MarkEagleUSA

ArboristSite Guru

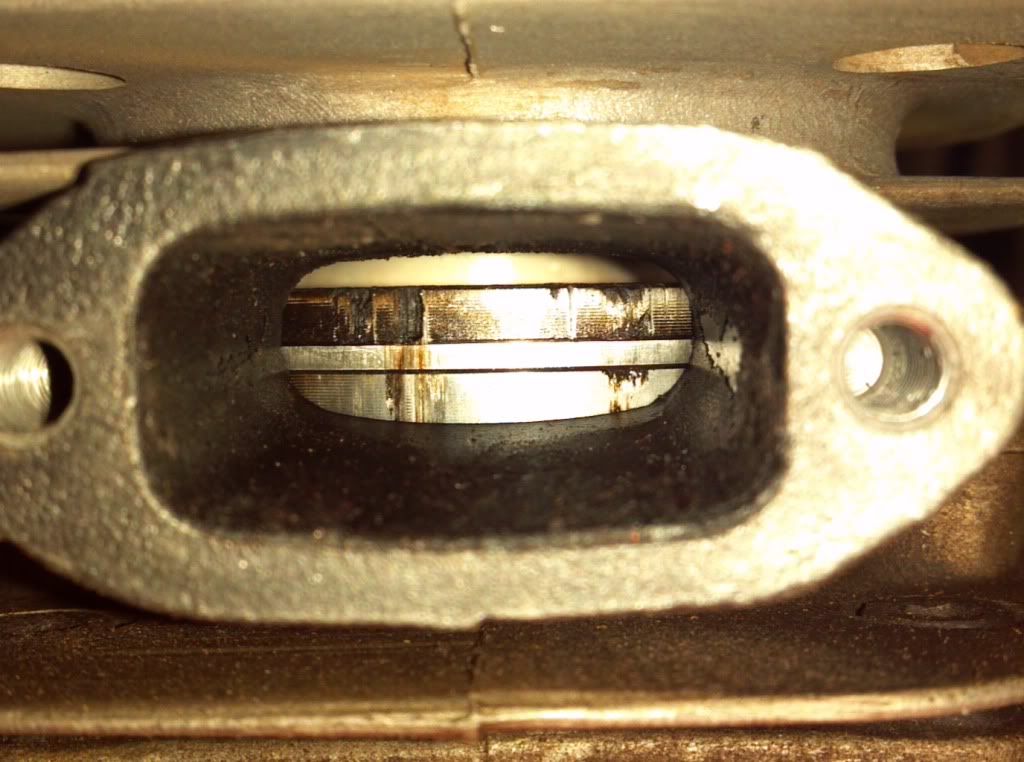

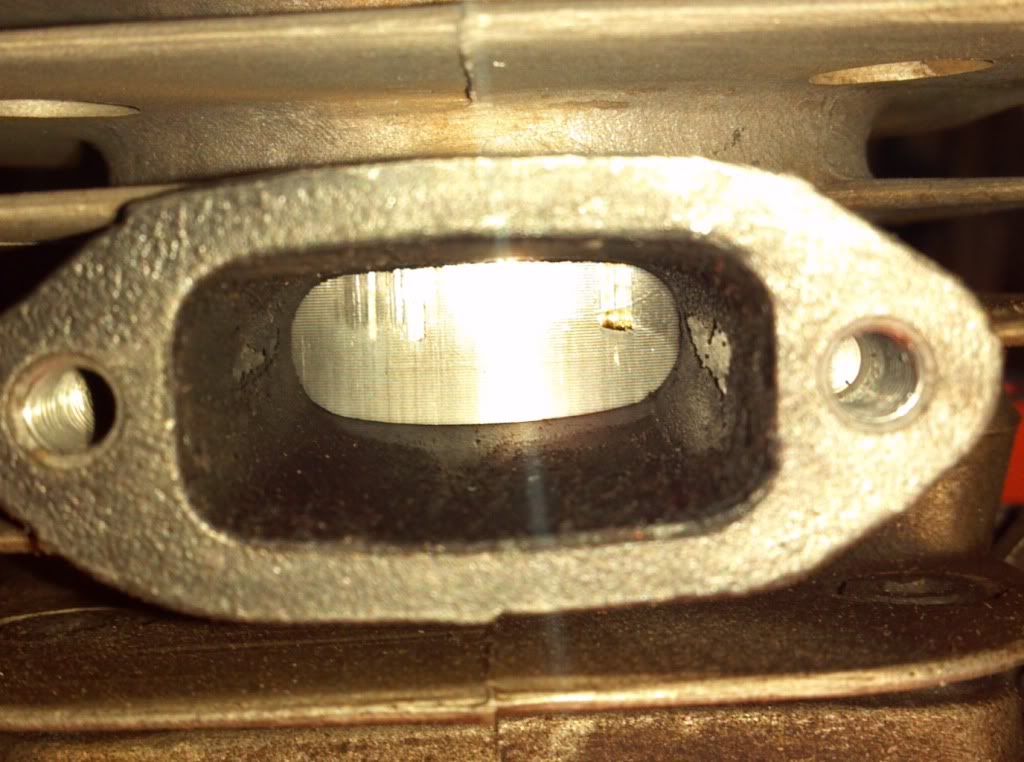

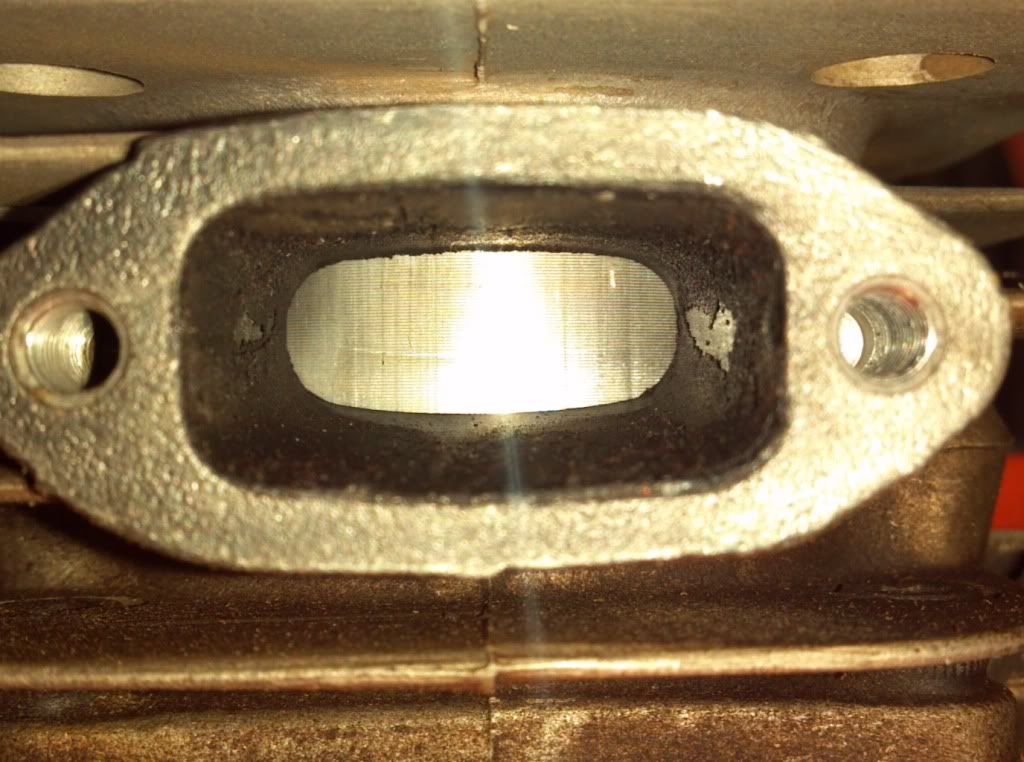

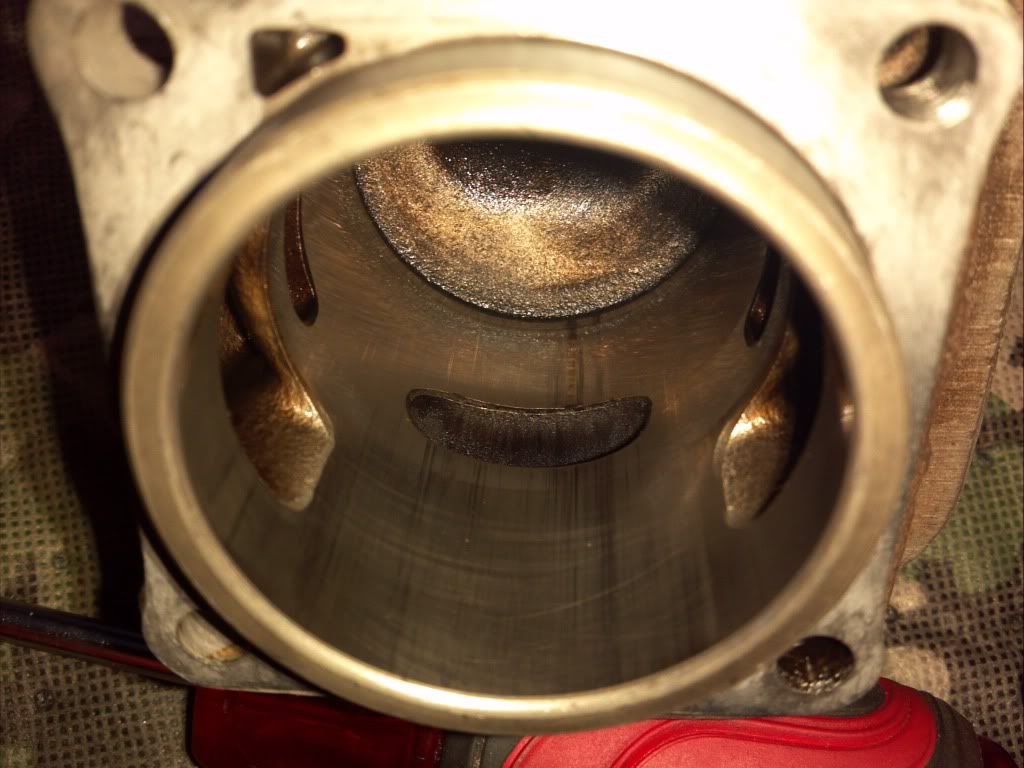

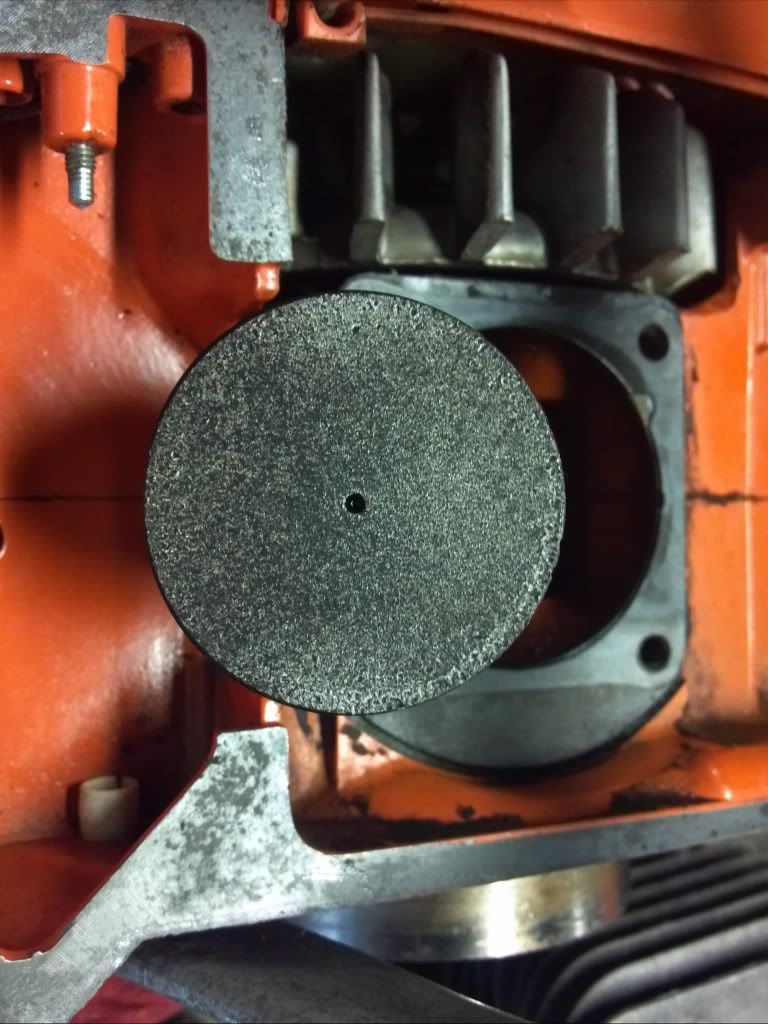

I removed the muffler on my 162SE to paint it last night and was horrified to see the upper portion of the piston (the part that travels above the exhaust port) has some minor scoring. This is new since it wasn't there a couple of months ago when I got the saw running after a fuel line replacement and carb rebuild.

I just replaced the oil pump and think the seal in the old one went bad as it was leaking oil from behind the clutch. After putting the new pump in I tried to start it and it wouldn't run. Upon throttle up it would spit and sputter but never get to full RPM. Had to really lean it out to get it to run but wasn't comfortable with that (not sure if that's what caused the scoring; I only ran full throttle for about 5 seconds).

Anyway, as I said the scoring is only on the side of the piston that travels above the exhaust port. What should my next step be? Obviously at some point I need to tear it down to check the cylinder. I guess a vac/pressure test is in order?

I also did some searching for a replacement P&C but came up empty. It seems though that parts from a later 61 will fit... is this true? If it needs to be rebuilt I guess I'd like to update the crank to a more current fine-threaded one but don't know where/how to start.

I just replaced the oil pump and think the seal in the old one went bad as it was leaking oil from behind the clutch. After putting the new pump in I tried to start it and it wouldn't run. Upon throttle up it would spit and sputter but never get to full RPM. Had to really lean it out to get it to run but wasn't comfortable with that (not sure if that's what caused the scoring; I only ran full throttle for about 5 seconds).

Anyway, as I said the scoring is only on the side of the piston that travels above the exhaust port. What should my next step be? Obviously at some point I need to tear it down to check the cylinder. I guess a vac/pressure test is in order?

I also did some searching for a replacement P&C but came up empty. It seems though that parts from a later 61 will fit... is this true? If it needs to be rebuilt I guess I'd like to update the crank to a more current fine-threaded one but don't know where/how to start.