By pressure I mean vacuum and pressure test. I note you only did the vacuum test.

Manual says 7.25 psi pressure and 4.25 psi on the vacuum.

Manual says 7.25 psi pressure and 4.25 psi on the vacuum.

By pressure I mean vacuum and pressure test. I note you only did the vacuum test.

Manual says 7.25 psi pressure and 4.25 psi on the vacuum.

According to the suggestions in Four Paw's thread, if the saws passes the vacuum test, it's good to go. But if it fails the vacuum test, then a positive pressure test can be used to pinpoint the leak, by the sound of hissing air, or by squirting soapy water on the seals and looking for bubbles.

That does not sound right. On 16" boards you shouldn't need to baby it. Can you post some pics of your chain?I did have to baby the feed at times, even on 16" boards.

If the saw had more power, then yes, it would cut faster, because I could feed it faster without bogging. Plus, it would be easier to operate because I wouldn't have to "baby" the feed.

That is very unlikely. Assuming everything else is good if the saw is bogging down easily sounds like you've lost torque. what's your WOT RPM and nominal cutting RPM? Sorry to harp on this but did you check the crankcase for positive pressure?Is the low compression because the rings are not sealing well, or because the combustion chamber is too large ?

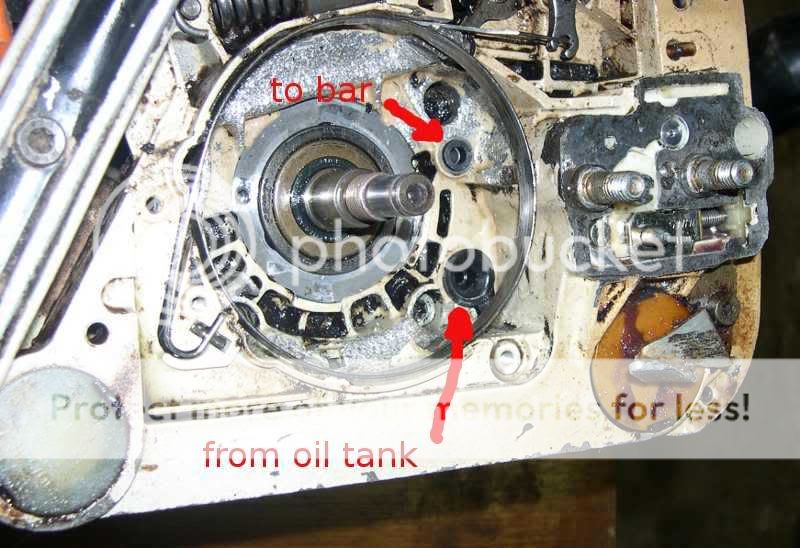

ExcellentThe good news is the JB'd oiler seems to be working fine.

That's one positive.Other good news is the modified air filter setup seems to be sealing perfectly. Here is the filter after the 10 or so tanks of gas.

That does not sound right. On 16" boards you shouldn't need to baby it. Can you post some pics of your chain?

Unless you UP the chain speed (change sprocket or increase RPM) or drop the rakers the chain is already often cutting as much as it can, pushing won't help, the chain is biting as much as it can and all pushing does is bog the saw.

Exactly. Torque has a lot to do with compression.Assuming everything else is good if the saw is bogging down easily sounds like you've lost torque

I'm afraid Santa hasn't left a tach in my stocking yet.what's your WOT RPM and nominal cutting RPM?

No reason to, as discussed before. Vac test was good, tune is slightly rich if you believe my ear, plug was very dark, carbon build up on piston top/exhaust port is significant, sides of piston/cylinder are wet and oily, idle is steady. All indications are that it is running slightly rich. What reason do you have to suspect an air leak ? I can't think of any.Sorry to harp on this but did you check the crankcase for positive pressure?

Enter your email address to join: