You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

357 carb on 346xp

- Thread starter sunfish

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

SawTroll

Information Collector

Must have been an early target max rpm?

My 2001 owner's manual says 14700. And I've heard the NE 346 is a bit lower.

.......

Yep, but it started higher in 1999, as albert stated. The NE is limited at 14,100, and they actually recommended max 14,200 on the OE ones here - probably because they were used for felling as well as limbing.......:msp_unsure:

sunfish

Fish Head

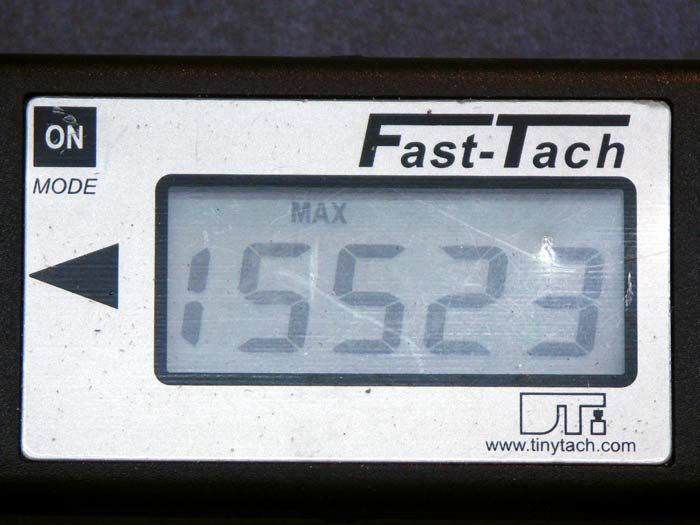

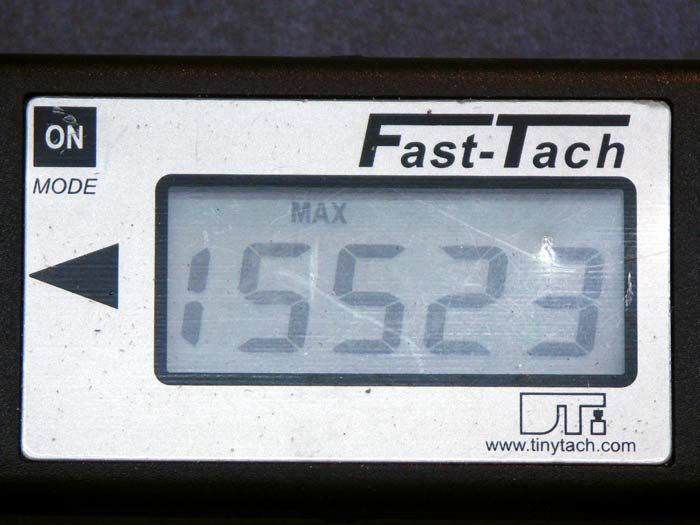

The saw really has a different sound now! :msp_biggrin:

Not much 4 stroke at that rpm, so back it down to 14800-15000 and it rips!

Conclusion, if you port your 346xp, a 357xp carb is not a bad move. :msp_biggrin:

And in my case, it's a direct bolt in, with just a light trim of plastic.

Thanks for the input guys, especially Stump for tellin my to wind it up tighter.

Not much 4 stroke at that rpm, so back it down to 14800-15000 and it rips!

Conclusion, if you port your 346xp, a 357xp carb is not a bad move. :msp_biggrin:

And in my case, it's a direct bolt in, with just a light trim of plastic.

Thanks for the input guys, especially Stump for tellin my to wind it up tighter.

Last edited:

MacLaren

Addicted to ArboristSite

Congrats Don! You did a helluva job!

sunfish

Fish Head

Congrats Don! You did a helluva job!

Thanks man, but not that big a deal. Video would help, but I don't do vids. Maybe we'll have moving pictures at the next GTG.

I was already happy with how the saw ran, just wanted to try the larger carb (temporarily), but I think I'll leave it on there. :msp_biggrin:

Last edited:

sunfish

Fish Head

Good job, is 15k where it seemed the strongest? Hows the tourque compared to the stock carb?

Seems strongest around 14800-14900. I'd say torque is about the same as stock carb, but it's cuttin faster with the higher rpm and it's holding rpm real good. Holding around 10800 in the cut with good pressure on it, 16" bar buried in oak. It definitely feels stronger now (leaner), than when it was set richer.

logging22

Cuttin to live, livin to cut

Awesome job Don. You da man!

sunfish

Fish Head

Awesome job Don. You da man!

Thanks big guy!

Might go back into it for more grindin, and or see if I can talk Stumpy into weld up a pop-up.

Dang, this is gettin out of hand. :msp_biggrin:

komatsuvarna

Arboristsite MVP

Dang, this is gettin out of hand. :msp_biggrin:

Just wait lol!!!

:msp_wink:

Why weld a popup and add weight when you can turn a popup into the stock piston?

sunfish

Fish Head

Why weld a popup and add weight when you can turn a popup into the stock piston?

Just exploring the possibilities, Brad.

Actually, I have lathe... :msp_smile:

Last edited:

Why weld a popup and add weight when you can turn a popup into the stock piston?

Please explain....welding and creating a pop-up would increase the compression ratio and cranking compression....by turning a stock piston into a pop-up wouldn't you be lowering the CR? Is the stroke, rod length, or pin height changed somehow to make a turned piston work?

thanks.

sunfish

Fish Head

Please explain....welding and creating a pop-up would increase the compression ratio and cranking compression....by turning a stock piston into a pop-up wouldn't you be lowering the CR? Is the stroke, rod length, or pin height changed somehow to make a turned piston work?

thanks.

After ya turn a pop-up, you take the same off the bottom of the cylinder. This put the pop-up into the combustion chamber.

sunfish

Fish Head

Cool, thanks...still learing about these things. All my experience prior to this is automotive.

Heck, I'm still learnin and have lots to learn!

logging22

Cuttin to live, livin to cut

Info galore around here. Trying to keep up.:biggrin:

Stumpys Customs

Stumpbroke

3/4 of a piece of alluminum filler rod don't wiegh that much, unless yer from Norway. Why go with a .030" popup when you can go .100" & really wake it up, also allot less work involved. I know the 372's like it. Different strokes fer different folks.

Now sit back & watch the can-o-worms explode:msp_ohmy:

Now sit back & watch the can-o-worms explode:msp_ohmy:

BloodOnTheIce

Addicted to ArboristSite

I did this carb swap along with the flattop 353 piston to my ported Husky 350, it's a real budget runner. Parts, saw, bar and chain I have under 200$ into the saw.

sunfish

Fish Head

3/4 of a piece of alluminum filler rod don't wiegh that much, unless yer from Norway. Why go with a .030" popup when you can go .100" & really wake it up, also allot less work involved. I know the 372's like it. Different strokes fer different folks.

Now sit back & watch the can-o-worms explode:msp_ohmy:

I'm with ya Stumpy. Two different schools of thought and both work.

Could turn a .030" pop and add another .050-.070" by welding. :msp_smile:

Similar threads

- Replies

- 1

- Views

- 523