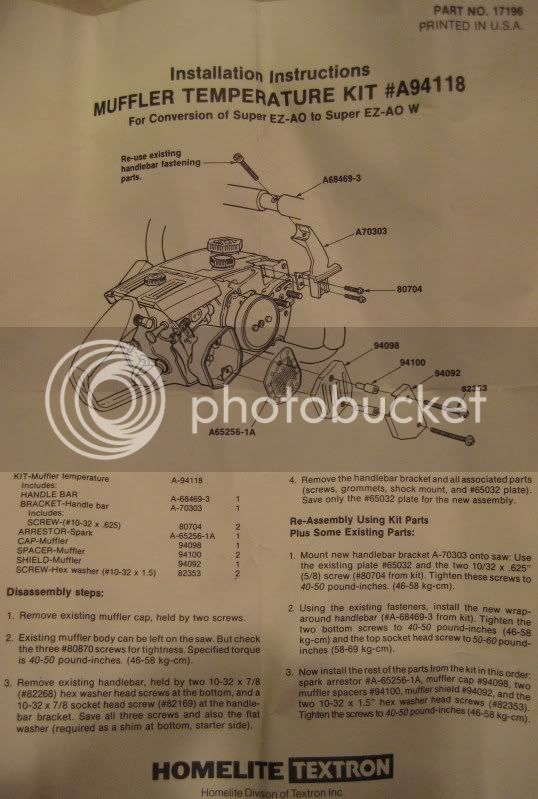

I picked up this NOS Western kit for a Super EZ. I've seen a couple EZ's with a full wrap before, but this is the first kit I've come across. I thought I'd share the info.

They didn't have much more than that when new. Fresh rings and substituting Threebond or Motoseal for the base gasket will bring it up a scosh. Never gonna be a hot rod. You can wake it up a bit by putting a C9/91/XP-Series intake manifold and four petal pyramid reed setup on it.

if you tap on the threaded end of crank - BE SURE to put the flywheel retaining nut on first, run it on until it is even with the end of the crank, then "tap".

the nut does two things for you:

1. it keeps you from buggering up the end of the crank and threads

2. it keeps the flywheel from falling off and hitting the floor.

btw, tippy tapping never helps me. i use a 3# hammer and tap it with authority. never fails. just don't go nuclear on it. remember that the shock you impart to the crank is transmitted to the rest of the saw.

Enter your email address to join: