aggiewoodbutchr

Addicted to ArboristSite

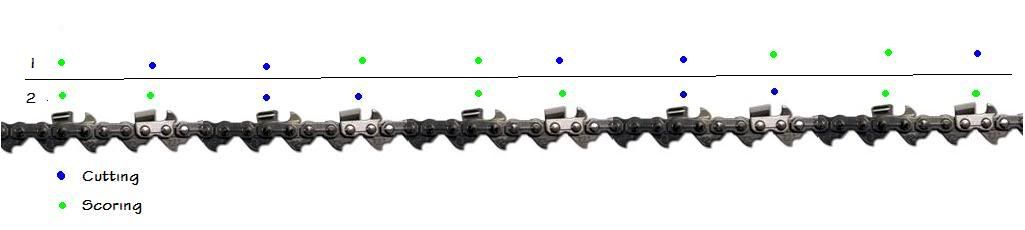

Here's my first go at making a ripping chain similar to what Granberg has pictured on their website. You'll also see the new Maxx chain grinder in action. I looked closely at Stihl and Oregon 511a grinders at local saw shops before I purchased this one. From what I saw, this machine gives you more features, such as automatic clamping and ambidextrous adjustments, than others in it's price range.

I started with WoodsmanPro 33RP 3/8 .063 chain and marked the top plates not to be ground off.

Removed the tops. The diamond wheel paid off here. I tried it on a regular wheel first and it blued the tooth like crazy.

Tops gone.

You can see that I left about 1/32" of the top. If I had ground it off flush the remaining scoring tooth would have been way too thin at the top due to the rounded edge. (Thanks again for the tip, Lakeside)

I started with WoodsmanPro 33RP 3/8 .063 chain and marked the top plates not to be ground off.

Removed the tops. The diamond wheel paid off here. I tried it on a regular wheel first and it blued the tooth like crazy.

Tops gone.

You can see that I left about 1/32" of the top. If I had ground it off flush the remaining scoring tooth would have been way too thin at the top due to the rounded edge. (Thanks again for the tip, Lakeside)

mber of cutters that need to be refiled.

mber of cutters that need to be refiled.