ssm1699

ArboristSite Operative

I may just order an HO pump or 2, regardless.

I'm intrested in a HO oiler do you have the link handy?Just ordered 2 HO pumps, so that I have a backup.

I'm intrested in a HO oiler do you have the link handy?

Link works thank you sirThis should be it. This is what I ordered atleast.

https://www.ebay.com/itm/Oil-Pump-Gear-for-Stihl-066-MS660-Replaces-1122-640-3201/112883422544?_trkparms=aid=111001&algo=REC.SEED&ao=1&asc=20160727114228&meid=85bcd511d68c4f2f8bc895fd9c5cd07a&pid=100290&rk=1&rkt=4&sd=112883422544&itm=112883422544&_trksid=p2060778.c100290.m3507

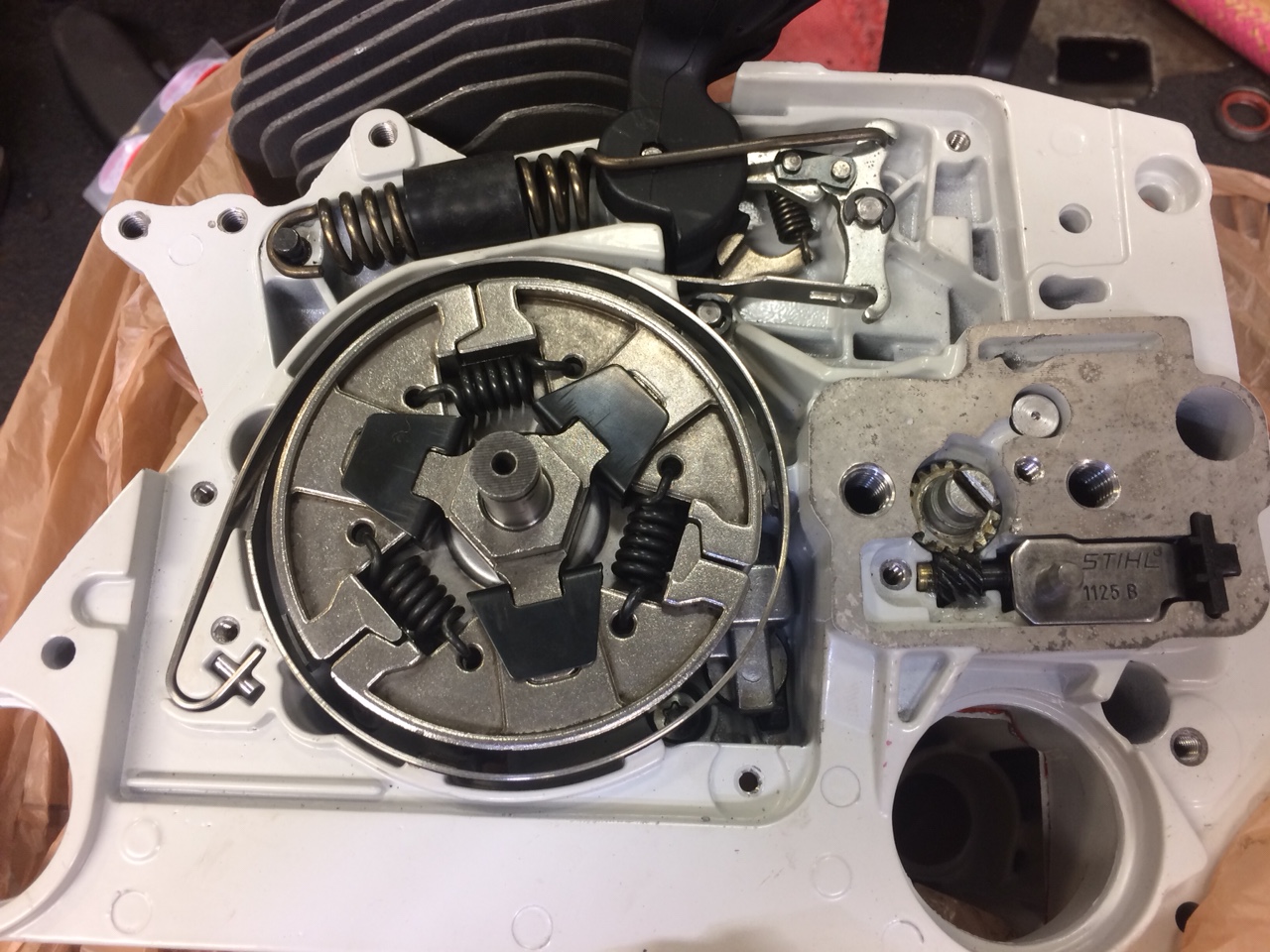

Congrats. It's a good feeling when it fires up for the first time isn't it?Well, I haven't tuned it. But I have fired my saw and man does it sound and feel good. We will see how it goes as it breaks in, but I am running it without a decomp right now. It isn't bad to start as is. But like said, it also isn't broke in yet, of which may change things for me. I am in "small engine heaven" today. Got the 660 running and also got my fs85r running. Been fighting it for over a month. Love how it is running too. It was another project I have been working on, along side the 660 build.

Sent from my LGUS992 using Tapatalk

It is great. And it did the initial pop on the second pull. Full running on about the 5th. It doesn't have high idle, so I need to take care of that issue. But the carb is set almost perfect, by a tach. Pulled to 12k, with the way the carb is set. I may still open up the jet on the carb. But just purrs at idle and pulls right up with the trigger pull.Congrats. It's a good feeling when it fires up for the first time isn't it?

Sent from my Moto G (4) using Tapatalk

It is great. And it did the initial pop on the second pull. Full running on about the 5th. It doesn't have high idle, so I need to take care of that issue. But the carb is set almost perfect, by a tach. Pulled to 12k, with the way the carb is set. I may still open up the jet on the carb. But just purrs at idle and pulls right up with the trigger pull.

Sent from my LGUS992 using Tapatalk

All of the Farmertec kits (7) have been a ‘no fast idle’ for me.

They never get the throttle link right. [emoji849]

What is the fix to get it working?

Sent from my Moto G (4) using Tapatalk

I'm running two BB jugs on my mill saws. They both have almost an entire 36" chain sharpened through them. Haven't had one single issue with either (besides recoil assemblies blowing up about a year ago). Like stated above, you "need" to use the base gasket to minimize the Freeport. With the gaskets installed, I can just make out the bottom of the skirt at top dead center. As far as the parts that have "issues" and "maybe should" be replaced, that is up to you. As you read through the thread, you will see A LOT OF INFO. There really isn't any "right or wrong", except to say that the decomp needs to be replaced with a plug, OEM or Husky, the chain adjuster "needs" to be shimmed no matter wether you use the kit screw or OEM, I "feel" you NEED OEM bar studs, kit carb either works fine or doesn't tune (replace with Walbro if it is a problem). Other than that, the rest is up to you. I run Caber rings, OEM decomp, OEM chain adjuster shimmed, OEM bar studs, Walbro wj76 carb on one and kit carb on another, basic woods port, 1184 on the sealing surfaces, rip out the seals and install new after the cases are pressed together and have 4 recoil assemblies on hand, but haven't blown one in 8 months and run the HO oil pump on both.Hey all, newb here. Getting ready to start my first FT660 build, and totally geeking out on all the great info here.

I have not came across any info on what effect using a big bore piston and cylinder has on the balance of the engine. Is this something that needs to be addressed?

Enter your email address to join: