jgrady1982

ArboristSite Lurker

Hello,

I picked up this saw about a week ago in non-running condition. Today I started to tear it apart and see why. This is my third Stihl, I also have a MS250, and then a 009L that I bought off of craigslist last year for $50.

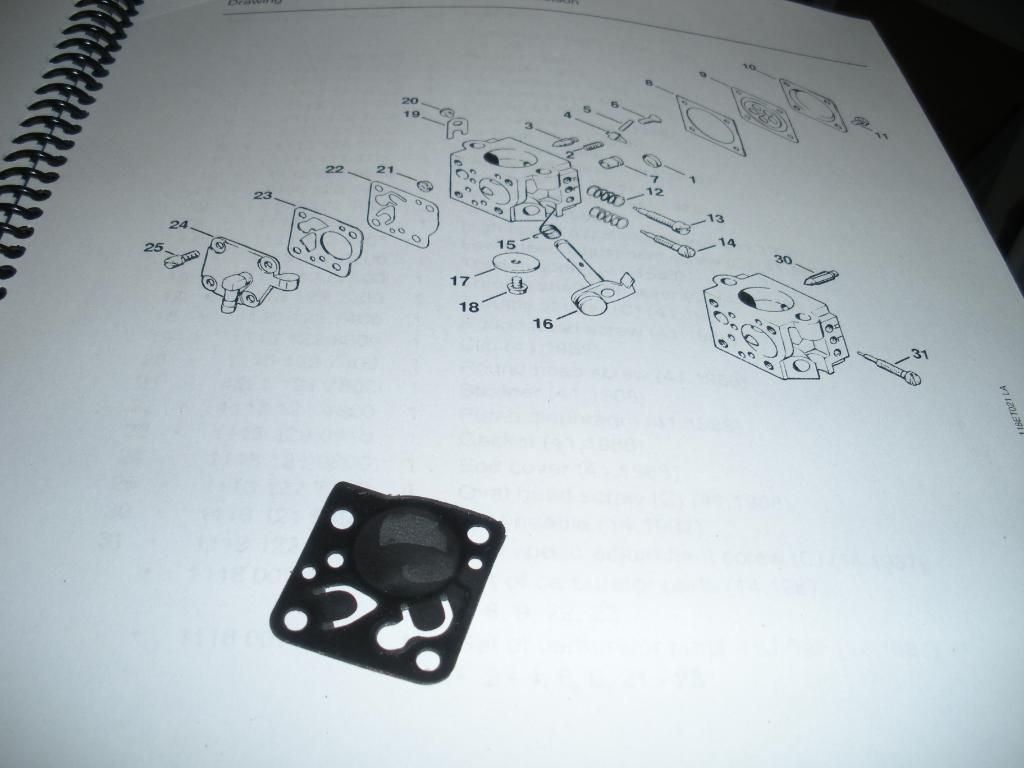

I removed the side bar cover and took off the plastic cover that covers the drive assembly. I was able to remove the drive sprocket and then I stopped when I got to the clutch. I stopped here becuase the crankshaft that it is attached to will moved up and down when I move it with my hand. Is this a broken crankshaft? Or a bad bearing?

I have to try and remove the clutch and then the flywheel later this week. So once I get those guys off it should make the diagnosis much easier. Also, how much of a pain is it to split these cases? I think I saw a thread here of a guy using a modified piece of angle iron to make a case splitter???

Here are the pics: The sharpener stand I made last weekend out of 1/8" steel plate and my Miller Mig 130...set all the way up! There are two bolts with wing nuts that bolt this to my bench, I did not want to sit while I gring my chains, so I made this guy to get them up near my eye level. I used glossy black rust-o-leum paint over a coat of primer. There are 4 triangle braces on the bottom and then one of the backside of the grinder on the top.

I am draining the bar oil into my oil catch pan overnight

Here is my sharpener stand

I picked up this saw about a week ago in non-running condition. Today I started to tear it apart and see why. This is my third Stihl, I also have a MS250, and then a 009L that I bought off of craigslist last year for $50.

I removed the side bar cover and took off the plastic cover that covers the drive assembly. I was able to remove the drive sprocket and then I stopped when I got to the clutch. I stopped here becuase the crankshaft that it is attached to will moved up and down when I move it with my hand. Is this a broken crankshaft? Or a bad bearing?

I have to try and remove the clutch and then the flywheel later this week. So once I get those guys off it should make the diagnosis much easier. Also, how much of a pain is it to split these cases? I think I saw a thread here of a guy using a modified piece of angle iron to make a case splitter???

Here are the pics: The sharpener stand I made last weekend out of 1/8" steel plate and my Miller Mig 130...set all the way up! There are two bolts with wing nuts that bolt this to my bench, I did not want to sit while I gring my chains, so I made this guy to get them up near my eye level. I used glossy black rust-o-leum paint over a coat of primer. There are 4 triangle braces on the bottom and then one of the backside of the grinder on the top.

I am draining the bar oil into my oil catch pan overnight

Here is my sharpener stand