As I said before, just when you think you are pretty good, along comes someone even better.

Gypo's post and picture show just how far he's come since that goofy hook picture of his I used to illustrate too much hook.

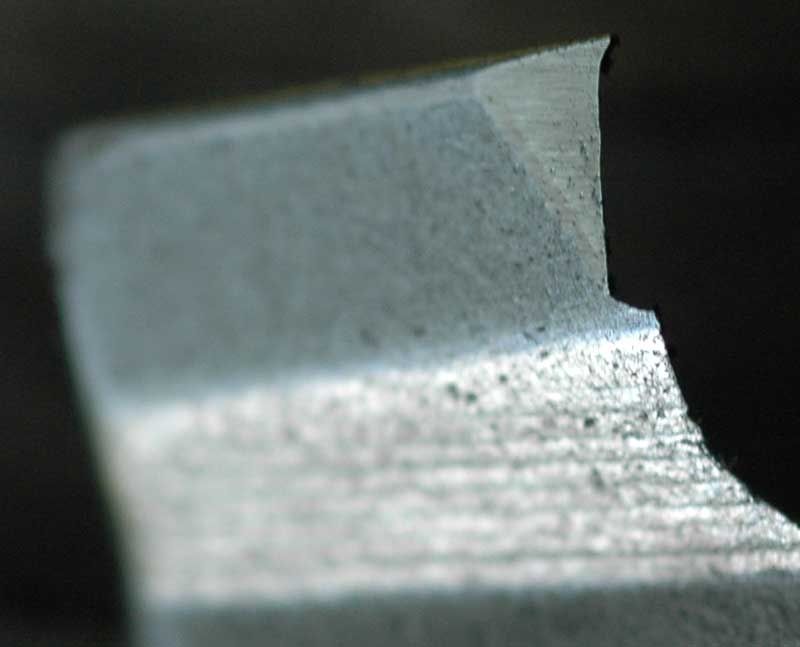

My only contention with his post, is his definition of the working corner. When I think of a corner, it is just that, the point. He includes the entire top portion of the side plate in his definition of the corner. I'm no expert on definitions, or proper chain nomenclature, but by combining the side plate to the working corner, it limits detailed discussion of the side plate.

Gypo argued eloquently over at GF, the working corner does most of the work. In this post I argue the side plate does, not the top plate. Hence only half the working corner.