Bowtie

Gearhead

But... after the Govt gives Brad/wife $1200 in July, it's only a $400 saw!

HEY, THATS RIGHT!!! Theres my excuse to get a 660!!!!!!

But... after the Govt gives Brad/wife $1200 in July, it's only a $400 saw!

But... after the Govt gives Brad/wife $1200 in July, it's only a $400 saw!

But... after the Govt gives Brad/wife $1200 in July, it's only a $400 saw!

HEY, THATS RIGHT!!! Theres my excuse to get a 660!!!!!!

And you'll have change... to take the wife out for a burger in exchange for her $600..

Sorry Brad, I had to LMAO at that one!

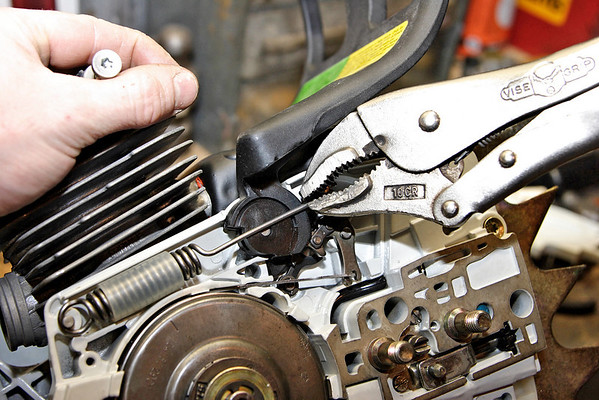

Sorry Brad, I had to LMAO at that one!Even with a good sized set of ViseGrips, this is still not easy.

Oh boy... that's how to get hurt.

There's an amazingly simple and cheap tool to do that job... Aren't you looking in the service manual?

Hook spring on right side. Move left spring end to left post with tool, over post, rotate tool, and you're done... Used on almost all Stihls.

i bet a fellow could make that tool himself with a grinder and a dremel tool?

It's just a hardened steel tube with 180 degrees cut out on the end. You place it over the post while it holds the spring, then rotate it and it releases the tool, and leaves the spring against the post.

So its the Govt that is donating to his addiction........Hmmmmmm..

.

Wow, you guys are really bustin on ole Brad tonight!...

It's just a hardened steel tube with 180 degrees cut out on the end. You place it over the post while it holds the spring, then rotate it and it releases the tool, and leaves the spring against the post.

It's just a hardened steel tube with 180 degrees cut out on the end. You place it over the post while it holds the spring, then rotate it and it releases the tool, and leaves the spring against the post.

Oh boy... that's how to get hurt.

There's an amazingly simple and cheap tool to do that job... Aren't you looking in the service manual?

Hook spring on right side. Move left spring end to left post with tool, over post, rotate tool, and you're done... Used on almost all Stihls.

I have a pair of automotive brake spring pliers that I use. One handle

end of pliers is just what Lake described.

Just add that part number to your order!

And.. the clutch spring install tool.. very cheap..

Enter your email address to join: