breymeyerfam

Addicted to ArboristSite

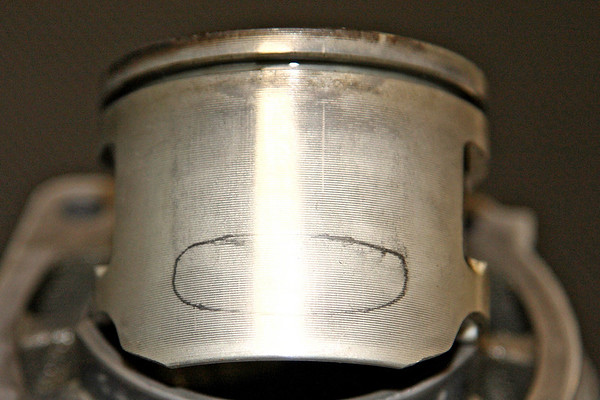

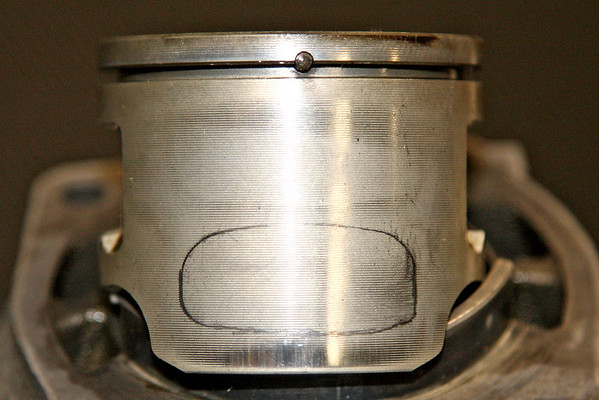

this afternoon was disassembly and everthing looks great. squish without gasket is between .020-.021. only thing holding me back is a carbide burr bit (.125 shaft and roughly .250 cutter with radiused nose). any suggestion to where to get one retail without having to order online? anyway here is some pics. the plan is just widening the exhaust and intake ports and running without a base gasket. while im at it, i see most say to use yamabond, but where do I get it, and which compund do I use? is there a comparable permatex or loctite product?