Well got the 350 under my belt, now to try something "pro grade"

Saw came from auction no known history. Started right up cut oiled good. 150 comp

Going to swap this out.. Though it would have been unlimited being a 99

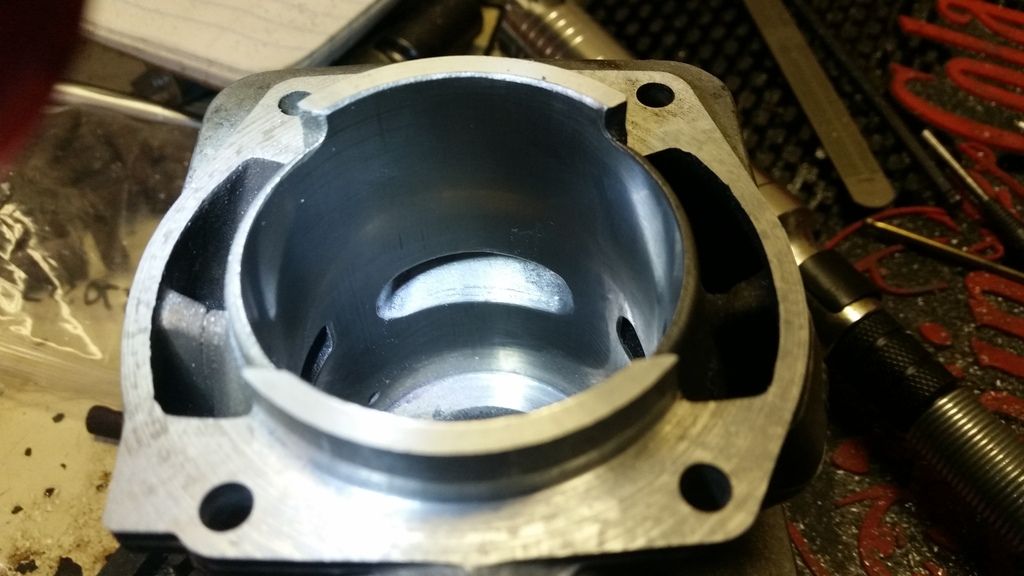

Intake side of the piston (notice no locating pin)

Exhaust side, found the pin.... Really surprised it didn't catch.

I think the original piston lost the locating pin and someone swapped in a new one backwards. You can see a few contact marks in the squish

Checked the numbers with a gasket. over .032 squish

In, 74 Ex, 99 Tr, 121

Made all the goodies for the 50 mm jug today,

Alum is to cut the squish band, wood is to sand the band, and white plastic is to cut the base.

cut .035 from the base, going to set squish at .020-.022. Intake should end up round 78/79, going to set exhaust 100 transfers 120, saw is going to wear a 24" bar

Thoughts and opinions welcome

Saw came from auction no known history. Started right up cut oiled good. 150 comp

Going to swap this out.. Though it would have been unlimited being a 99

Intake side of the piston (notice no locating pin)

Exhaust side, found the pin.... Really surprised it didn't catch.

I think the original piston lost the locating pin and someone swapped in a new one backwards. You can see a few contact marks in the squish

Checked the numbers with a gasket. over .032 squish

In, 74 Ex, 99 Tr, 121

Made all the goodies for the 50 mm jug today,

Alum is to cut the squish band, wood is to sand the band, and white plastic is to cut the base.

cut .035 from the base, going to set squish at .020-.022. Intake should end up round 78/79, going to set exhaust 100 transfers 120, saw is going to wear a 24" bar

Thoughts and opinions welcome