mikeb1079

ArboristSite Operative

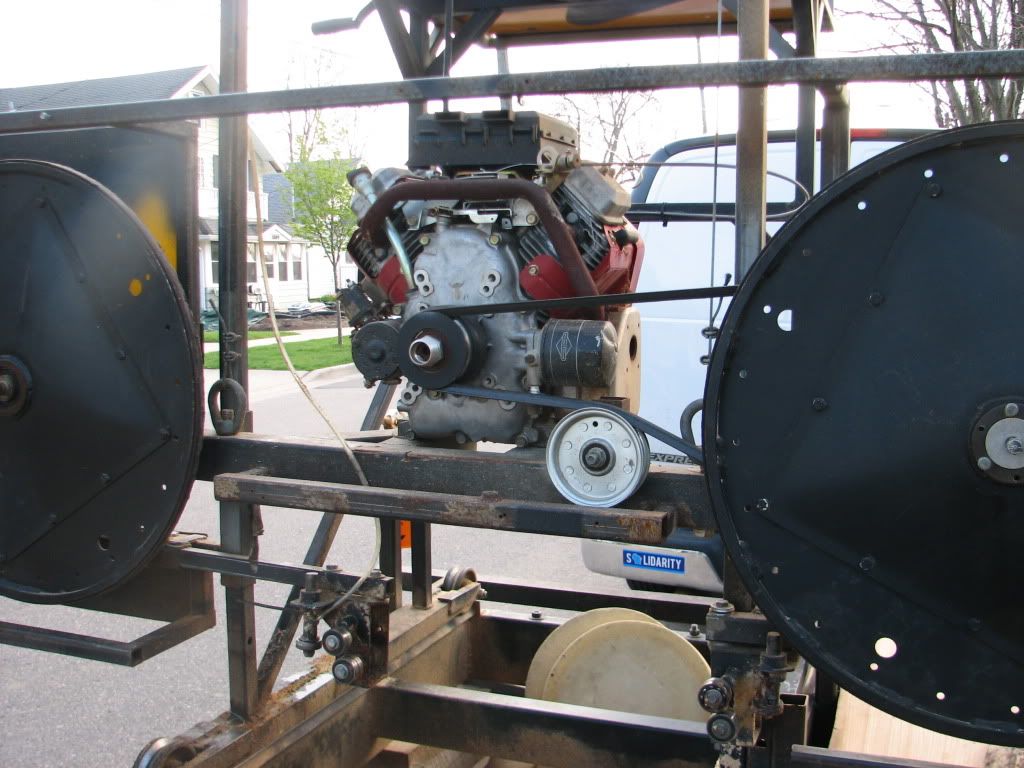

hey fellas had a great day milling today figured i'd share some pics. the first log was a gnarly american elm chunk that i whittled (massacred really) down to fit on the mill. man my freehand chainsawing needs some work!

i took a few slab cuts to make a cant. here i got er cut down a bit. typically to set my depth of cut i just use a combination square and make a tic mark. i cut this elm at 4/4 and a few 8/4.

this pic is too close up but i got some nice vertical grain elm boards out of it.

then on to one of the last quarters of a giant walnut log i picked up last summer. a few clean up cuts and it turned into a nice pie wedge.

some really nice qsawn pieces out of this. probably 10-12" wide. then a fella i know stopped by with some smaller apple logs and we cut em up. cut nicely, very very fragrant. smelled fantastic, almost like an organic version of tang. the upper logs had a pinkish color but the butt log had much more brown heartwood, very pretty.

the upper logs had a pinkish color but the butt log had much more brown heartwood, very pretty.

he took all the apple home, but by the end of the day i had a nice little pile of lumber to sticker. :msp_smile:

hope you enjoyed the pics.

i took a few slab cuts to make a cant. here i got er cut down a bit. typically to set my depth of cut i just use a combination square and make a tic mark. i cut this elm at 4/4 and a few 8/4.

this pic is too close up but i got some nice vertical grain elm boards out of it.

then on to one of the last quarters of a giant walnut log i picked up last summer. a few clean up cuts and it turned into a nice pie wedge.

some really nice qsawn pieces out of this. probably 10-12" wide. then a fella i know stopped by with some smaller apple logs and we cut em up. cut nicely, very very fragrant. smelled fantastic, almost like an organic version of tang.

the upper logs had a pinkish color but the butt log had much more brown heartwood, very pretty.

the upper logs had a pinkish color but the butt log had much more brown heartwood, very pretty.

he took all the apple home, but by the end of the day i had a nice little pile of lumber to sticker. :msp_smile:

hope you enjoyed the pics.