joeymt33

I bleed YELLOW!

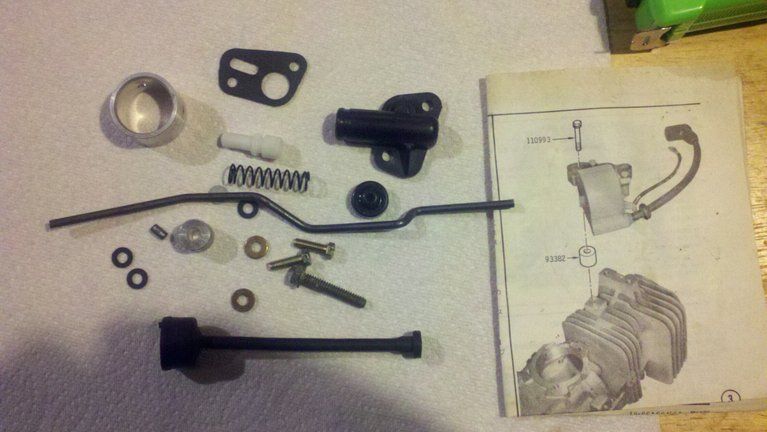

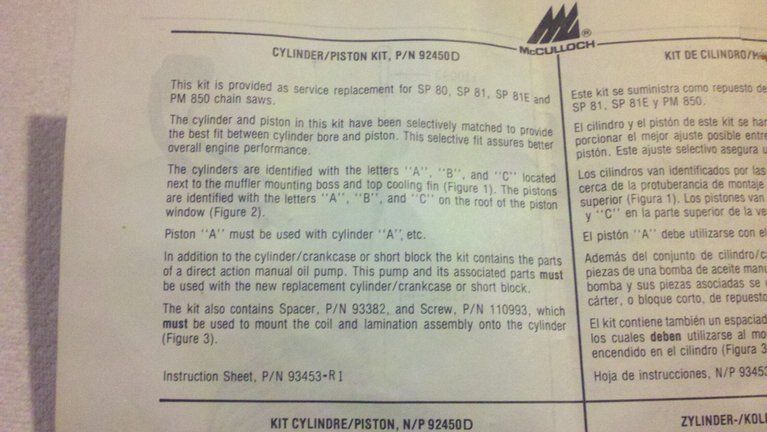

It is sitting in a million pieces on the kids' ping pong table. I started to switch to an electronic coil but the mounts are different. So I may just put it back stock. I still don't have the MAC special screw but I'll find someting else to replace it. Have you noticed the prices SP70s have been bringing on eBay? Might make it hard for me to keep it. Ron

What screw are you looking for?