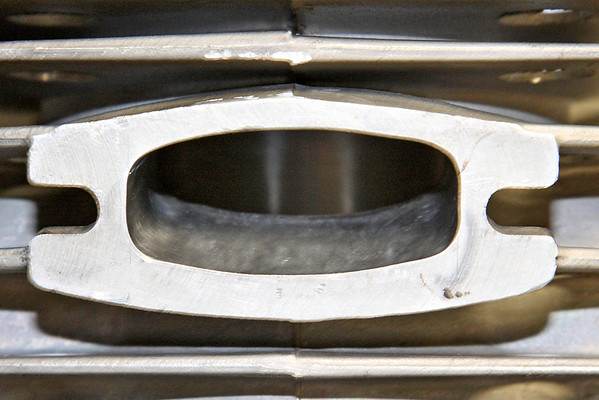

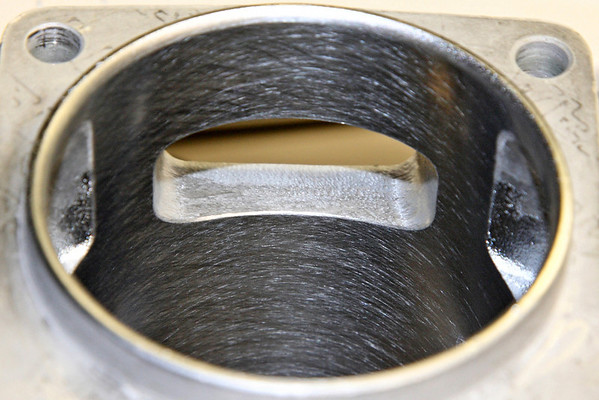

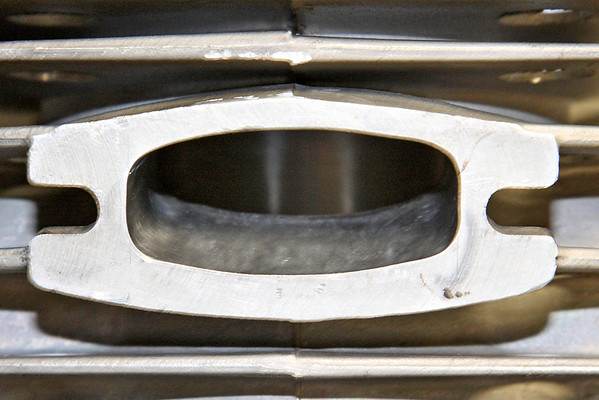

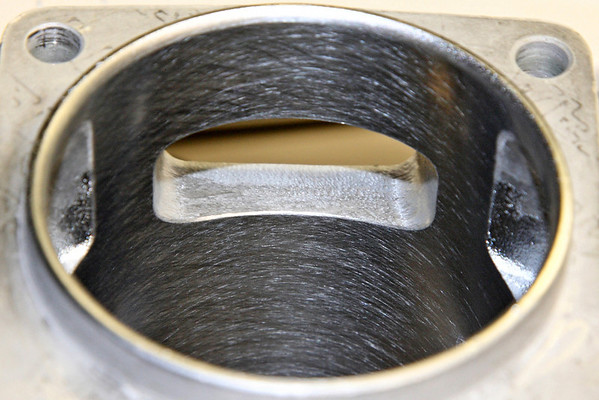

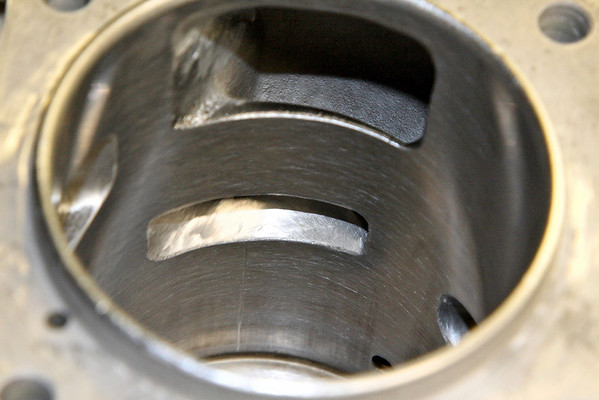

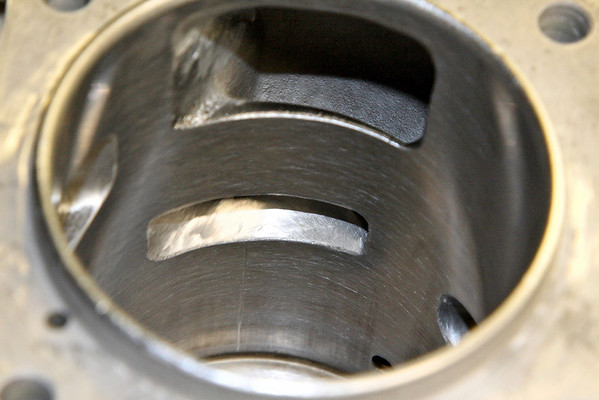

The exhaust port was only 59% of bore diameter

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3120 Gone BAD

- Thread starter blsnelling

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

timberwolf

Addicted to ArboristSite

I think I would say it was a four corner siezure. Run hard with no warm up. Likely the timing advance would have been a factor. As much as I have seen timing advances are bandaids for poor portjobs, esp ones where the exhaust port got a little too high.

Looks like you might be able to save it if you drop the jug down a little.

Looks like you might be able to save it if you drop the jug down a little.

I think I would say it was a four corner siezure.

Makes sense to me. Thanks for your input Brian. Keep that in mind you guys like like to rev the daylights out of your saws as soon as they fire up cold. I see it done all the time, and most get away with it. But what's a few seconds if it cost you your saw?

RRSsawshop

ArboristSite Operative

I think I would say it was a four corner siezure. Run hard with no warm up. Likely the timing advance would have been a factor. As much as I have seen timing advances are bandaids for poor portjobs, esp ones where the exhaust port got a little too high.

Looks like you might be able to save it if you drop the jug down a little.

:agree2: Seen it alot on old air cooled dirt bikes,kids would start them up and go "trash them" and have a cold seizure..

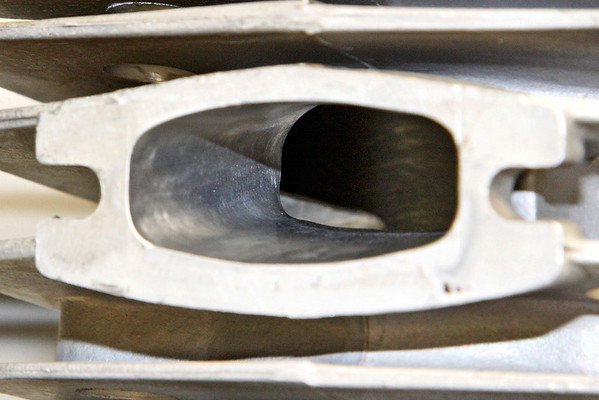

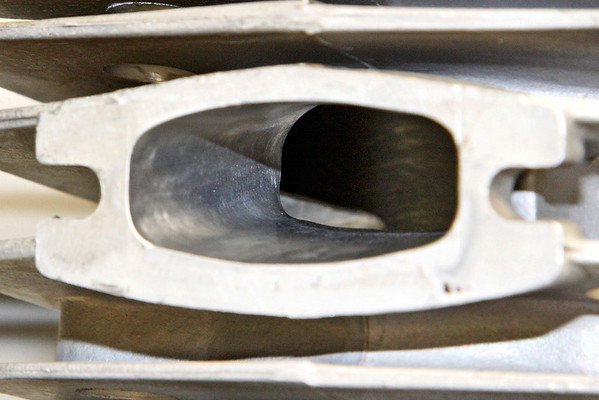

That crossed my mindTransfers are too high for a pipe though, at least from what I've read.

I worked on a saw done by the same builder (Jonsered 2186). The exhaust port was tall and the transfers were too high. Blowdown was about 18 degrees. I wasn't able to make it much of a runner without a new jug. Exhaust duration was around 185°. The porting work looked identical to the 3120 jug pictured.

Former Saw Builder

ArboristSite Guru

- Joined

- Oct 8, 2005

- Messages

- 903

- Reaction score

- 177

I worked on a saw done by the same builder (Jonsered 2186). The exhaust port was tall and the transfers were too high. Blowdown was about 18 degrees. I wasn't able to make it much of a runner without a new jug. Exhaust duration was around 185°. The porting work looked identical to the 3120 jug pictured.

JJ I think you meant same BUTCHER not builder.... That was a horrible port job.

The cylinder's done. I've yet to work over the piston windows.

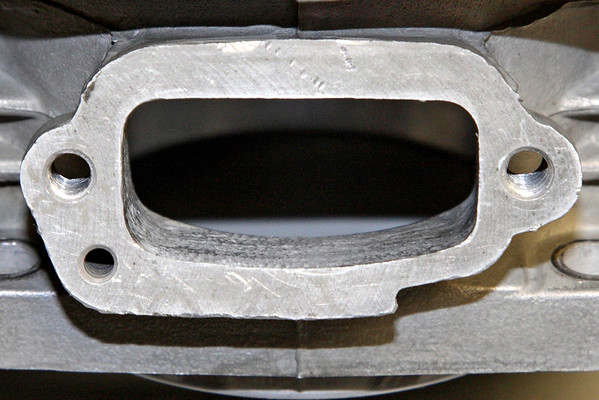

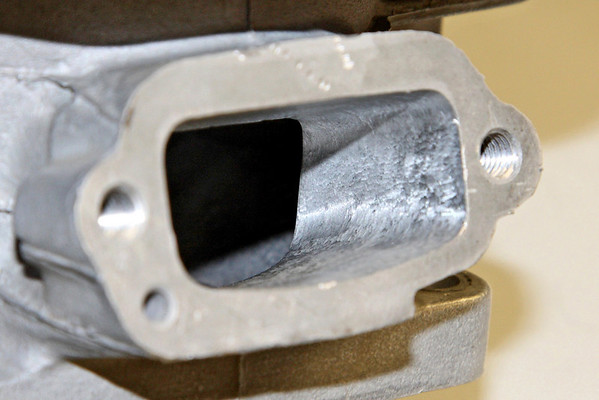

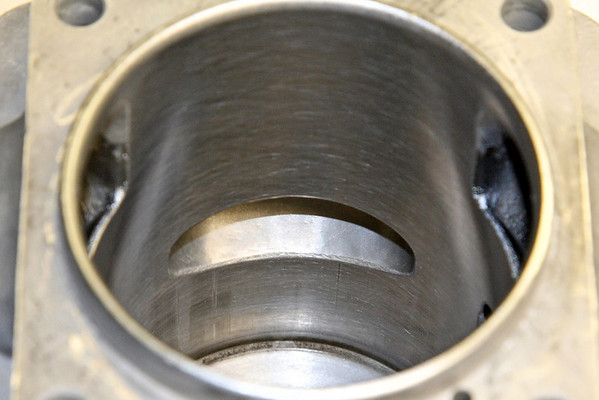

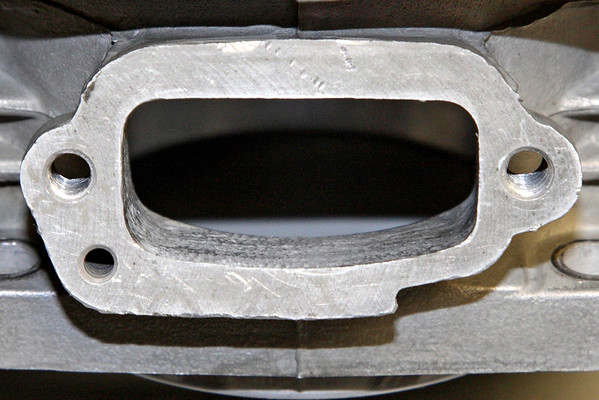

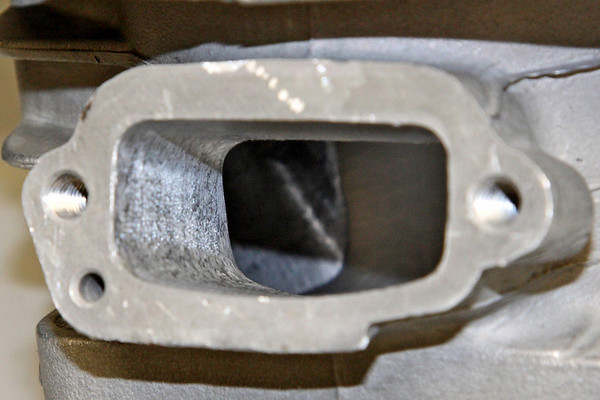

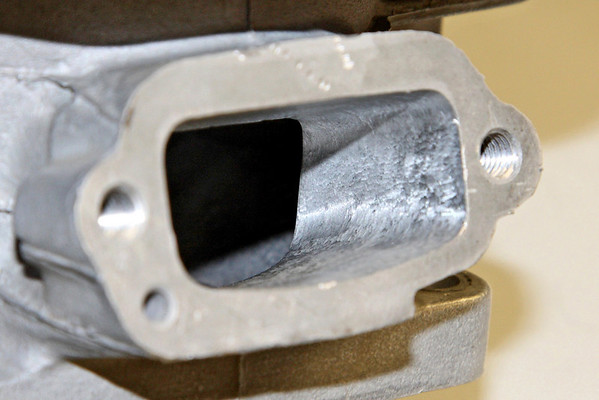

I widened the exhaust to piston skirt limits. I could not go quite 70%. I tapered everything out towards the flange to flatten the walls out. I also kept the port sides straight at the cylinder wall.

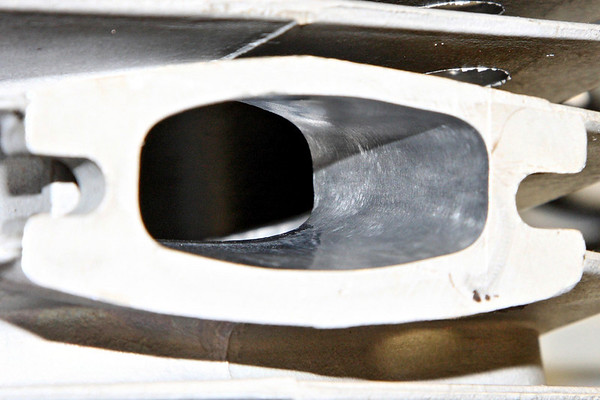

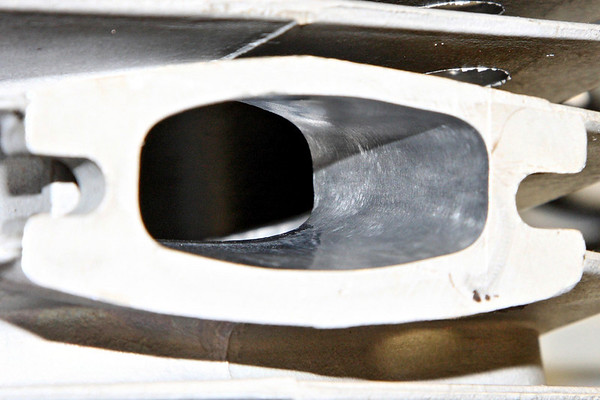

Same with the intake. I ported matched the spigot to the carb adapter. All port walls are flat now.

I widened the exhaust to piston skirt limits. I could not go quite 70%. I tapered everything out towards the flange to flatten the walls out. I also kept the port sides straight at the cylinder wall.

Same with the intake. I ported matched the spigot to the carb adapter. All port walls are flat now.

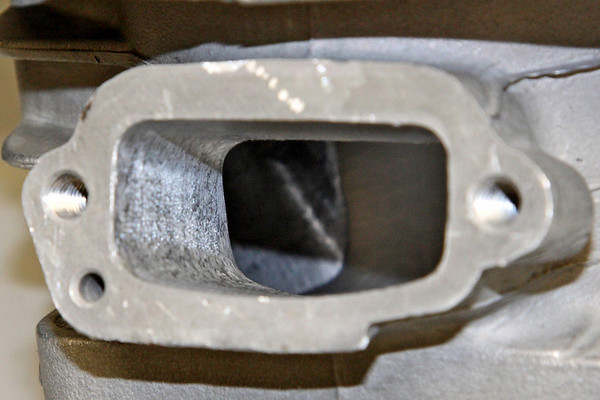

The transfers were the ugliest. There were a couple knicks I didn't quite remove. I didn't want to raise them any more. I did widen them towards the intake.

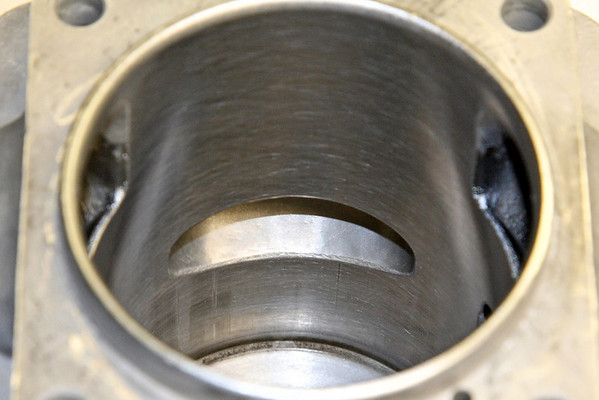

Most of the irregularities in the cylinder wall honed out. It was only a couple quick hones in both directions. I use the 320 grit hones from Baileys. I'm hoping for the best.

Makes sense to me. Thanks for your input Brian. Keep that in mind you guys like like to rev the daylights out of your saws as soon as they fire up cold. I see it done all the time, and most get away with it. But what's a few seconds if it cost you your saw?

That goes for anytime. There is no use for free-reving, besides a little tuning; but you still have to be careful with that even. Rev it for a quick bit to listen for the burble, then let off. Adjust the carb, then recheck. Then use a tach at the end to make sure everything is golden.

Kwdog75

Addicted to ArboristSite

I do it all the time.

But a 3120?

Most of the irregularities in the cylinder wall honed out. It was only a couple quick hones in both directions. I use the 320 grit hones from Baileys. I'm hoping for the best.

Damn, that hone sure does work well.

But a 3120?

My 084 was a total disappointment stock. So yes, even the big boys

But a 3120?

What does it matter. I say people can do what they want as long as they own it. People mod brand new cars all the time. You can say bye-bye to the warranties.

Damn, that hone sure does work well.

I think Jasha hones every cylinder he does. You can see why

Kwdog75

Addicted to ArboristSite

dog,

don't be silly..

you port a saw because it makes it lighter !!!!!!!

really, think about it !!!

Please, i used to balance small blocks for the fast revs but i didn't think about that with saws.

Kwdog75

Addicted to ArboristSite

My 084 was a total disappointment stock. So yes, even the big boys

It's a stihl...hahahaha... just kidding!

It's a stihl...hahahaha... just kidding!

:greenchainsaw: More power!!!

Kwdog75

Addicted to ArboristSite

More power... me like!!

4mocajuns

ArboristSite Operative

SO you won't tell us who did this porting origionally can you at least tell us which ones saws to stay away from? I mean if I bought a used saw that was professionally ported and that is what I got I would be pissed.