Next I'll make a roughly shaped packing piece and gorilla glue to the back, once dry I'll finish the fit then cut the kerf and whack a wedge in....should get around to that before the end of the decade.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Axe restoration thread

- Thread starter svk

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Beauty of a hatchet. Sure is a pretty design.

It's not that bad of a crack and its better that it's where it is.

I like the idea of drilling a hole and making a dowel to glue into it to keep it from splitting further.

You could even use a nice contrasting wood like Walnut or Chestnut for the dowel.

As for the head, I'd leave it just how it is. Just put an edge back on it with files and stones.

Make sure you post some more pics of the progress.

Thanks for the compliments, I fell in love with it at first site. I believe it has the original handle as the others I have looked at online have the exact same shape. I have sanded it and applied 4 coats of BLO on her, they are still soaking in completely dry in 20 min. As for the crack it appears better after a few coats, will wait to see if it opens up after a little use. Just may do the dowel rod treatment to preserve the original 100 year old handle. Not sure what wood it is, looks like hickory to me but when I sanded it was a shade of brown all the way through. It also had a funny smell to the wood dust, kinda familiar but can’t recall where I have smelled it before. More pics coming soon.

Sent from my iPhone using Tapatalk

Marine,

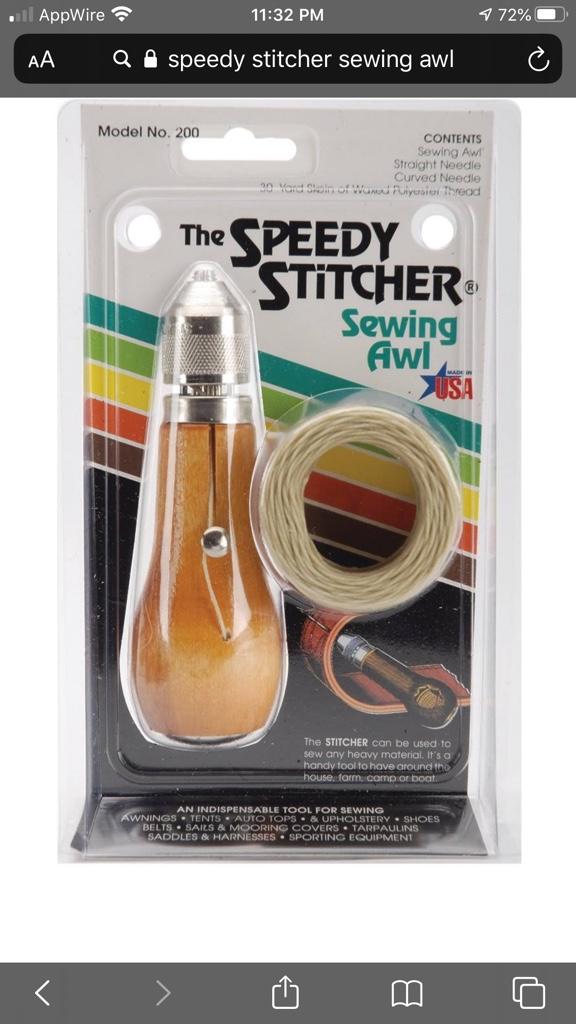

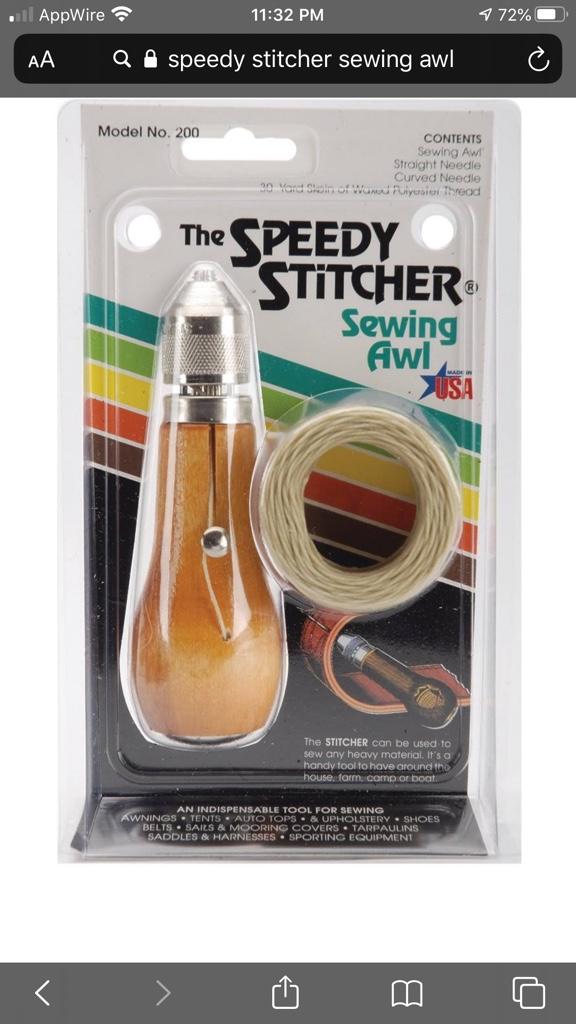

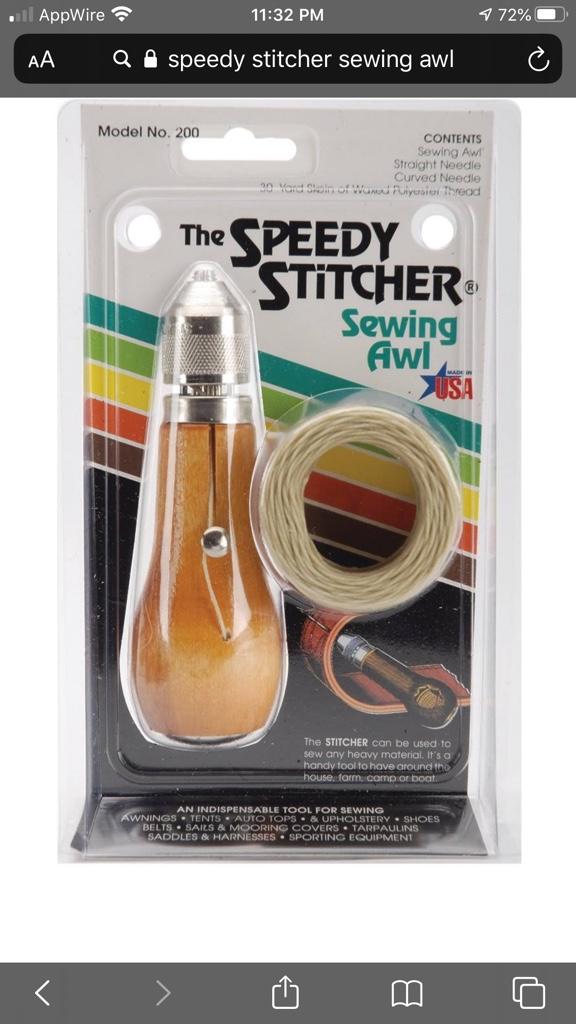

As for the sheath making, I have made one from old boot leather for my X27. I used a speedy stitcher and some copper rivits from a hardware store. You can do it!

Sent from my iPhone using Tapatalk

As for the sheath making, I have made one from old boot leather for my X27. I used a speedy stitcher and some copper rivits from a hardware store. You can do it!

Sent from my iPhone using Tapatalk

My friends are moving to Florida, and have to be out of their house by the end of the month. They literally filled my truck up with rakes, shovels, digging bars, a 5 "HP" 20 gallon air compressor, a big steel milk can, a bigger white crock with blue makers Mark, and these two axes. The double is a Keen Kutter, Made in the USA, and the single is a Craftsman. The Keen Kutter is in real nice shape and I'm sure it has the original wood in it.

I applied the 5th coat to the sledge tonight and it is the first time there was enough to wipe off with a rag after 20 minutes (but only barely enough to dampen the rag.) Another coat or two and I think I'll call it done.I have sanded it and applied 4 coats of BLO on her, they are still soaking in completely dry in 20 min.

Neil, what ever happened with that old beat up Jersey?

I have an awl that looks just like that, that was my grand fathers. Mine is over 100 years old. Well not exactly like that. The handle is a little longer, and the fat end unscrews for storage of different needles.Marine,

As for the sheath making, I have made one from old boot leather for my X27. I used a speedy stitcher and some copper rivits from a hardware store. You can do it!

Sent from my iPhone using Tapatalk

Here's the sheath for my wife's, grandfathers American Beauty. It is riveted with copper rivets all the way around. If you see the one rivet on the opening, just inside the flap on the right? It's just enough that the axe will not slip in and out. You have to slide the blade in at an angle to get it to go in. Then the clip on the left secures it well. I don't know if this sheath came with the axe or is home made, they are both about 100 years old also.I plan on making some out of thick leather for my other doubles. I like stitched sheathes with flaps and a snap for belt hatchets and cruisers. I like the heavier leather and rivets for doubles and big choppers and fellers.

All of the years I spent with my son in the Scouts, we did a good bit of leather work. Don't let it scare you, it's pretty easy once you get the hang of it. The only belt I have that fits me is one I made at Scout Camp. I knew I'd expand some as I got older, just didn't plan on expanding as much as I have. If I ever get around to making some sheathes, I plan on getting a set of stamps, and stamping the make of the axe on the matching sheath. All of the stamps to make the patterns you see on holsters, belts and stuff are available at craft stores, so you can make a fancy one. It really is easy.

If anyone gets the urge to make a sheath, one thing I was going to try, is put the sheath with the axe in it, in a vacuum bag and suck the air out. That should get the imprint of the axe in the leather so it looks like a custom fit. The one on the American Beauty above has that imprint just from sitting in the sheath for many years.

Here’s what the handle looks like on the Keen Kutter I recently found, 5 coats in and starting to feel good.

Look at those fat cheeks!

Sent from my iPhone using Tapatalk

Look at those fat cheeks!

Sent from my iPhone using Tapatalk

Still got it and its still not hung. very very embarrassed!. just after i got it I got a wetterlings and another and somehow got into a spin thinking perhaps i should use the curved haft i had started to hang it on, on the wetterlings instead and get a straight haft for the jersey. my reasoning was the jersey with its large and a bit beat up poll, makes a nice wedge banger and a straight haft would be better for that....so i went hunting and found it hard to find a decent straight haft. it then slipped down the list of jobs.Neil, what ever happened with that old beat up Jersey?

I know i'm carp at getting these jobs done. I blame 2 (very soon to be 3) kids under 5!

I'm still waiting on the transatlantic postmen doing there good stuff too.

had an idea, but not sure if it would work. instead of paracord as an overstrike protector has anybody tried a bit of wire, like garden wire maybe, probably a bare/galvanised type?

this sort of thing https://www.gsproducts.co.uk/1-25mm...k_SpT-R1GeJoh074o-ZcSC1nuUCu1uFAaAu2HEALw_wcB

a single strand steel wire...thin enough to wind nice and tight around the haft, but as tick as can be wound neatly so it is hopefully nice and robust. can't quite think how to finish it/tie it off so it stays tight and doesn't stick out....solder the end few coils I guess, fluxed cored welding rod of some kind and a butane torch? galvanised could be a problem though? anybody got any experience on welding/brazing/solder rods, or garden wire?

this sort of thing https://www.gsproducts.co.uk/1-25mm...k_SpT-R1GeJoh074o-ZcSC1nuUCu1uFAaAu2HEALw_wcB

a single strand steel wire...thin enough to wind nice and tight around the haft, but as tick as can be wound neatly so it is hopefully nice and robust. can't quite think how to finish it/tie it off so it stays tight and doesn't stick out....solder the end few coils I guess, fluxed cored welding rod of some kind and a butane torch? galvanised could be a problem though? anybody got any experience on welding/brazing/solder rods, or garden wire?

If I were going to try something like that I would consider stainless steel safety wire and twist the ends with the safety wire pliers.had an idea, but not sure if it would work. instead of paracord as an overstrike protector has anybody tried a bit of wire, like garden wire maybe, probably a bare/galvanised type?

this sort of thing https://www.gsproducts.co.uk/1-25mm...k_SpT-R1GeJoh074o-ZcSC1nuUCu1uFAaAu2HEALw_wcB

a single strand steel wire...thin enough to wind nice and tight around the haft, but as tick as can be wound neatly so it is hopefully nice and robust. can't quite think how to finish it/tie it off so it stays tight and doesn't stick out....solder the end few coils I guess, fluxed cored welding rod of some kind and a butane torch? galvanised could be a problem though? anybody got any experience on welding/brazing/solder rods, or garden wire?

But if you twist the ends you've then got a bit too catch your hands on that sticks out and is sharp, that's why I'm a bit stuck.

Founds a place to tuck the twisted ends in!But if you twist the ends you've then got a bit too catch your hands on that sticks out and is sharp, that's why I'm a bit stuck.

Seriously, it would require some forethought to know where to stop and make it so the ends were less likely to catch on something. Maybe right under the head in the direction of the wrap or coiled up behind the handle under the poll.

yes I had considered.....I still haven't ruled it out. I've a 6 and 1/2 inch long piece of ash glued on the back now, ready to be shaped down. I'm still considering making a space to thread the wire right up through the eye though. might have to give that a try

Plowmaster

ArboristSite Member

Like H-ranch said... safty wire twist... a 90 degree bend at the end... drill a small hole ... stuff twist in and glue if needed... good luck with projectBut if you twist the ends you've then got a bit too catch your hands on that sticks out and is sharp, that's why I'm a bit stuck.

I like a leather wrap. Try a piece of foam hot water pipe insulation then wrap it tight with black electrical tape. You can replace it daily if you need to. Anything you put on it just screems, look, I can’t hit the same spot twice.

Similar threads

- Sticky

- Replies

- 0

- Views

- 2K

- Replies

- 41

- Views

- 2K