I recently serviced a Husky K760 chop saw that has a primer bulb with a small crack in it. The saw starts and runs fine without even using the primer bulb (choke three or four pulls until a pop and then one or two pulls with choke off). When warm, the saw starts on one pull with choke off.

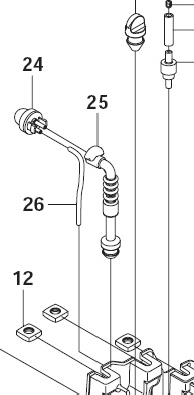

To replace the primer bulb on this saw requires considerable mechanical take down and potentially several hours of work to replace. That's a poor design, so I recommended running the saw as is because it starts about the same as all my Stihl chainsaws that have no primer bulb and it appears to run OK.

However, I've now been told that after running under load for awhile, the saw starts shooting fuel out the primer bulb and it loses most if its power. Is that true? Seems goofy to me, so I thought I'd ask the Forum for another opinion. Anybody else encounter this?

Please advise and TIA.

To replace the primer bulb on this saw requires considerable mechanical take down and potentially several hours of work to replace. That's a poor design, so I recommended running the saw as is because it starts about the same as all my Stihl chainsaws that have no primer bulb and it appears to run OK.

However, I've now been told that after running under load for awhile, the saw starts shooting fuel out the primer bulb and it loses most if its power. Is that true? Seems goofy to me, so I thought I'd ask the Forum for another opinion. Anybody else encounter this?

Please advise and TIA.