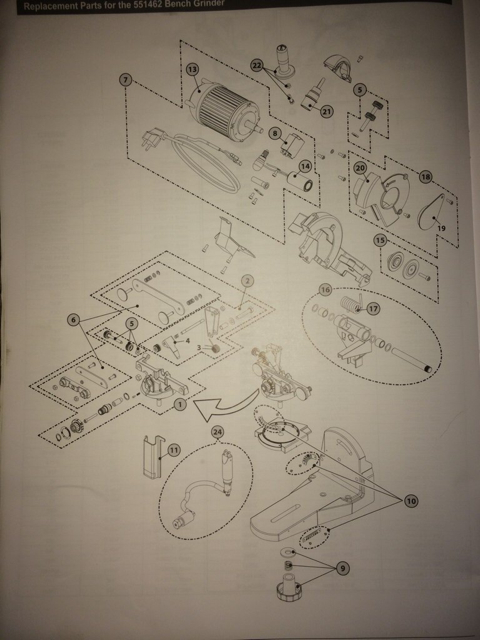

For example.... MY grinder set forward 15 degrees:

Now MY grinder set back 15 degrees:

You can see that adjustment only moves the vice closer and farther away from the back of the grinder regardless of vice angle, NOT push the top plate farther into or away from the side of the wheel.

Sent from my iPhone using Tapatalk

drd-

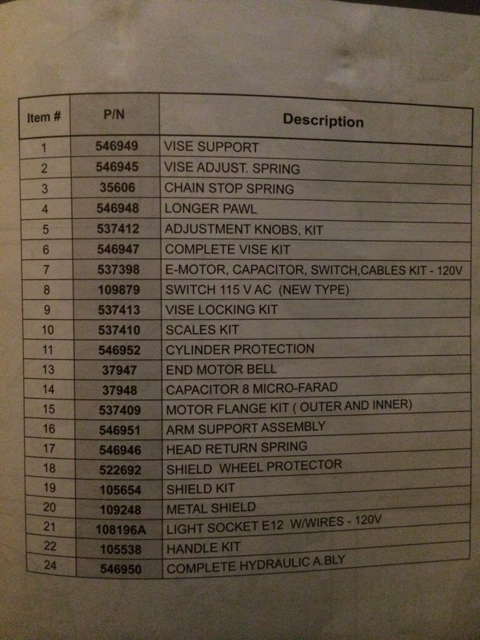

thanks for the pictures. i can see your problem now. maybe "self-centering" really means "ain't-centering." if you decide to keep the grinder you can use a trick that i use for evening top plates. figure out the thread pitch of the machine screw that positions the chain stop. it could be that the pitch is 1.5mm which would mean one 360 degree turn would put your cutter exactly where you want it. if it is something other than 1.5mm a little work with a calculator will give you the number of degrees you need to turn it. translate that into hours on a clock face. after a few chains it will become "automatic." i use that technique to advance my chain stop by .1mm's. by the way, the reason the side scale is marked in degrees is because it is intended to let you "twist" the cutter face, the same as tilting the file vertically. most chisel chains call for that additional angle but many operators ignore it.