OH_Varmntr

Burner of stored sunlight

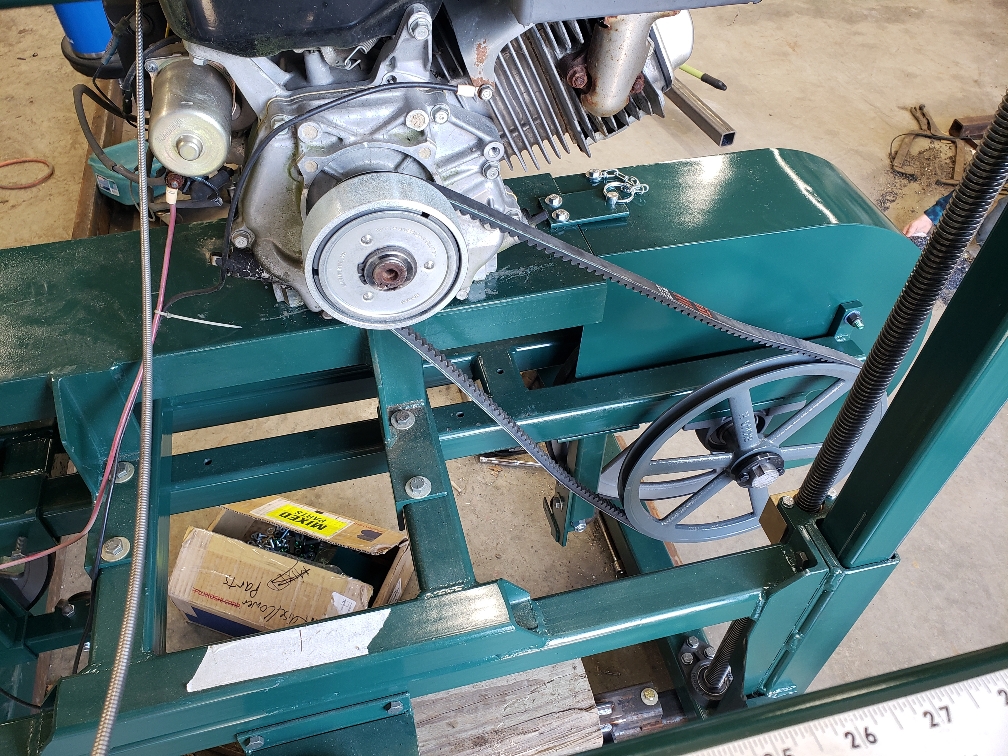

Lots of progress today, I'll upload another video tonight.

Sneek peek...

Sent from my SM-G960U using Tapatalk

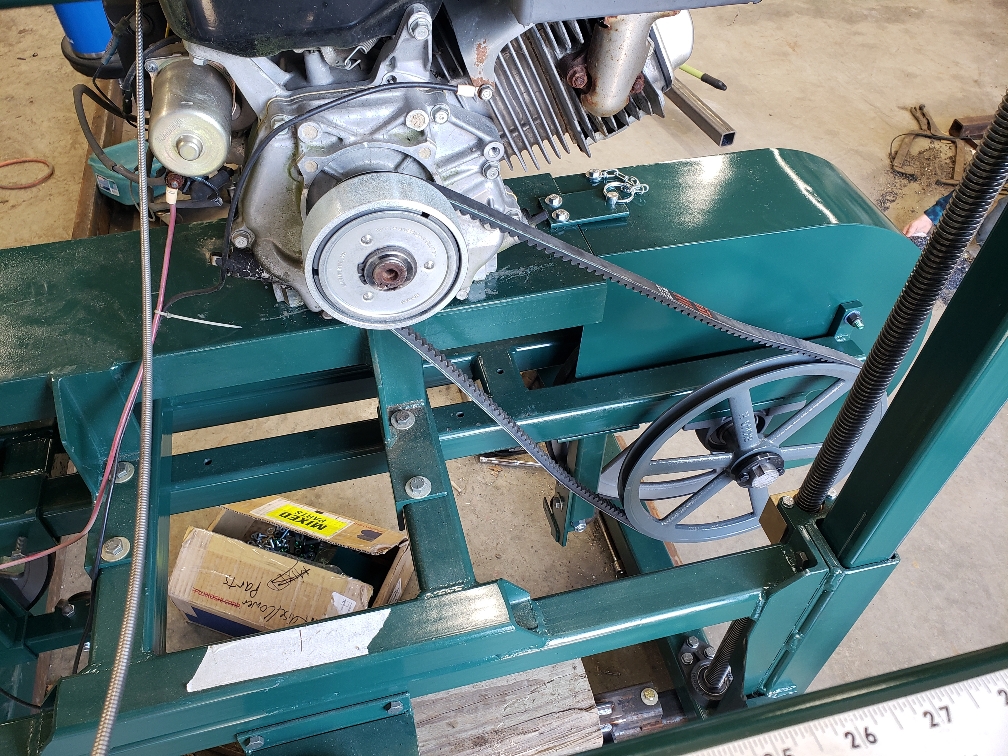

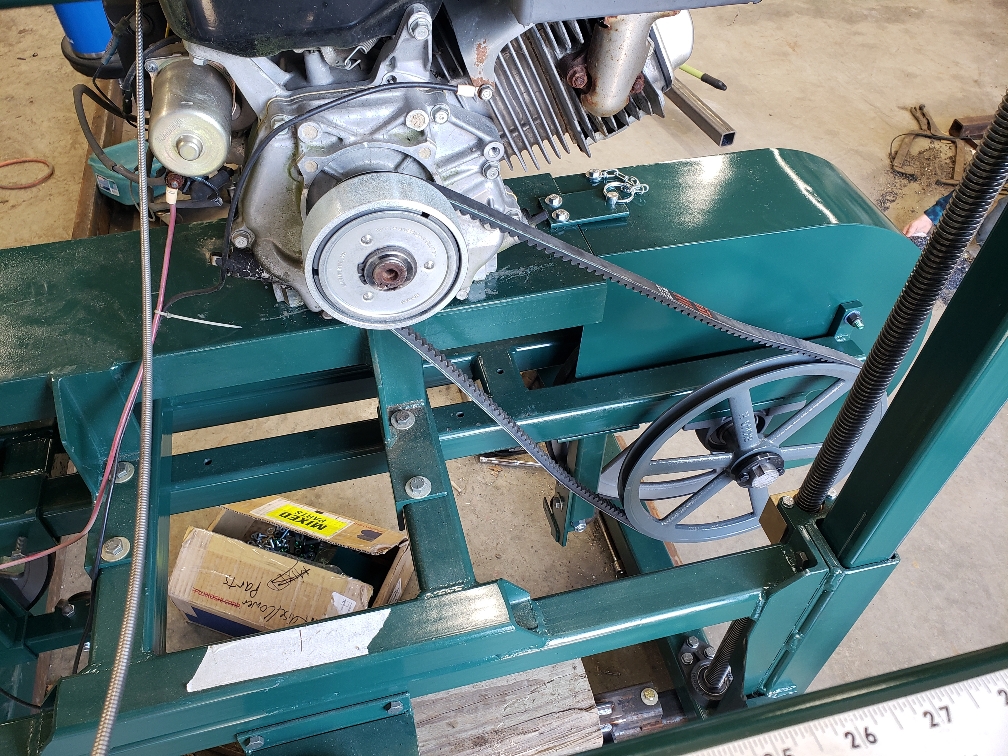

Sneek peek...

Sent from my SM-G960U using Tapatalk

I've thought about adding one. It would lessen the intervals between belt tensioning. Wouldn't take much.I am surprised there is not a spring loaded "idler" pulley on that drive belt.

The idler pulley does several good things,, besides keeping the belt flap to a minimum,,,

(more wrap around the pulleys,, etc,,)

Thank you, I hope it cuts as good as it looks!Your Work is excellent, Looking very good!

What are the dimensions on your carriage wheels? (Probably to big for a belsaw)Some progress this evening. The crossmembers for the track are welded up. These will receive 2 drilled and tapped holes. One on either end of the top to bolt the bunks down to. There will be spacers to hold the bunks up off the crossmembers to allow space for the log holders to slide. Only the center 4 will have them.

I began assembling the carriage but the paint isn't as cured as I'd like it to be so it will cure atleast one more night.

Also, the kit came with split lock washers. These will all be getting replaced with knurled safety lock washers.

Sent from my SM-G960U using Tapatalk

The bandwheels or the wheels the carriage rolls on the track?What are the dimensions on your carriage wheels? (Probably to big for a belsaw)

I pull one pin and they slide off.Terrific job - looks totally pro!

I just noticed your mill doesn't have the" batwing" wheel guard door openings.

Does this mean you have to completely remove the guards off to replace a blade etc?View attachment 974206

Carriage wheels. 2 or 3" diameterThe bandwheels or the wheels the carriage rolls on the track?

Sent from my SM-G960U using Tapatalk

Carriage wheels. 2 or 3" diameter

What's difficult??Being installed the way they are it's difficult to get you an accurate reading.

Sent from my SM-G960U using Tapatalk

TRTermite, seems to be totally oblivious to the "Fact" that he could go directly to Linn Lumbers web site and ask the question there of the fine people of Linn Lumber. "You can not teach someone anything, You can only help them discover it from within"

I Thank You For The picture . I would think some of the M14 sawmill owners would appreciate this option for their carriage issues. Your thread / project is moving right along. NICE WELDS too

Parts came in for my idler setup.I am surprised there is not a spring loaded "idler" pulley on that drive belt.

The idler pulley does several good things,, besides keeping the belt flap to a minimum,,,

(more wrap around the pulleys,, etc,,)

20220322_124858

20220322_124858Enter your email address to join: