southland1

ArboristSite Member

OK on the chain break piece, will see where it fits. The plastic piece is identical size on both sides. Seems to be where you can use the saw vented or unvented. Maybe for different types of weather.

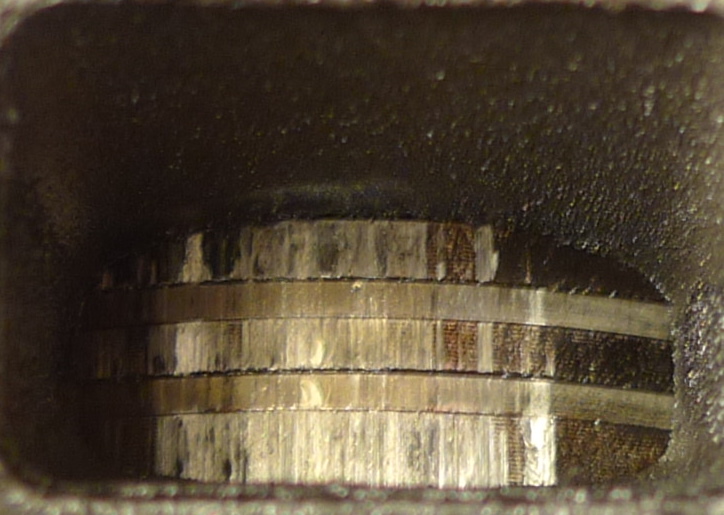

Just flip the black piece around and put it in the other way around.The break free product I used is Aerokroil by Kano Laboratories. Had to order it through the mail after someone recommended it for a bolt in a car rear end that would not give, it worked on that also. Got the saw back together and tried to start it but the pull rope will only pull out half way or less, maybe a third of the way. My 77 year old father took the saw apart and I put it back together so wasn't sure about all the pieces. The little plastic piece that sits over the spark plug will not go all the way down so the outside cover will fit. Also had the small flat piece of steel left over. Not sure where it goes.

IPL calls it a pre-filter, guess it keeps the sawdust out before it can get to the filter..OK on the chain break piece, will see where it fits. The plastic piece is identical size on both sides. Seems to be where you can use the saw vented or unvented. Maybe for different types of weather.

Like in diagram 3?Mine would only go one way. Maybe it's because some of those 290s had a round top and some were flat?. One of my saws also came without that slide that you move with a screwdriver.

Yeah, I didn't think about that when I ordered a couple of them online. I think I ended up trimming one of them to get it to work.Like in diagram 3?

You have to use the right pre-filter, they are different depending on the contour of the top of the saw.

The chain brake is supposed to stop the chain when it is pushed forward, it unlocks when you pull it back. They are supposed to actuate when you have a kickback situation but I never had that happen when I use a saw, maybe I'm more careful than many..I'm not sure I understand the chain break. What I am talking about is when the guard that protects the your top hand, when cutting if I hit that guard on the tree, it pushed backwards and locks the chain. I don't intentionally use it, just happens while using the saw. Also when the saw is being moved around when not in use I will sometimes hit the hand guard by accident and engage the brake. It's not something I use on purpose.

I've had several different kinds of the 390 lines and the Chinese ones were the worst. I bought an Oregon fuel line from a local shop and it seemed to not kink and I assume Stihl has their problem worked out? I guess an easy way would have been to put a metal or plastic elbow there.Actually, Stihl had a major problem with their fuel lines. They would develop cracks between the carb and tank.

Enter your email address to join: