joeymt33

I bleed YELLOW!

You probably have done most of these but it doesn't hurt to double check

Is the choke lever stripped? Does the choke valve open close?

Can you test compression?

Can you post a pic of the Scoring you noticed?

Have you replaced the spark plug?

Have you verified that the plug gap is .025" exactly? These saws don't like a large plug gap.

Is the muffler or exhaust port plugged?

Check the coil real good. It has insulating washers and in some cases sleeves for the 3 carb mounting screws.

Check under the points cover and make sure it's clean

Check, adjust, clean point gap

Make sure there's not any skint places on the plug wire or ground wire on the coil.

Set the lamination gap around .011"

Check the condenser wire for chafing.

Is the choke lever stripped? Does the choke valve open close?

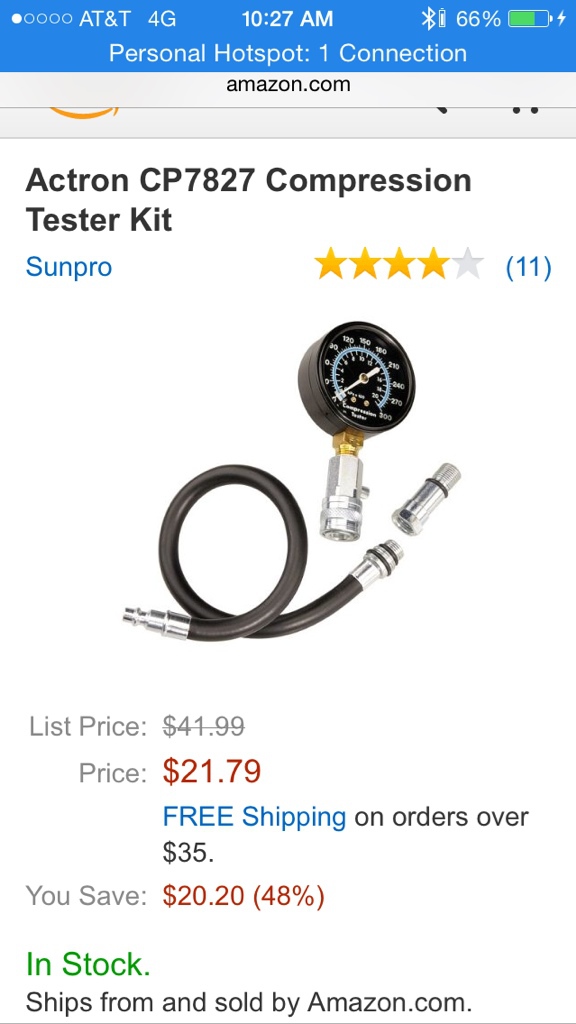

Can you test compression?

Can you post a pic of the Scoring you noticed?

Have you replaced the spark plug?

Have you verified that the plug gap is .025" exactly? These saws don't like a large plug gap.

Is the muffler or exhaust port plugged?

Check the coil real good. It has insulating washers and in some cases sleeves for the 3 carb mounting screws.

Check under the points cover and make sure it's clean

Check, adjust, clean point gap

Make sure there's not any skint places on the plug wire or ground wire on the coil.

Set the lamination gap around .011"

Check the condenser wire for chafing.