Yokosukadweller

ArboristSite Member

Someone borrowed my impact driver and hasn't returned it, so that was not an option. The rope trick worked out well though.Same here but he’s a newb lol

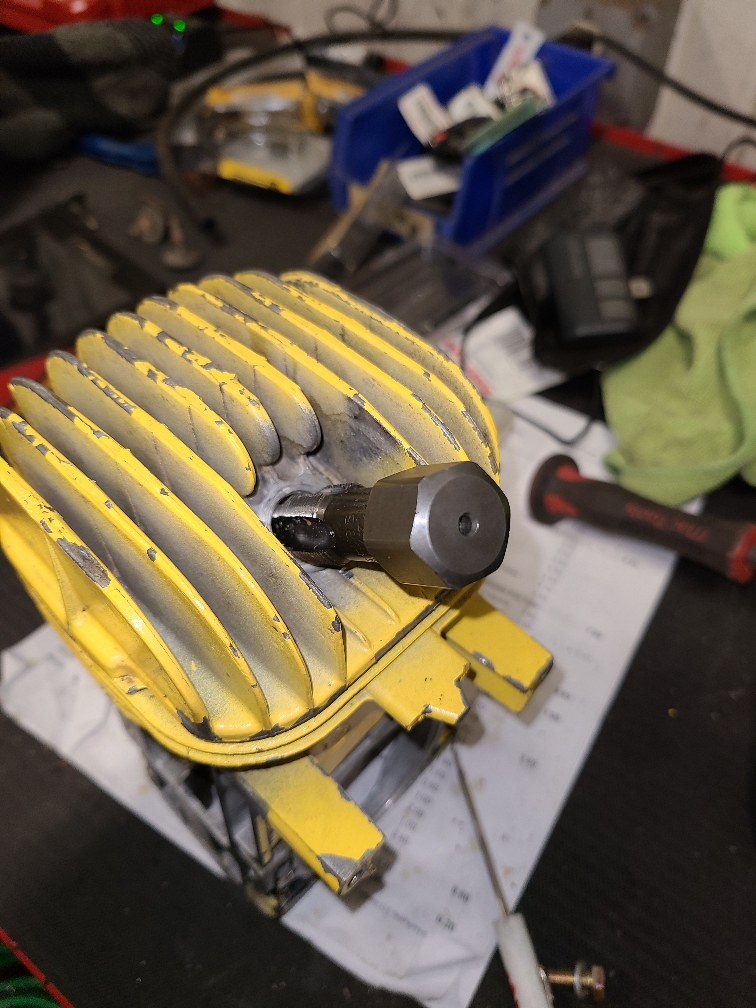

And after abusing the heck out of my daughters old toothbrush, the saw is clean(ish) while waiting for a new flywheel. Hope that'll bring it back to life soon.

Even superchargers

Even superchargers