You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Case Bearing Installation

- Thread starter Mastermind

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Mastermind

Work Saw Specialist

Mastermind

Work Saw Specialist

How much will this trip to the dentist cost?

Mastermind

Work Saw Specialist

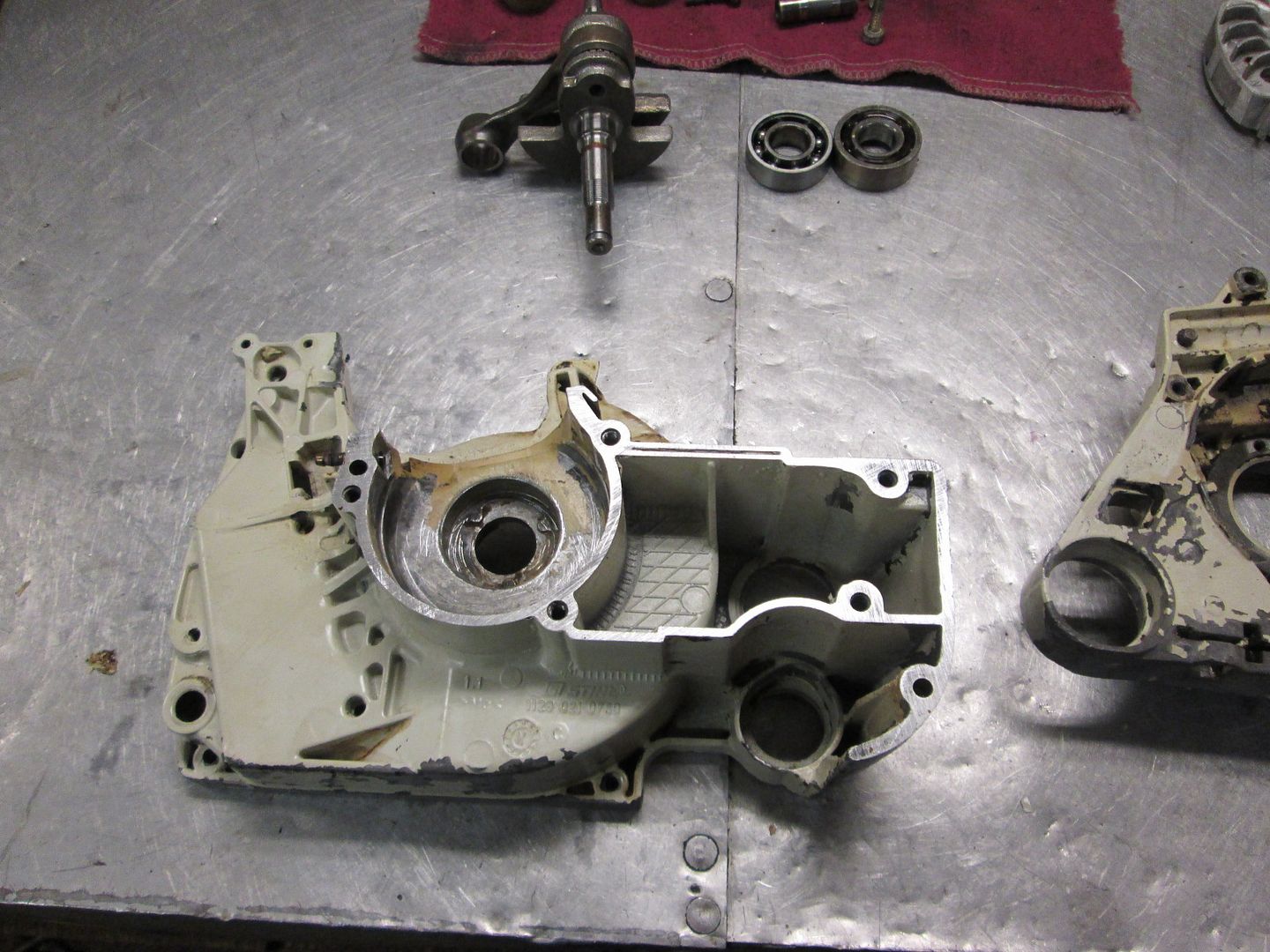

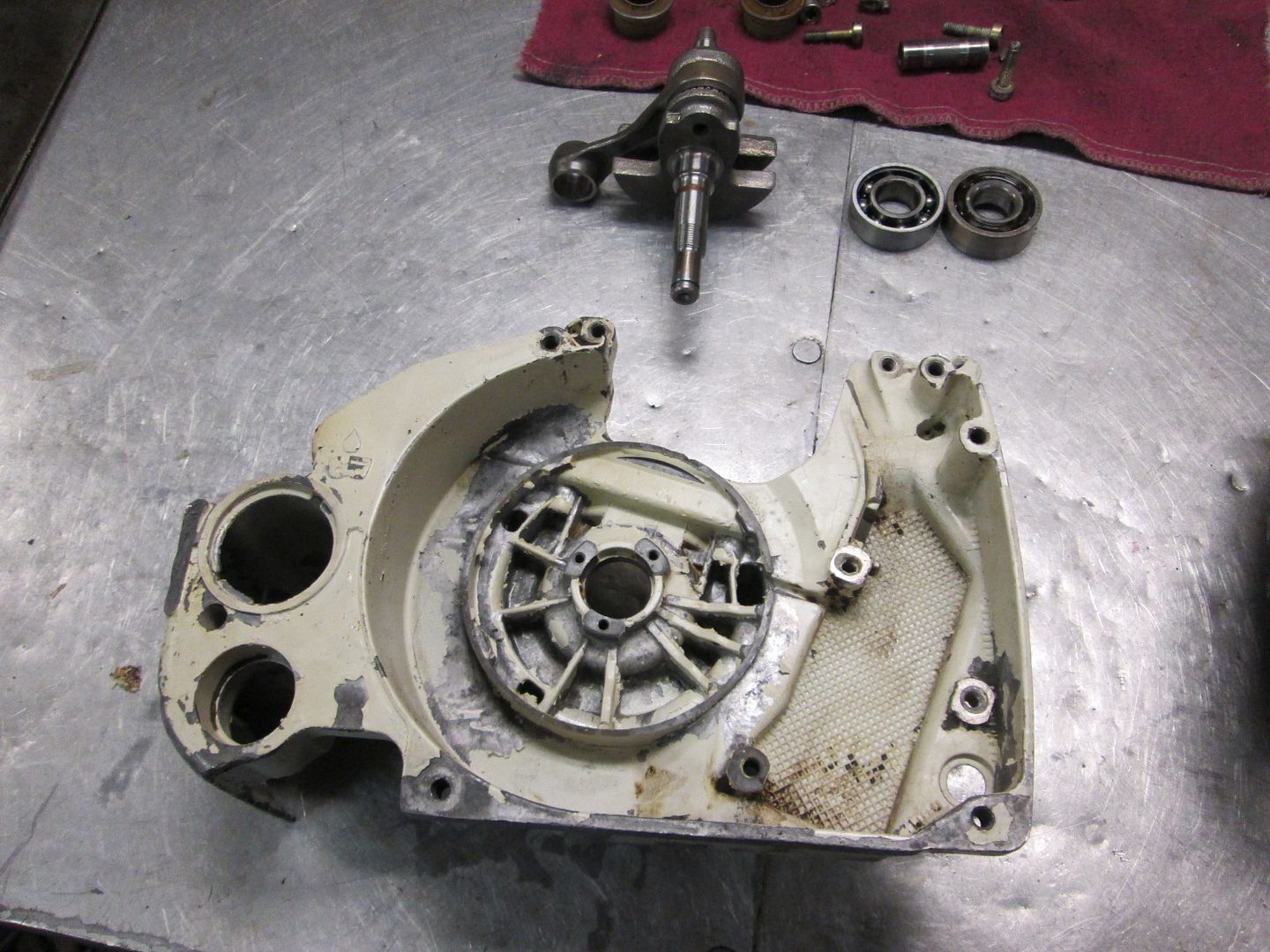

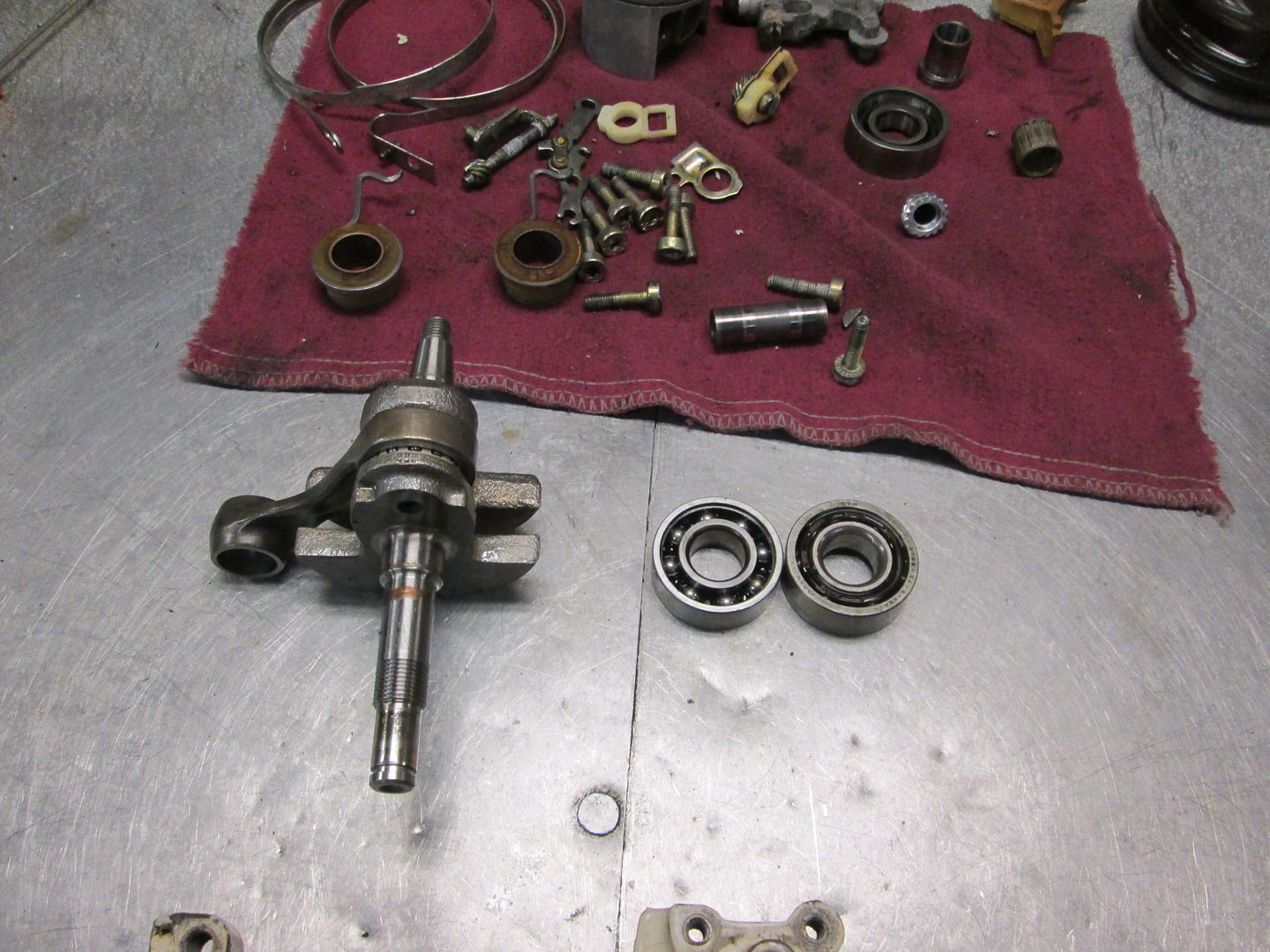

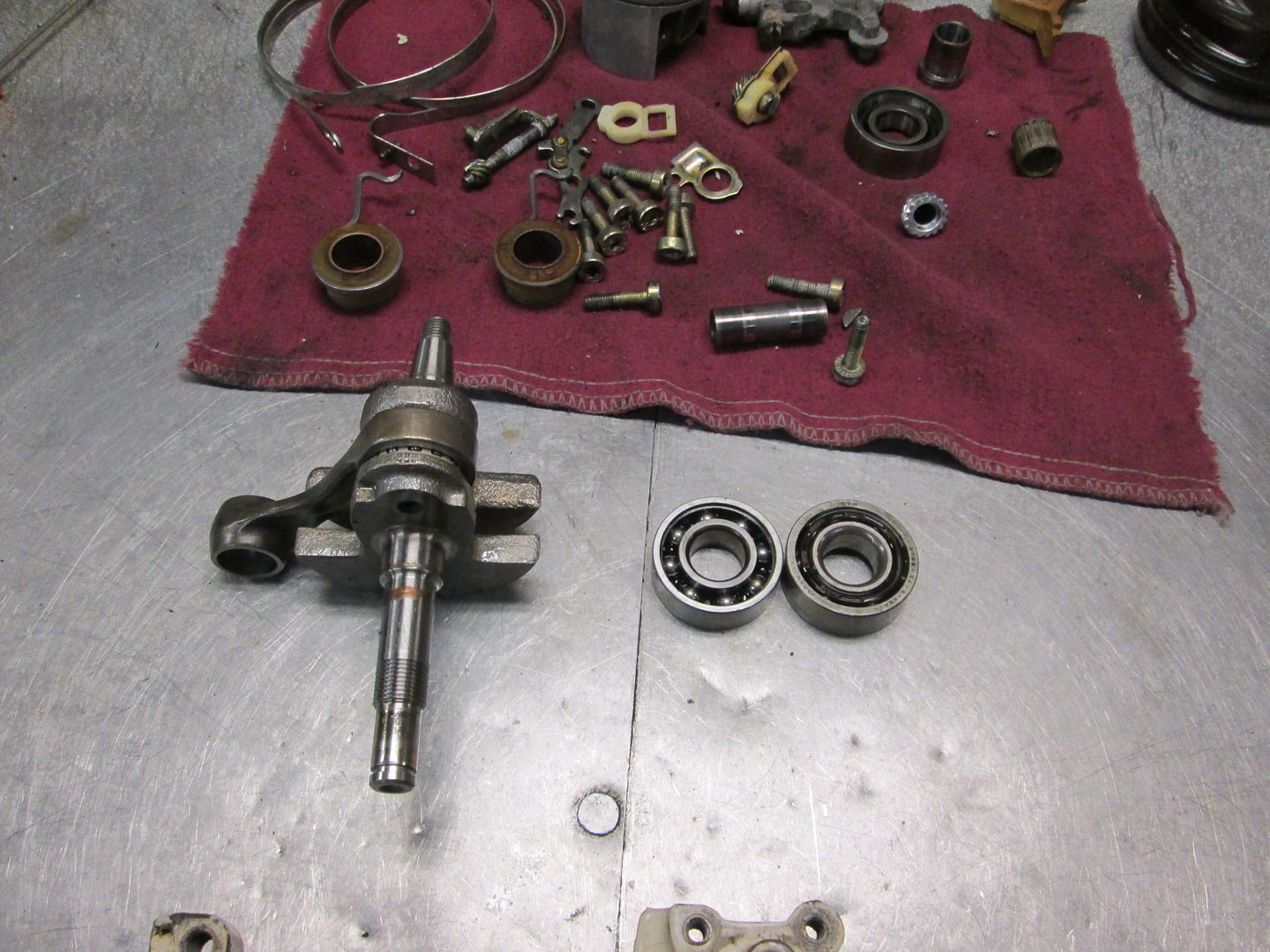

OK, now that all the parts are cleaned, inspected, and laid out, it's time to start reassembling.

Our local guy is hoping to use this saw as a backup for one that ain't quite this worn out. What we have done is clean all the parts, then checked the bearing cages for cracks, and the crank for wear. Believe it or not, these parts seem to be in good condition.

Our local guy is hoping to use this saw as a backup for one that ain't quite this worn out. What we have done is clean all the parts, then checked the bearing cages for cracks, and the crank for wear. Believe it or not, these parts seem to be in good condition.

Mastermind

Work Saw Specialist

How much will this trip to the dentist cost?

150.00

Trx250r180

Saw polisher

me likes the angled finned jug and the early flywheel ,it's just a diamond in the rough

sefh3

Addicted to ArboristSite

Are the cranks known to break or was it operator error?

Mastermind

Work Saw Specialist

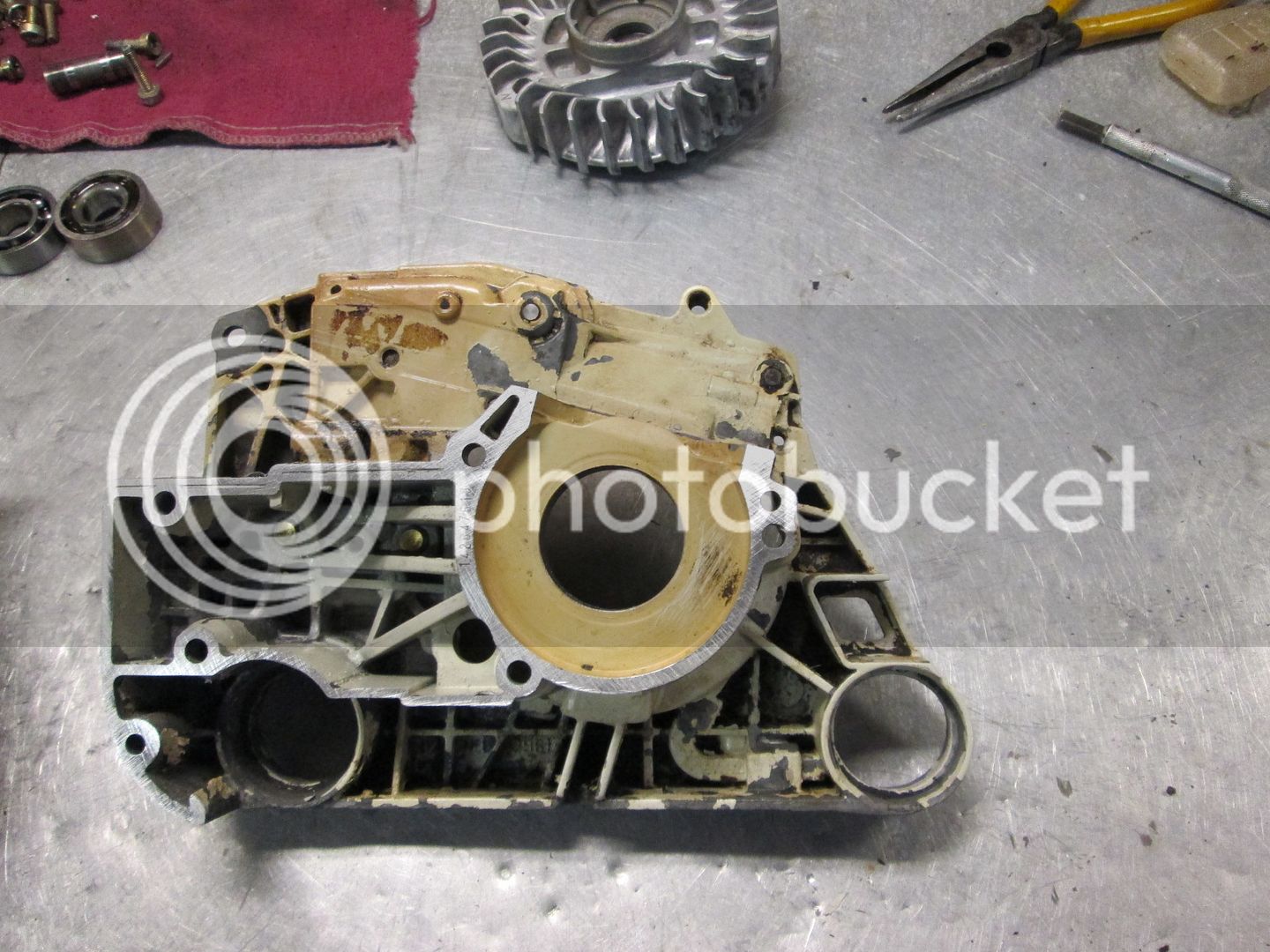

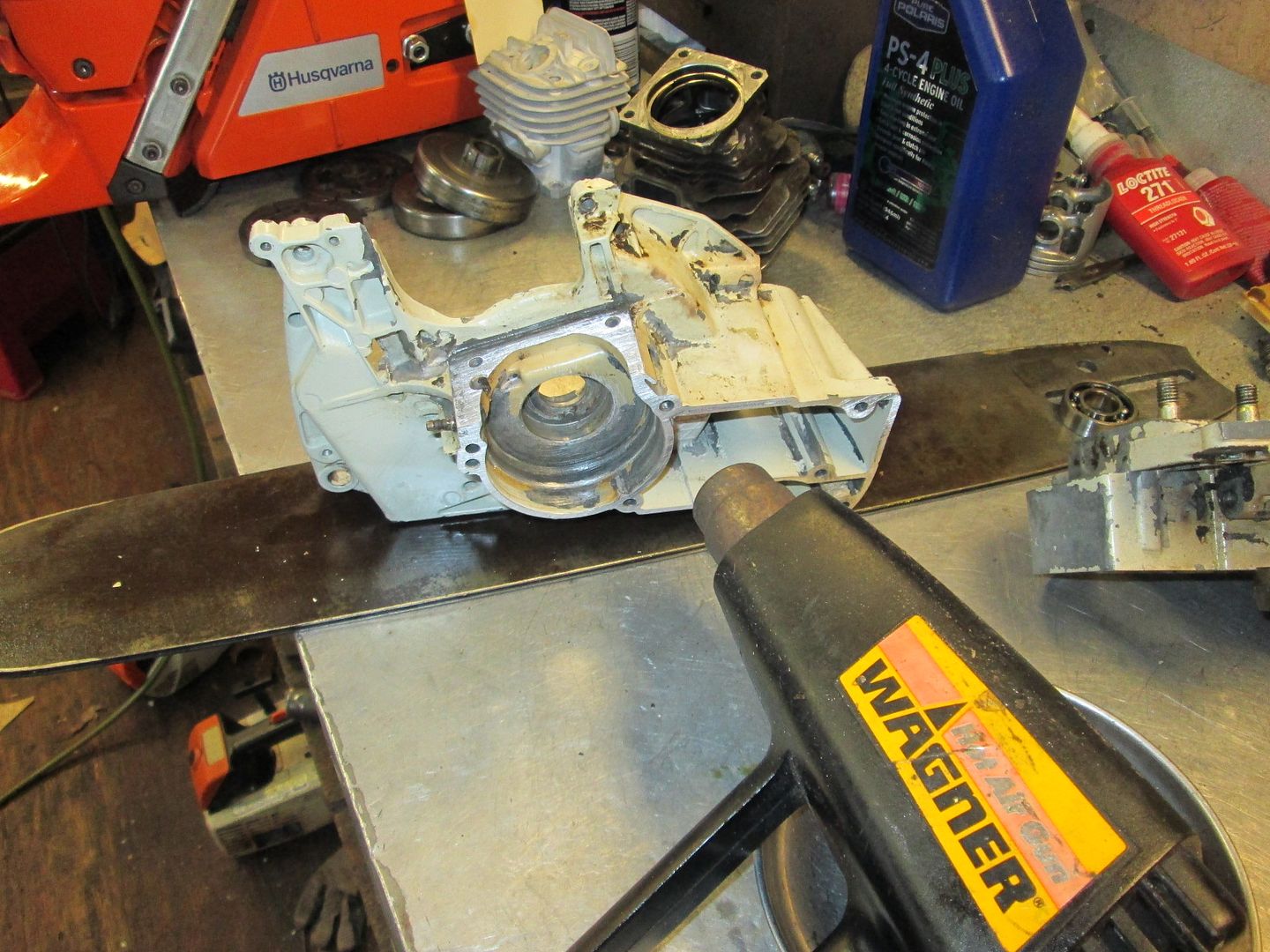

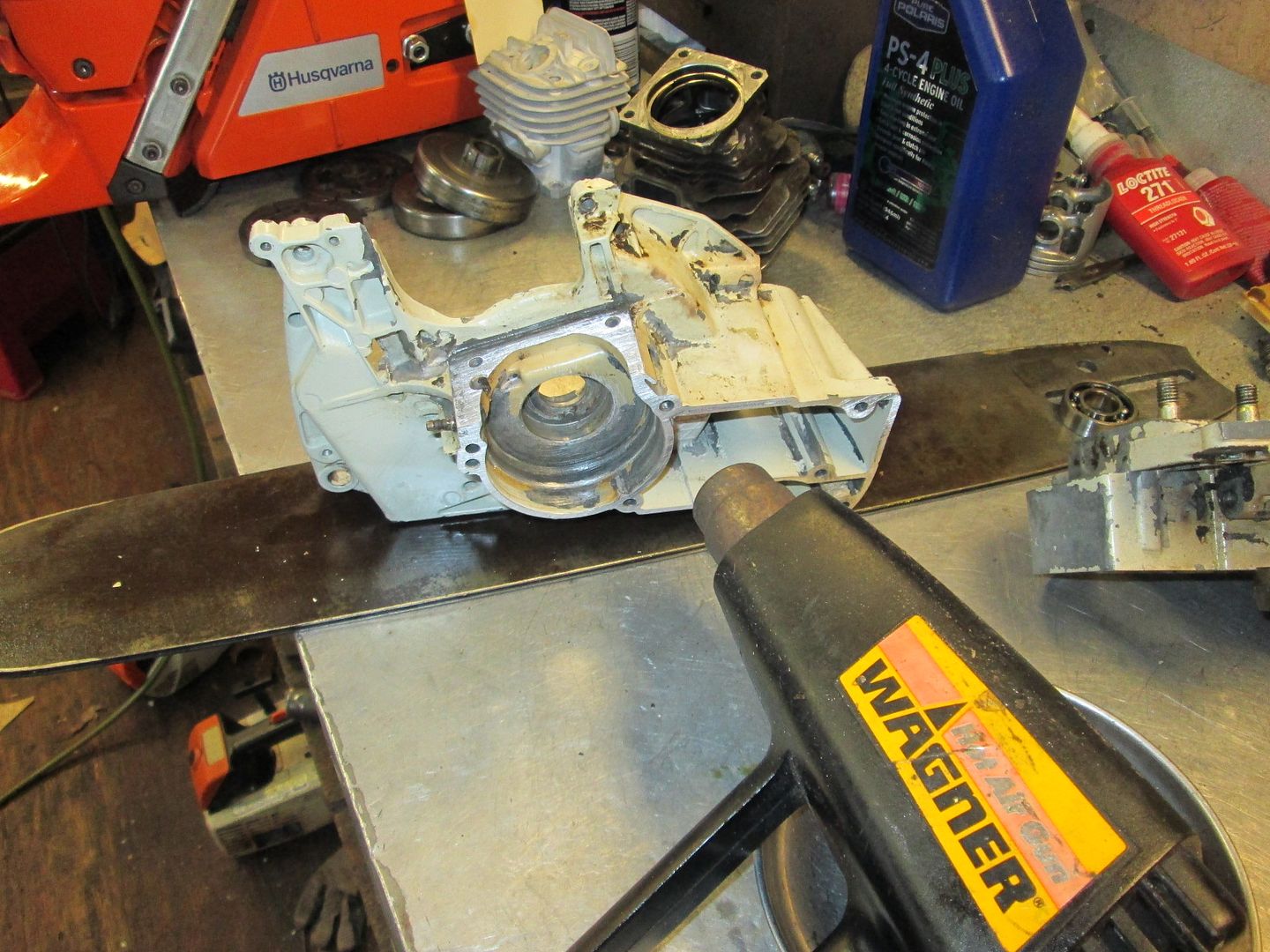

Now Jon is heating the PTO side at the bar pad first. He'll get it hot enough that the bearing will just drop in. How long you have to heat it, and how hot, is just something Jon has learned for doing a **** load of saws.

In this picture you can see that he's installed the oil pump on the case. This is actually a junk pump that he keeps just for this reason. The oil pump is used to locate the depth of the bearing in the bore. When the case half is hot enough, the bearing just slides in against it.

Like this.....

No hammering or pressing is needed.

In this picture you can see that he's installed the oil pump on the case. This is actually a junk pump that he keeps just for this reason. The oil pump is used to locate the depth of the bearing in the bore. When the case half is hot enough, the bearing just slides in against it.

Like this.....

No hammering or pressing is needed.

Mastermind

Work Saw Specialist

me likes the angled finned jug and the early flywheel ,it's just a diamond in the rough

Good eye my friend.....

I'm assuming it's an 046 or 066 your building? Are the cranks known to break or was it operator error?

The broken crank is from a 10mm 044. It probably had a million BF on the saw.

sefh3

Addicted to ArboristSite

I tried to edit that but I got caught up looking at your pictures. I see the cylinder in the first picture.

Mastermind

Work Saw Specialist

After a few minutes, the bearing will soak enough heat out of the case to allow the crankshaft to slide in. Again, no hammers, or special tools needed.

Now he heats the flywheel side....

While it is cooking, he got the gasket on the PTO side, and is ready for the flywheel side to just slide on. We use Loctite 518 here too. I hate leaks on anything......it's cheap insurance.

Making damn sure it's hot enough.

Drops the bearing....

After a few minutes, the heat from the case half soaks into the bearing, and the halves just slide together.

Now he heats the flywheel side....

While it is cooking, he got the gasket on the PTO side, and is ready for the flywheel side to just slide on. We use Loctite 518 here too. I hate leaks on anything......it's cheap insurance.

Making damn sure it's hot enough.

Drops the bearing....

After a few minutes, the heat from the case half soaks into the bearing, and the halves just slide together.

sefh3

Addicted to ArboristSite

Are you using both the loctite and the gasket? How does it compair to Dirko?

sunfish

Fish Head

Looks like you are makin chicken salad out of chicken ****!

Good work man!

Good work man!

supertrooper

ArboristSite Lurker

Outstanding! Looks much easier than the other ways I have seen it done. Gonna make my life easier when Im putting my 036 back together! You sir are very much appreciated!!

- Joined

- Nov 9, 2005

- Messages

- 1,539

- Reaction score

- 1,817

And who says you can't make a silk purse........

I can't believe someone would ask you to work on such a decrepit saw  .

.

Steve NW WI

Unwanted Riff Raff.

Nice write up Randy. I'm just curious the reason for heating indirectly, why not just point the heat gun at the bearing race?

If you'd care to, I bet a lot of guys would like an IR temp gun reading on the case when it's ready.

If you'd care to, I bet a lot of guys would like an IR temp gun reading on the case when it's ready.

nmurph

ArboristSite.com Sponsor

- Joined

- Nov 26, 2007

- Messages

- 16,162

- Reaction score

- 7,167

I use my stove (have used a heat gun a few times) set to 250°F. That temps seems to let the bearings on most saws drop right in. I used to use 225° and it would take a few taps with the soft-blow hammer to seat them.

Trx250r180

Saw polisher

Nice write up Randy. I'm just curious the reason for heating indirectly, why not just point the heat gun at the bearing race?

If you'd care to, I bet a lot of guys would like an IR temp gun reading on the case when it's ready.

for some reason Randy cant log on ,i just got an email from him

Similar threads

- Replies

- 4

- Views

- 839

- Replies

- 27

- Views

- 3K

- Replies

- 0

- Views

- 299