XPLRN

Dad ^^^^ wouldn't understand the CAD!!! :-)

Last year I got a really nice low usage white top Rancher 50. I'm finally getting around to finding out what the saw is all about as the original owner had told me that it had some kind of carb issue as it would fire but not run.

Recently I had two pieces of equipment that didn't want to start with the wet plug/wet cylinder syndrome. Tore them apart, found the hardened up metering diaphragms, replaced them and they ran just like they should. Figured since this Rancher 50 was known to have a carb issue I'd be able to easily get it up and running by doing the same thing..............not there yet.

The things I've done to this saw;

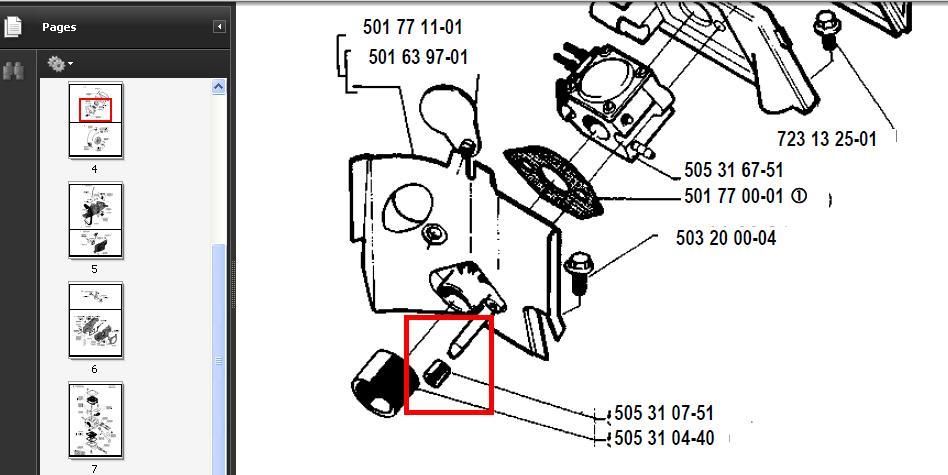

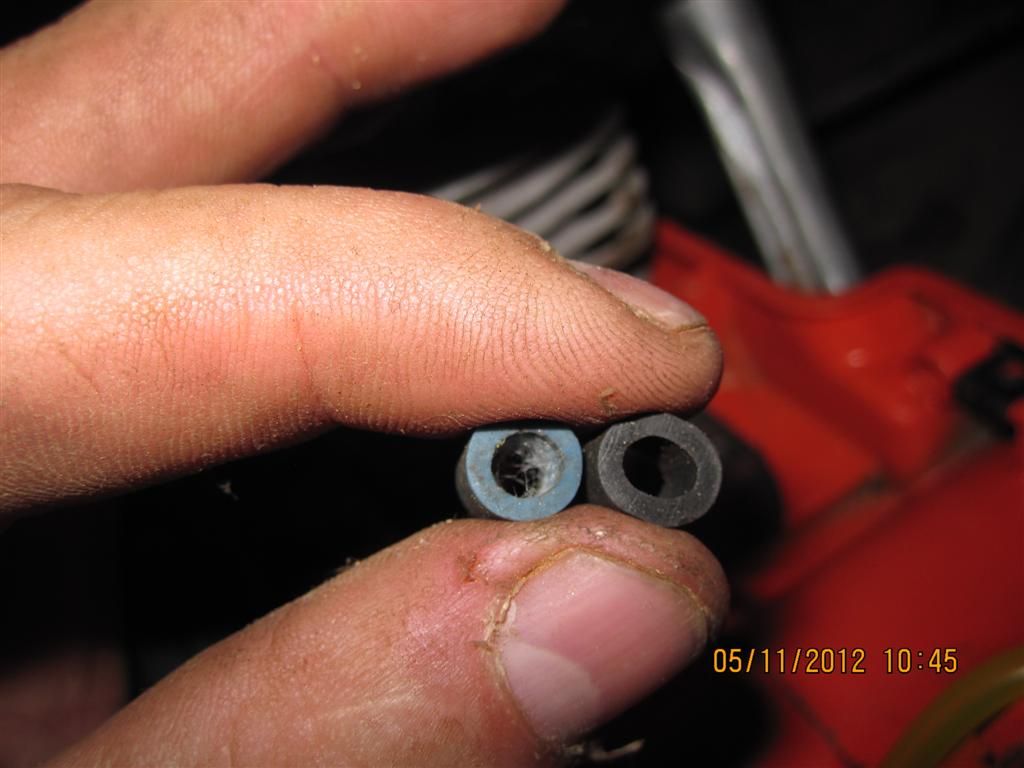

1. New fuel line(used the filter that was in it) and took the tank vent out to check it (seems to be clean)

2. Installed carb kit........however the diaphragms in the carb seemed to be fine

Now after doing those things I can prime the carb and it will fire and run...........till the fuel is consumed. Once it actually ran on for about 4-6 seconds...surging at mid-range RPM's. It always dies when opening the throttle.

I did a fair amount of searching/researching on the AS archives and found this thread where someone had all the components needed to make a running engine( spark, gas, compression) ;

http://www.arboristsite.com/chainsaw/180749.htm

Since I've been thru the diaphragms issue with the other two pieces of equipment I KNOW about the flooding out issue. This one is different in that it will always start and run for a burst with the fuel primed in the carb. I don't have the tools to check for bad crank seals but am wondering if there might be something I missed in the carb assembly on this one!??? Thought I'd gotten it down on the other two..........however they were known runners before the deterioration of the diaphragms.

I've also taken the nylon interface plate off and checked the flexible rubber sleeve that attaches the interface plate to the cylinder. Everything looks good there.....the rubber sleeve is stretchy with not cracks or signs of hardening.

Nothing to do with the carb issue/non-running issue but I did a light muffler mod on it and the P/C looks great and the saw has great compression.

I am going to buy a new spark plug for it when I get into town next but since it does start and run briefly I'm not soo suspect of that being the issue!?? Looks like I'll be removing the carb,, taking it apart, blowing thru all the orifices and looking for something obviously wrong in the assembly process............it was late and who knows!!??? I would appreciate your suggestions as it just seems to be something real simple I'm missing!!??

Recently I had two pieces of equipment that didn't want to start with the wet plug/wet cylinder syndrome. Tore them apart, found the hardened up metering diaphragms, replaced them and they ran just like they should. Figured since this Rancher 50 was known to have a carb issue I'd be able to easily get it up and running by doing the same thing..............not there yet.

The things I've done to this saw;

1. New fuel line(used the filter that was in it) and took the tank vent out to check it (seems to be clean)

2. Installed carb kit........however the diaphragms in the carb seemed to be fine

Now after doing those things I can prime the carb and it will fire and run...........till the fuel is consumed. Once it actually ran on for about 4-6 seconds...surging at mid-range RPM's. It always dies when opening the throttle.

I did a fair amount of searching/researching on the AS archives and found this thread where someone had all the components needed to make a running engine( spark, gas, compression) ;

http://www.arboristsite.com/chainsaw/180749.htm

Since I've been thru the diaphragms issue with the other two pieces of equipment I KNOW about the flooding out issue. This one is different in that it will always start and run for a burst with the fuel primed in the carb. I don't have the tools to check for bad crank seals but am wondering if there might be something I missed in the carb assembly on this one!??? Thought I'd gotten it down on the other two..........however they were known runners before the deterioration of the diaphragms.

I've also taken the nylon interface plate off and checked the flexible rubber sleeve that attaches the interface plate to the cylinder. Everything looks good there.....the rubber sleeve is stretchy with not cracks or signs of hardening.

Nothing to do with the carb issue/non-running issue but I did a light muffler mod on it and the P/C looks great and the saw has great compression.

I am going to buy a new spark plug for it when I get into town next but since it does start and run briefly I'm not soo suspect of that being the issue!?? Looks like I'll be removing the carb,, taking it apart, blowing thru all the orifices and looking for something obviously wrong in the assembly process............it was late and who knows!!??? I would appreciate your suggestions as it just seems to be something real simple I'm missing!!??

Last edited: