Not that it matters but, when I say stronger I go by feel of saw in cut. Stop watch only backs up what I felt if faster in cut.

You do realize my times show seconds. tenths, hundredths right. There was over a second difference which is 10 tenths to a second and they were further apart then that. :hmm3grin2orange:

I timed at real lumberjack events so I consider myself pretty dang good on stopwatches. Guess what even at the track meets guess what we use stop watches, timing the 40yd dash at football stop watches. The guy that times for me when I'm not timing might be off a tenth or even 2, but I know for fact he isnt off by seconds. :hmm3grin2orange:

I shurg a lot of peoples posted testing methods all the time. They dont take into account, chain, gears, tune, same wood, operators etc etc. :hmm3grin2orange:

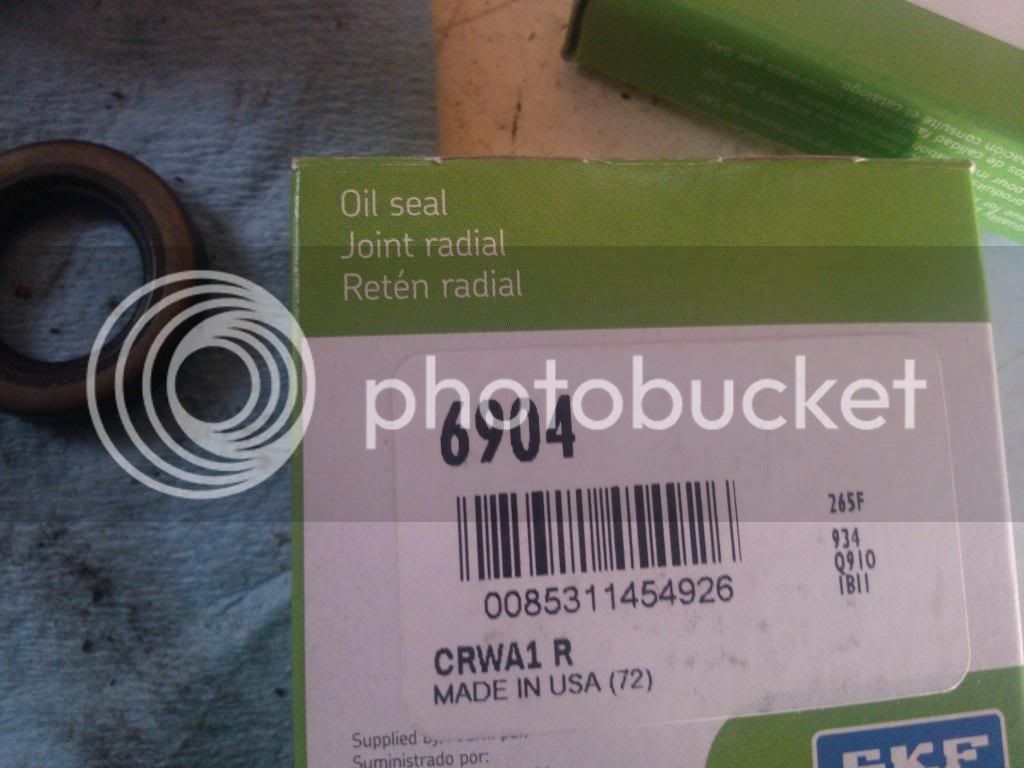

My clutch side checked out good.

My clutch side checked out good.

.

.