I've had this saw a couple years, have maybe 10 hours on it. I had a tree start falling but only tilted 10 or 15 degrees before it became entangled on those around it. Long story short I got the saw stuck while cutting through the remaining wood fibers between the notch and the back cut. No problem, I attached the tow rope to the tree and snatched it off the remaining log. I have no idea how physics managed to let this happen but the saw fell, flipped under the tree, and was.. piledriven?

I'm attempting to revive this one before I commit to getting the MS261 I've been wanting. If the engine on the damaged MS271 is repairable within reason I'll look into getting a new handle and some new plastics.

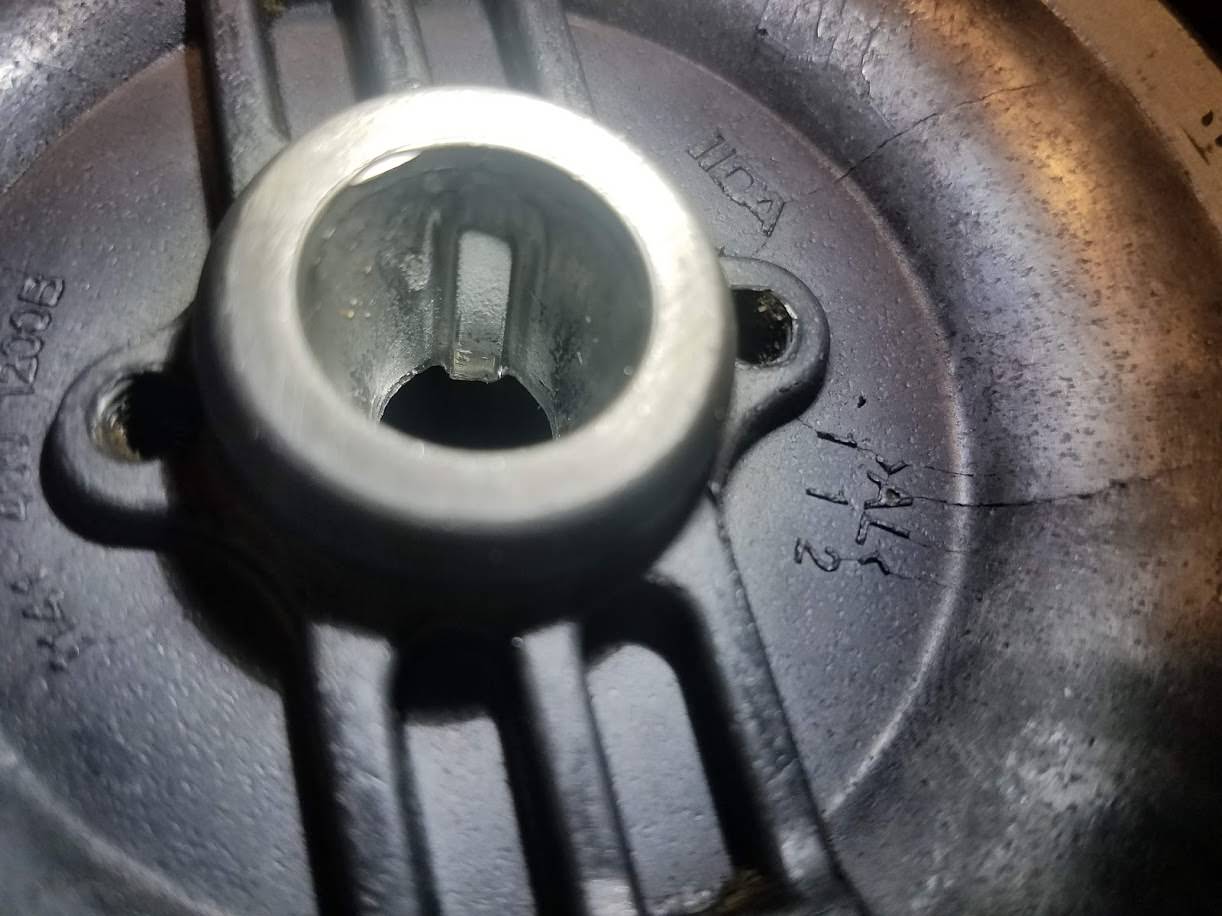

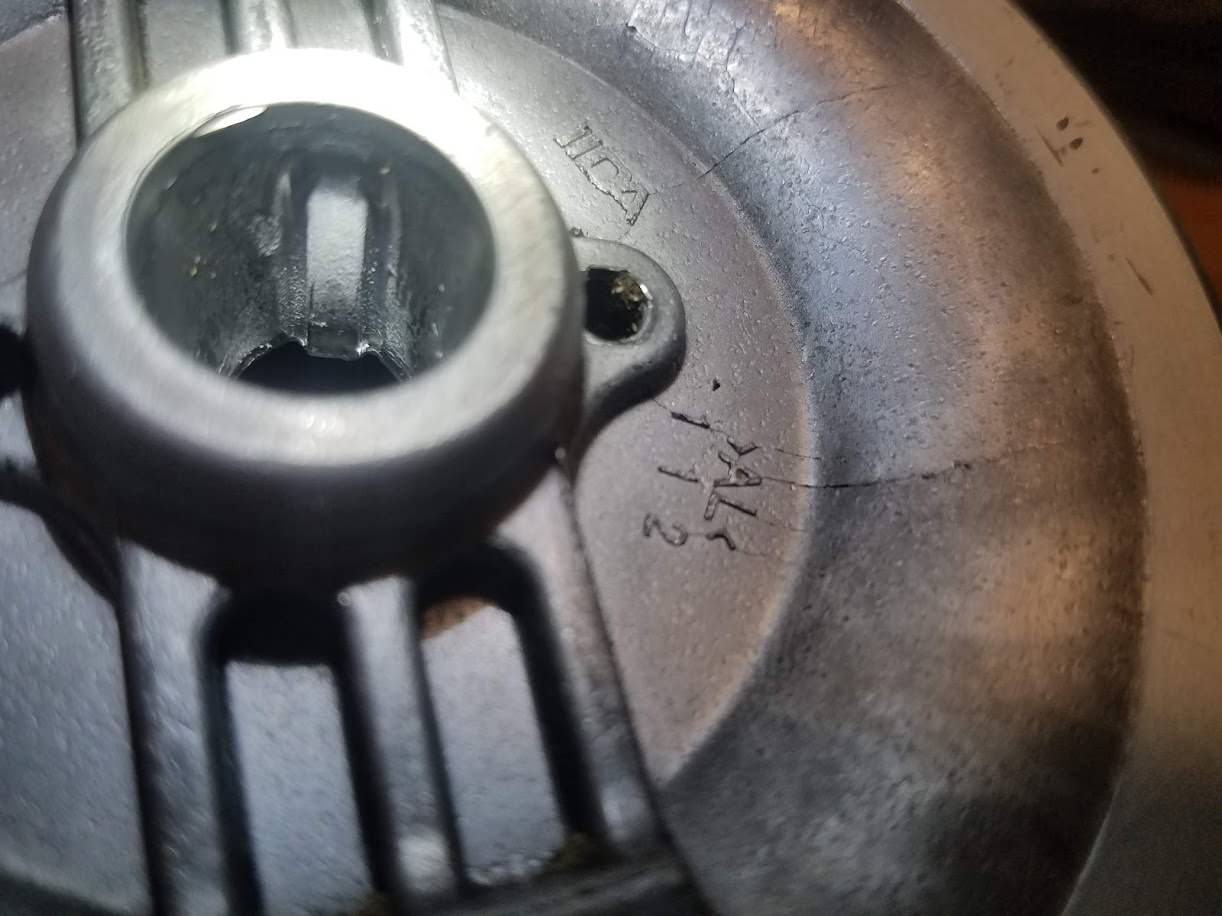

When I attempt to turn the engine over there is more resistance than there was before. Seems like it is only in one spot, aligns perfectly with the compression stroke. I stripped the powerhead down and I can tell when I slowly turn the engine over by hand that the flywheel has a high spot. In other words the distance from the engine to the edge of the flywheel varies as the engine is turned over.

How can I determine whether the flywheel is bent or if the crankshaft is bent? If it is the crank I would be tempted to bang on the high spot with a piece of wood to attempt to straighten it and get some more life out the powerhead. Depends on the cost of a crank I guess. Any input is appreciated!

I'm attempting to revive this one before I commit to getting the MS261 I've been wanting. If the engine on the damaged MS271 is repairable within reason I'll look into getting a new handle and some new plastics.

When I attempt to turn the engine over there is more resistance than there was before. Seems like it is only in one spot, aligns perfectly with the compression stroke. I stripped the powerhead down and I can tell when I slowly turn the engine over by hand that the flywheel has a high spot. In other words the distance from the engine to the edge of the flywheel varies as the engine is turned over.

How can I determine whether the flywheel is bent or if the crankshaft is bent? If it is the crank I would be tempted to bang on the high spot with a piece of wood to attempt to straighten it and get some more life out the powerhead. Depends on the cost of a crank I guess. Any input is appreciated!