Torquin

ArboristSite Operative

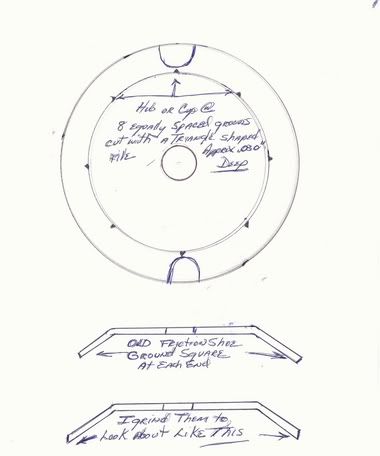

I picked up an old David Bradley the other day. It supposedly runs fine, except the starter cup is worn out. This is the cup the bolts to the flywheel, that the starter "wings" grip when they fly out as the cord is pulled. Does anyone know where I might find one of these?

It seems like it's similar to what came on the old Tecumsehs, but I don't even know where to get one of those at this point.

Thanks,

Chris

It seems like it's similar to what came on the old Tecumsehs, but I don't even know where to get one of those at this point.

Thanks,

Chris