You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Building another hotrod MS661C

- Thread starter blsnelling

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

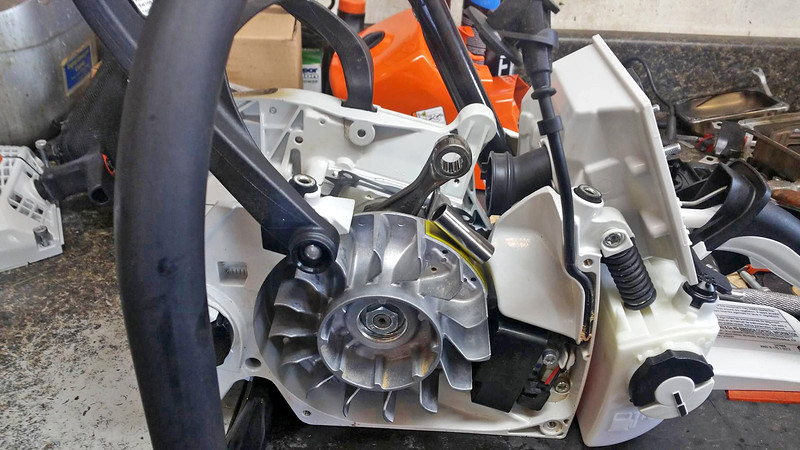

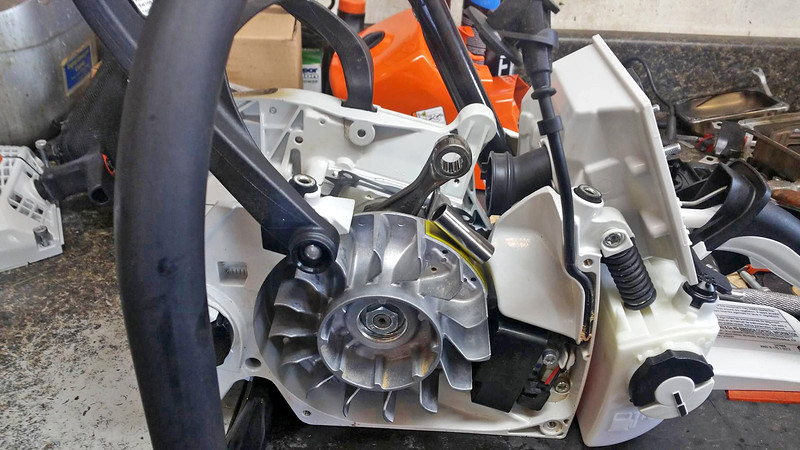

Here is the saw bone stock. It only made one cut before this video was shot. They run mighty nice for a stock saw.

Pulling the flywheel.

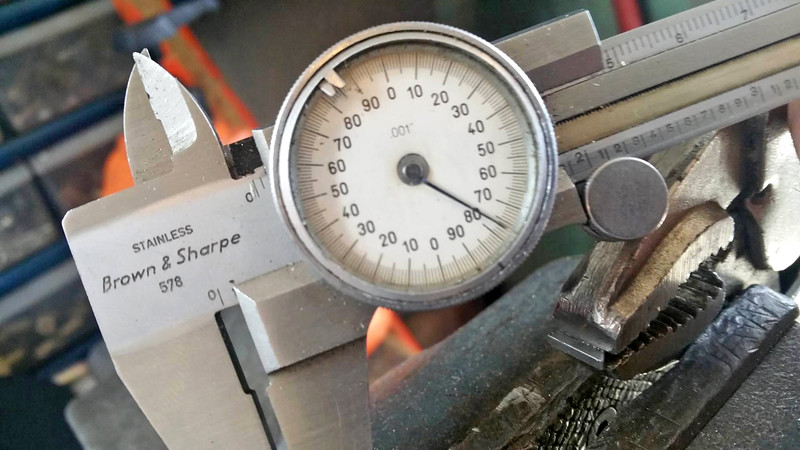

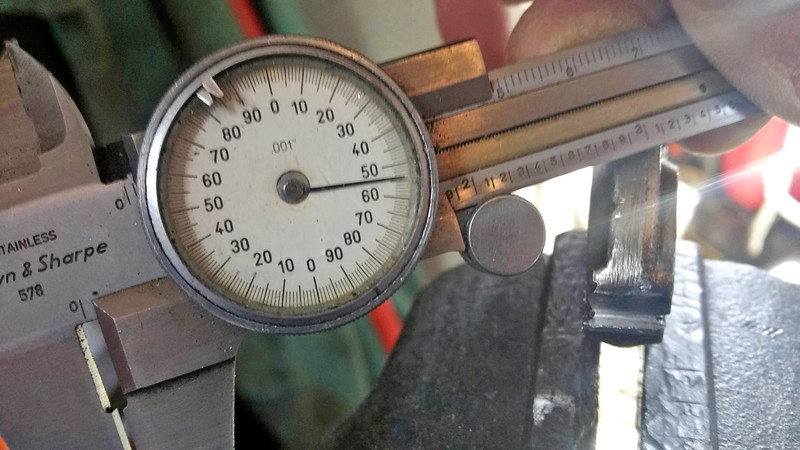

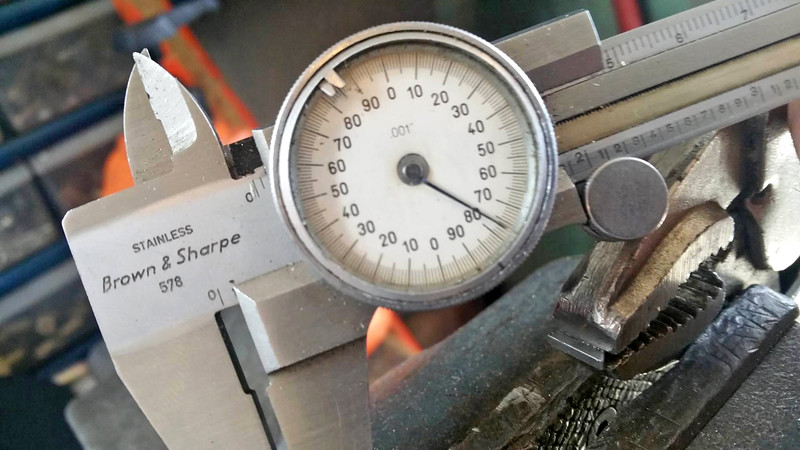

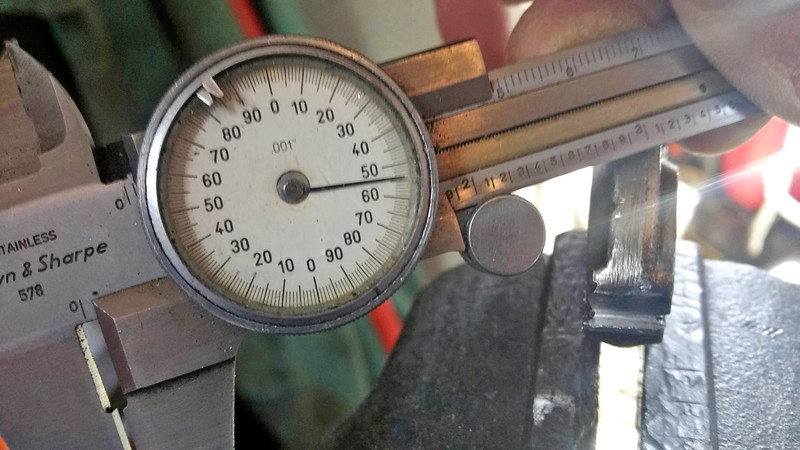

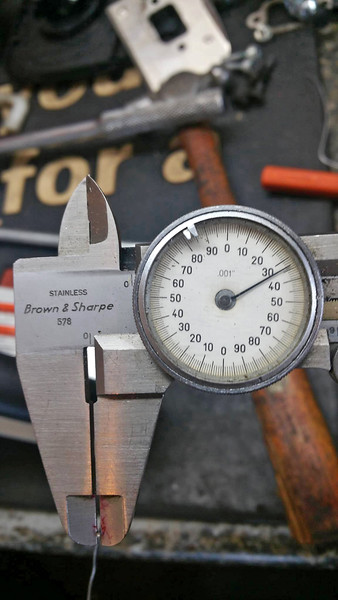

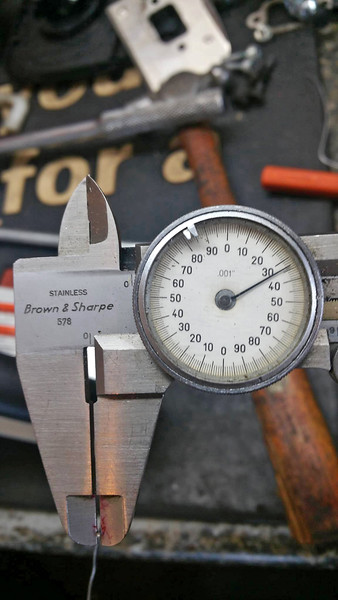

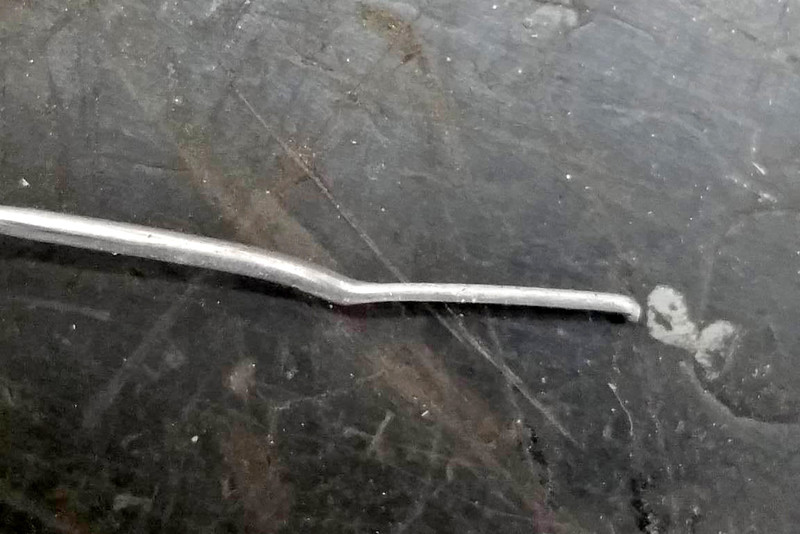

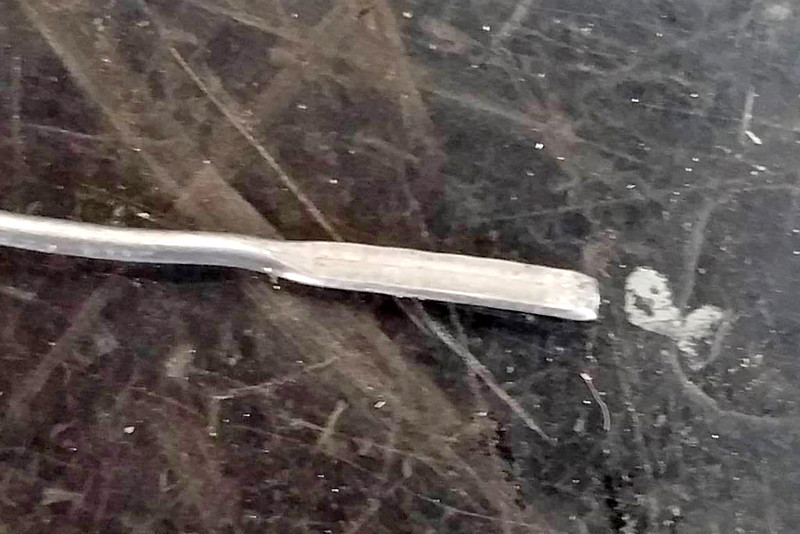

The key is a little over .075" thick.

I file down the portion that sticks out of the crank so that the flywheel can be indexed CCW in order to advance the ignition timing.

The key is a little over .075" thick.

I file down the portion that sticks out of the crank so that the flywheel can be indexed CCW in order to advance the ignition timing.

Squish from the factory was .033"-.034".

Once I know the squish, the cylinder comes off and I can do the machine work.

I just touch the bottom of the piston skirts in order to make sure they're square with the crown.

I then turn a popup on the piston crown. I give the edge of the popup a 45° angle.

Once I know the squish, the cylinder comes off and I can do the machine work.

I just touch the bottom of the piston skirts in order to make sure they're square with the crown.

I then turn a popup on the piston crown. I give the edge of the popup a 45° angle.

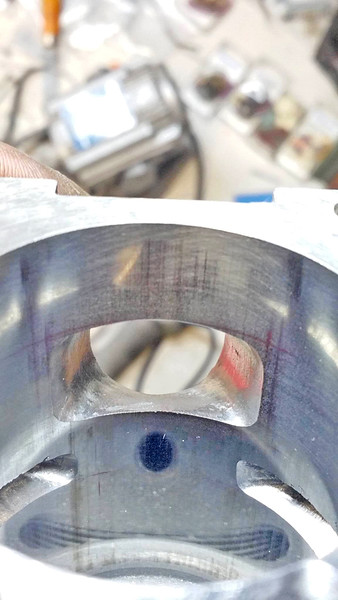

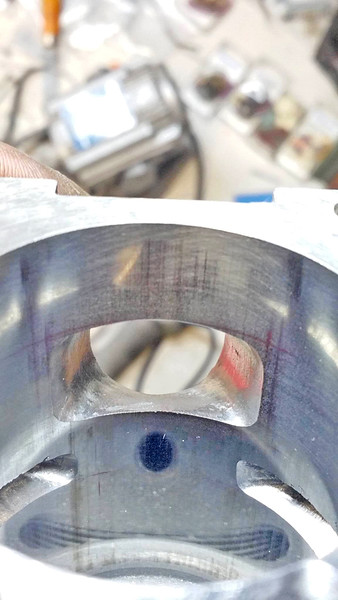

This is just one of the rough cuts on both the piston and cylinder.

Here you can see where I did a little porting on the transfer intake duct.

Squish after machining was a strong .020", right where I wanted it.

I check the squish on all 4 corners. This is partly to make sure the popup isn't too close to the edge of the combustion chamber.

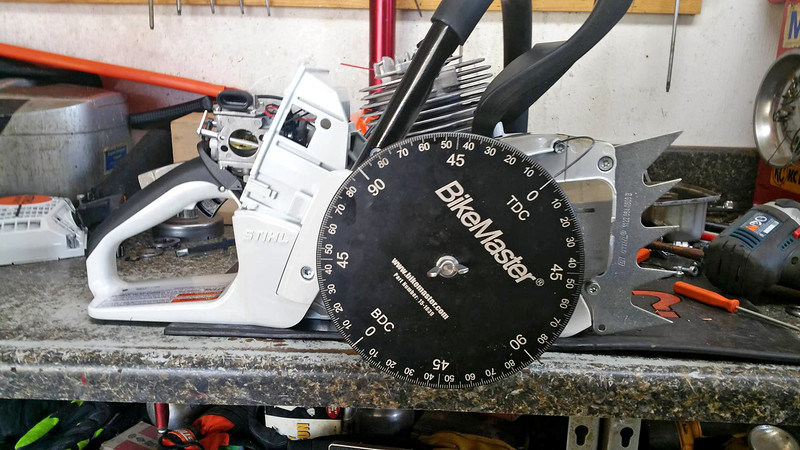

Setting up the degree wheel.

I've found through testing that completely removing the baffler is the best way to go.

I will cut a new screen with more open space in it. If this weren't a daily work saw I'd also add gills to both sides of the muffler cover. In this case, I'd rather keep the volume down a little.

That's it for now. More to come later.

- Joined

- Apr 28, 2014

- Messages

- 7,785

- Reaction score

- 10,433

I once thought that if I ever need some custom work done on a saw, I'd just do it myself. Hell, I have a dremel tool.

Now, I'm going to send it to you.

Now, I'm going to send it to you.

Chainsaw Jim

CJ Saws, LLC

Lookin good. I can't wait to see the after video.

Whitty21

ArboristSite Operative

One of my life goals is to completely tear into a NIB saw

My photo editing software does some weird stuff to cylinder pictures. Please ignore the "dark marks".

Woos31

Addicted to ArboristSite

As always great work B-rad and thanks for sharing the photos and explanation

zogger

Tree Freak

Lathes sure are handy...

She's done and runs fantastic.

I only remove the casting lines here.

All done and back together.

I only remove the casting lines here.

All done and back together.

banana boat

ArboristSite Operative

Wheres the after vid?

It's uploading now.Wheres the after vid?

banana boat

ArboristSite Operative

Sweet

KiwiBro

Mill 'em, nails be damned.

What guarantee is there this one won't suffer faults (not of your making I should point out) as the other one did? Especially in light of the OEM warranty being voided by the modifications?

I thought I was going to have to wait until Monday to make the after mods video, but my sweet wife held the flashlight so that I could make a video at 9:30 at night

Similar threads

- Replies

- 10

- Views

- 837

- Replies

- 8

- Views

- 2K