Artsi_L

New Member

Hello

I've read this forum on saw modding. Many threads revolve around cylinder porting and tuned exhaust pipes.

The little understanding I've accumulated on 2-stroke engine tuning points towards taking into account factor of fine tuning of spark ignition event.

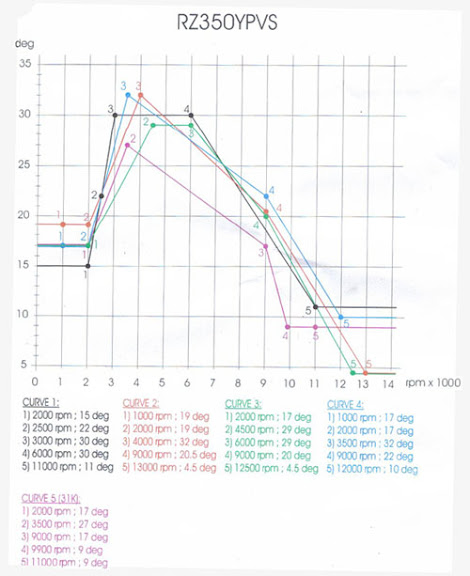

As tuned exhaust pipe elevates cylinder's volumetric efficienfy, needed spark advance should decrease. In other words, we'd need to retard spark advance where the engine is happy.

I fear some modded saws out there with stock ignition timing are "knock limited" as it comes to power/torque delivery.

I am yet to check my saw's stock ignition advance, but I reckon it'll be more than 2-stroke motorcycle engines with tuned pipes.

Comments please.

I've read this forum on saw modding. Many threads revolve around cylinder porting and tuned exhaust pipes.

The little understanding I've accumulated on 2-stroke engine tuning points towards taking into account factor of fine tuning of spark ignition event.

As tuned exhaust pipe elevates cylinder's volumetric efficienfy, needed spark advance should decrease. In other words, we'd need to retard spark advance where the engine is happy.

I fear some modded saws out there with stock ignition timing are "knock limited" as it comes to power/torque delivery.

I am yet to check my saw's stock ignition advance, but I reckon it'll be more than 2-stroke motorcycle engines with tuned pipes.

Comments please.