chad556

ArboristSite Operative

So my saddle project started out with a NT Vi saddle that i got because it was on clearance. They didnt have mediums so I got the small thinking I could squeeze into it. I could not.

That was ok though because I had just been intrigued by New Tribes Nikosi saddle. Dual floating bridges just makes sense to me and I wanted to try to modify my saddle to have a kind of dual bridge system as well. Also those giant leg pads NT saddles have, aside from looking dumb IMO, are total nutcrackers if you take my meaning:hmm3grin2orange: so I had to do away with those as well.

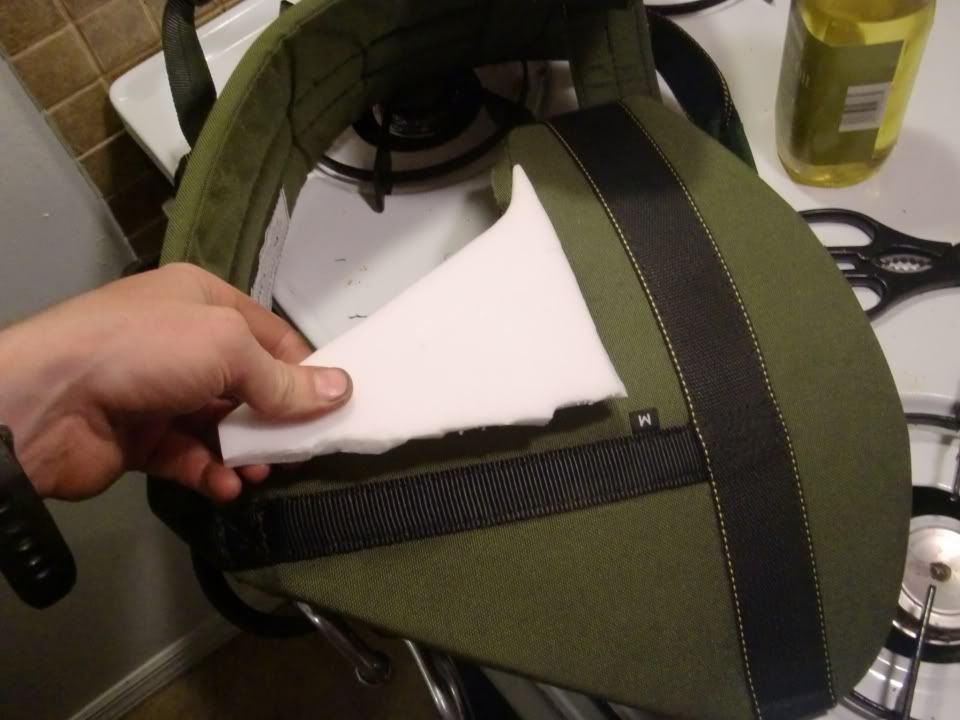

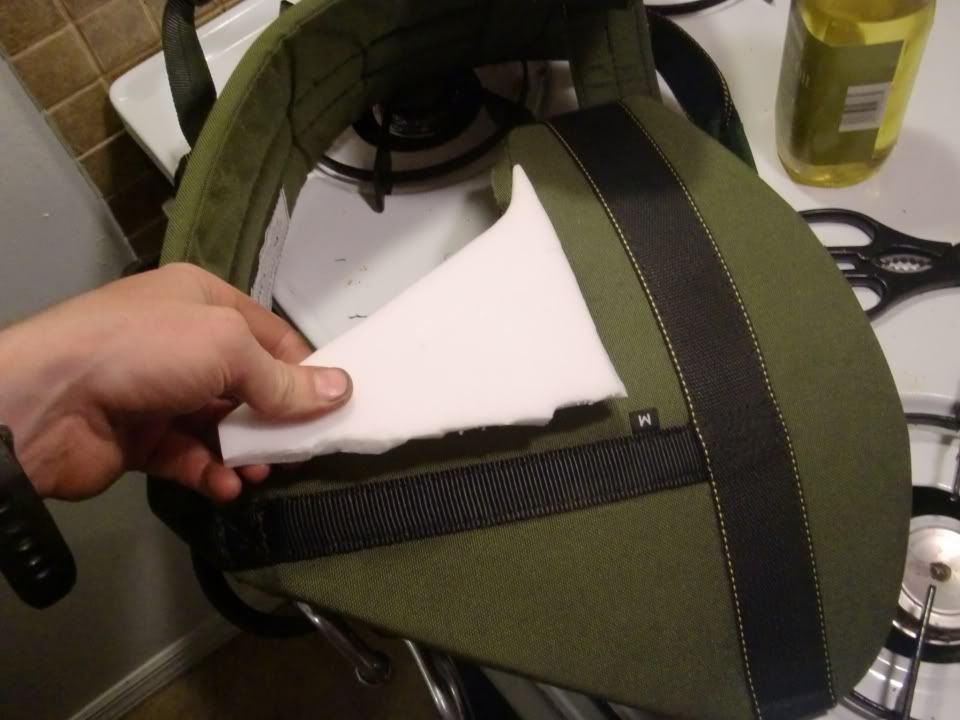

Here is a shot of the bridge I made out of climbspec 1" tubular nylon webbing. Wrapped around twice and then hand sewn with a waxy thread so tough i had a very hard time breaking it with my hands

Here is a shot of my main design consideration, this setup would be super safe because even if the main bridge breaks and fails outright the small webbing link will still hold the delta to you legstraps and vice versa if the webbing link rips apart the main bridge will catch you, giving you(well, me) a sickening scare but still allowing you to reach the ground safely (aka: not in a free fall)

Close up of my stitching work. Its ugly but strong.

And the finished legstraps, note the d-ring belts i sewed on to help keep them from flopping around. They work pretty well but can limit mobility a bit if not adjusted perfectly. (Most importantly no more non-invasive vasectomy action:msp_biggrin

That was ok though because I had just been intrigued by New Tribes Nikosi saddle. Dual floating bridges just makes sense to me and I wanted to try to modify my saddle to have a kind of dual bridge system as well. Also those giant leg pads NT saddles have, aside from looking dumb IMO, are total nutcrackers if you take my meaning:hmm3grin2orange: so I had to do away with those as well.

Here is a shot of the bridge I made out of climbspec 1" tubular nylon webbing. Wrapped around twice and then hand sewn with a waxy thread so tough i had a very hard time breaking it with my hands

Here is a shot of my main design consideration, this setup would be super safe because even if the main bridge breaks and fails outright the small webbing link will still hold the delta to you legstraps and vice versa if the webbing link rips apart the main bridge will catch you, giving you(well, me) a sickening scare but still allowing you to reach the ground safely (aka: not in a free fall)

Close up of my stitching work. Its ugly but strong.

And the finished legstraps, note the d-ring belts i sewed on to help keep them from flopping around. They work pretty well but can limit mobility a bit if not adjusted perfectly. (Most importantly no more non-invasive vasectomy action:msp_biggrin

.

.