Jan-Sietze

ArboristSite Operative

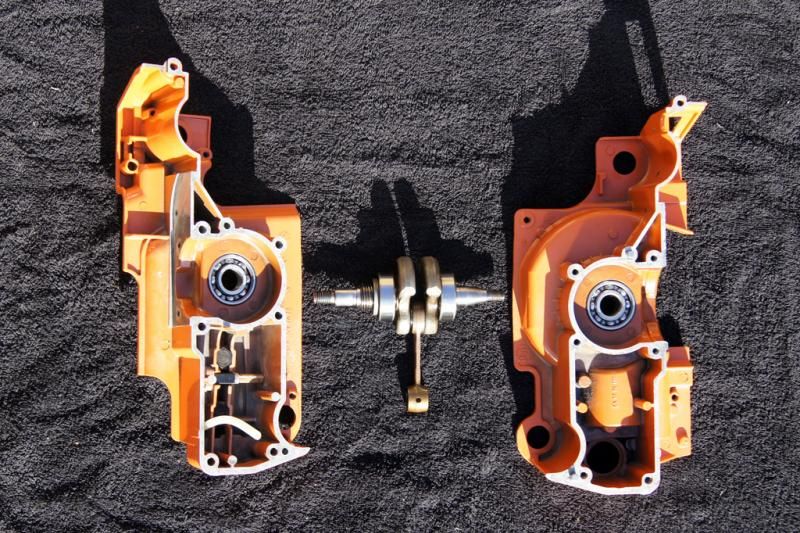

I received my new crankshaft,

okay it's a used one but in good condition.

Yesterday I split crankcase and have it nicely cleaned.

Now my question:

How do I replace the crankshaft without destroying the new crankshaft and bearings ?

What should I do; get rid of old crankshaftbearings and use the original 55 ones (which is not very good anymore).

Or slap the old bearings from the crankcase and push the new crankshaft whit bearings and all in the crankcase ?

(You understand me?)

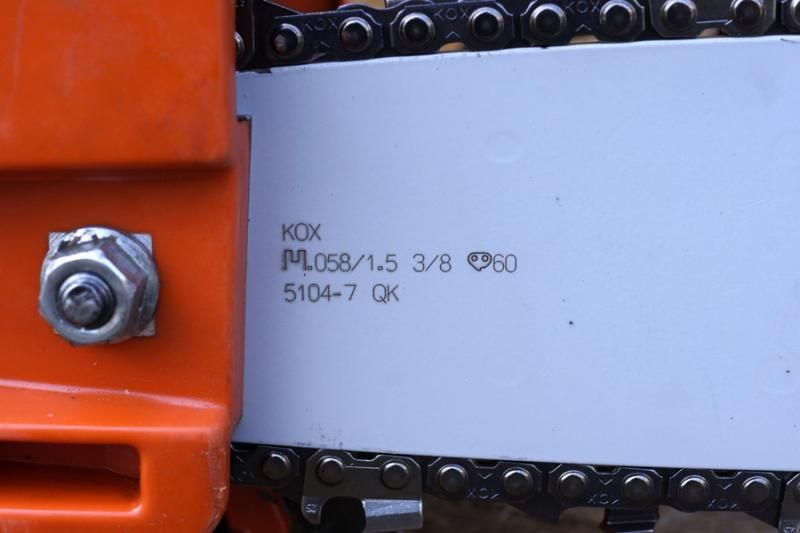

A few pictures

Thanks !

With kind regards

okay it's a used one but in good condition.

Yesterday I split crankcase and have it nicely cleaned.

Now my question:

How do I replace the crankshaft without destroying the new crankshaft and bearings ?

What should I do; get rid of old crankshaftbearings and use the original 55 ones (which is not very good anymore).

Or slap the old bearings from the crankcase and push the new crankshaft whit bearings and all in the crankcase ?

(You understand me?)

A few pictures

Thanks !

With kind regards

:msp_thumbup:

:msp_thumbup: