trappermike

ArboristSite Guru

You usually won't hear detonation in a 2-stroke,but if the ignition is too advanced you may find the piston crown melted,or signs of extreme heat and/or aluminum residue on the spark plug.

Here's how I advance the timing. I put the degree wheel on, find TDC w/the flywheel on, mark TDC with a fineline marker on the F/W & correspondingly on the side of the jug. I advance the crank the amount I want then mark that location in line with the TDC mark from the F/W. I pull the flywheel (with the degree wheel still on), turn the motor back to TDC (degree wheel), reinstall F/W rotating it to my advance mark. I put a tiny dab of super fine polishing paste (toothpaste will work), to lock on the F/wheel. You can double check that things haven't moved by cross referencing the degree wheel to your marker lines.

Steve

A part of what led me to the issue of timing was noticing that unlike my 064 or old 066, a half-*ss pull on my 046 will result with a violent removal of the starter handle from my hand. So I am in the process of replacing the 064 alloy flywheel with an 046 poly flywheel. As near as I can tell, this advances the timing by at least one half the width of the woodruff to maybe the full width. This is more than I can correct by moving the coil, so I'm working on modifying/relocating the key. I've got the flywheel on, and the saw is running; however I'm concerned with detonation and top end damage under load. I've heard detonation in a V8, what will it sound like in a chainsaw? I'm running premium fuel so I should have the ability to run more advance without detonation.

A part of what led me to the issue of timing was noticing that unlike my 064 or old 066, a half-*ss pull on my 046 will result with a violent removal of the starter handle from my hand. So I am in the process of replacing the 064 alloy flywheel with an 046 poly flywheel. As near as I can tell, this advances the timing by at least one half the width of the woodruff to maybe the full width. This is more than I can correct by moving the coil, so I'm working on modifying/relocating the key. I've got the flywheel on, and the saw is running; however I'm concerned with detonation and top end damage under load. I've heard detonation in a V8, what will it sound like in a chainsaw? I'm running premium fuel so I should have the ability to run more advance without detonation.

U saying you used an 046 poly flywheel on an 064? Thats a new one on me....

U saying you used an 046 poly flywheel on an 064? Thats a new one on me....

I'm working on it. The taper on the 064 crank is the same as the 046 (460?) Poly flywheel I've got. The key location doesn't match, and there is a lip on the case side of the flywheel that I had to remove in order to clear the 064 case. The saw ran, but I need to correct the timing

I opened my mouth...I guess it's time for my first thread...bare with me, I've gotta figure out how and get pics of the procedure...What about the starter issue? The starter cup on the 046 flywheel is too small for the rope rotor and starter pawls on the 064 starter. Did you modify the 046 rope rotor and then put it into the 064 starter housing? There's a lot of monkeying around needed to get a working starter with that set-up.

Like I said, I mocked it up but the starter issues kept me from following through.

As for timing lights I think that whatever one works for you is the right one,if your own doesn't work well try a couple of buddy's lights to see if they work better. Probably a Snap-on light will work well if you can afford one. I find that the timing light's pickup sensor that attaches to the plug wire is the key,some work better than others. The timing light I use now wasn't expensive,a cheapy actually, but works fine,others had trouble "picking up" the spark signal.

On another note,I once tried using "Surface Gap" spark plugs,but I found that since saws don't have actual CDI ignition they didn't have the power to fire them,the saw would idle ok but would misfire badly as soon as I revved it up. But I find that the "Fine wire" type race plugs,Platinum,palladium etc. by NGK,Bosch etc. work well. I would be interested to test the "Triple Fire" type plugs if I could find one with the correct reach and heat range,but I'm not sure saw ignitions have enough power to fire them well. Has anyone tried them?

You are right. Combustion chamber style and rpm are goverining factors in ignition advance. There is at least one more important factor: cylinder filling (i.e. volumetric efficiency).

Either in 4-stroke or 2-stroke engines required ignition advance is reduced when cylinder filling is increased.

In 4-stroke engines this is evident by looking at turbocharged engine's ignition advance tables when the engine is on turbocharger boost. Ignition advance gets reduced by about 15 degrees when turbocharges comes into play.

In 2-strokes we have the same "turbocharger" effect through tuned pipe.

Stock saws have only simple exhaust muffler box which has zero effect in elevated cylinder filling. I believe manufacturers have engineered ignition advance to max out power delivery with this combo.

Slap on tuned pipe on such saw, and I believe our stock ignition timing is holding back our saw. More power can be had by retarding the ignition event.

What stock timing does, is to ignite combustible mixture far too soon, and pressure peak exists too soon, where crankshaft is not yet in it's most ideal position (at about 17 degrees past TDC).

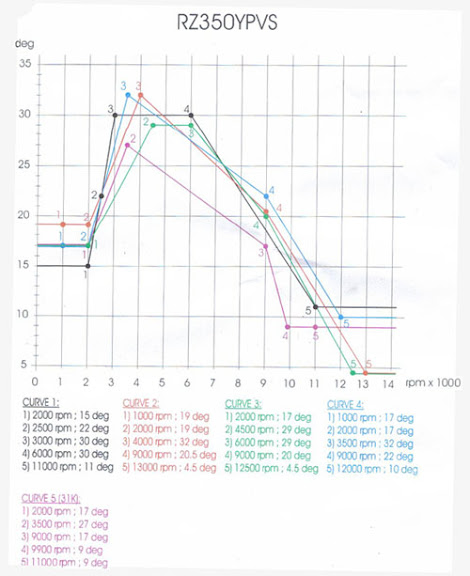

Please have a look at enclosed Yamaha 2-stroke motorcycle engine ignition advance curves. By my wild guess, the tuned pipe seems to come on at about 11 000rpm and finishing at about 14 000rpm. Have a look at ignition advance requirements what the tuned pipe does to the engine.

Ignition advance requirements are way different at lower rpm's when the engine is not "on the pipe".

There are many different ignition curves. I believe that this is a comparison between different available Yamaha ignition boxes, suited for different combos of tuned pipes and differently ported cylinders.

I believe many piped saws would benefit from retarding the ignition sensor by say 5 degrees (or perhaps even more).

Enter your email address to join: