Hi all,

i hope that the overheating has been remedied, and i thought that I'd update the details of my motorized draft door, and the water-jacketing of my furnace door. Unfortunately I don't have better pictures, as I finished this right as I needed to put it into service again, and now I'm not home during daylight too often.

The following modifications were done to a Ridgewood stove that can ben seen here:

http://ridgewoodstove.net/

I don't have pictures of the process, as I didn't want to pontificate on the virtues of my modifications without knowing that they would even work.

These stoves are a budget deal, and that's what they are targeting. They serve that purpose well. Nothing on this stove is cutting edge, but they

are serving a market that suits them. I used this unit, new but second-hand as delivered for the first year without too many issues. The draft solenoid died

once leaving us without controlled burn, however opening the draft door a very small amount took care of that until received another solenoid.

Having a pretty good knowledge of how these things work, and being a bit of a hack with a welder allowed me to make a decision to make a few modifications.

Unfortunately, my timing, the end of summer, the coming birth of my son, and my general lack of documentation skills left me with no pictures of the process

and very few quality pics of the "finished" product. I make fun of that, as "finished" is relative. If this were for showing, or sale, etc. I would have

made the finishing much more aesthetically pleasing.

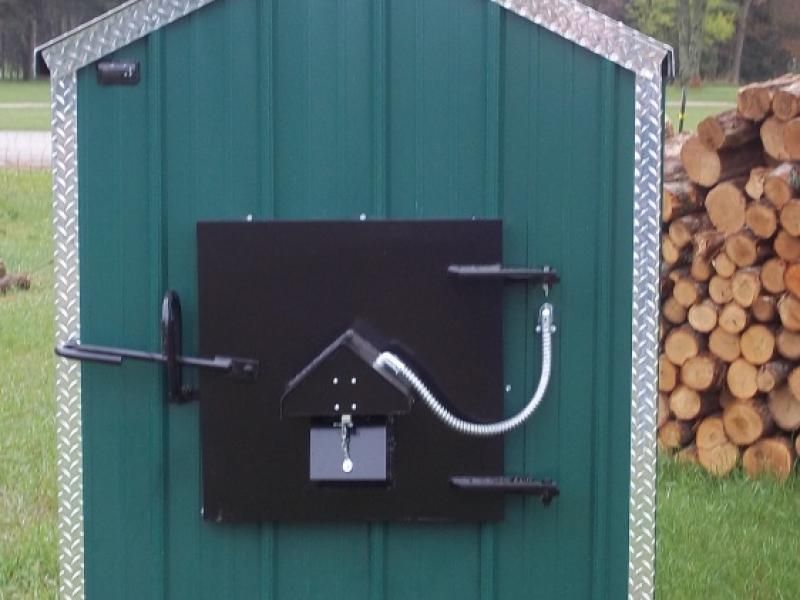

Here is a shot of the finished product:

The first thing that I did was to remove the loading door and haul it up to the garage in my tractor. It's a bit heavy, and wasn't my favorite thing to lift.

(I've lifted plenty in my short 30 years, and having a desk job now makes me realize that lighter is better)

My model had solid welded 1.5" cavity that held fiberglass insulation. I removed this with my trusty torch and did a bit of grinder cleanup on the cuts

and removed the fiberglass. I cut 2 holes on the front of the door and welded half of a 1/2" pipe coupler to the front of the door

making sure that the upper outlet was the absolute highest point on the water jacket. The other half was welded to the bottom

of the front of the door as an inlet.

The cavity went back on, and was completely welded all around water tight. I made sure that the small space under the draft port

had room for water to travel, as hot spots are bad news.

You'll see in the picture above that there are what apprear to be 3 hoses coming from the door. The top one is the upper door water

outlet. This MUST be kept sloping upward along its full length, as any humps will allow trapped air to accumulate.

The second 'hose' is the corrugated steel electrical conduit for the draft motor.

The bottom hose is the lower door water inlet. This connects to the water jacket of the boiler and allows "cold" water to be drawn into the door

by thermosiphon, (the same effect of a side-arm heater on a hot water tank).

After welding the water jacket back to the door I needed to make some other improvements, and that was to limit the travel of the latch handle.

That was perhaps the easiest part. I marked the limits that it needed to travel to function, and then welded 2 small pieces of steel to the door

which prevent the handle from dropping or rising too far.

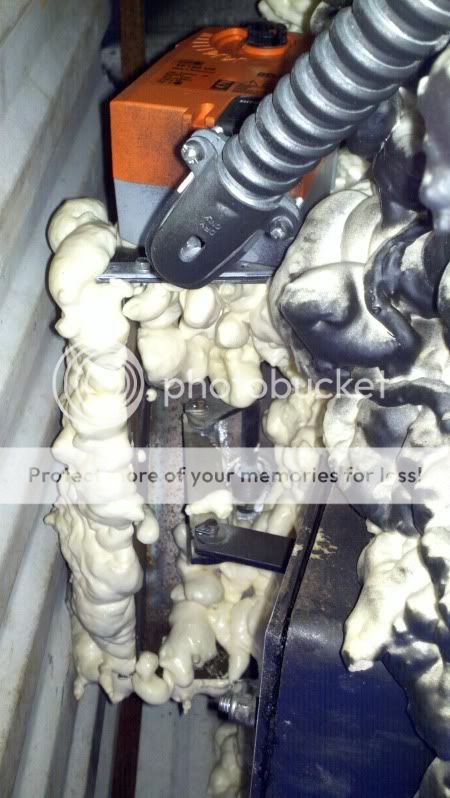

See below:

I know it's tough to see around all the foam insulation.

With the handle taken care of, I moved to the draft door.

This was formerly handled by a simple 120v solenoid that would slam the door open when the contoller supplied the current. It would then slam shut

when current was cut off. Unfortunatly, I don't believe that they are rated for a job that's as hot as this one, and they didn't seem to like being on

for extended time either.

Again, I don't have very good pics, and I don't have all day to draw pictures, but I hope you can get the idea from the pics that are here.

What you see in the pic. above is the draft door, a small lever arm welded to the door, a link bar, a small lever arm wleded to a 3/8 rod.

This 3/8 rod passes through the "roof" on the door as seen below:

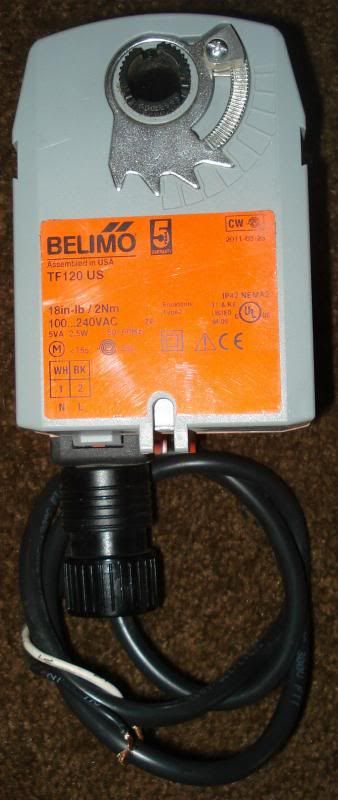

With the rod passing through the "roof" it then passes into the draft motor which is a TF 120 from Belimo, which seems to be all over ebay.

You definitely want a "spring return" unit that's designed to run on the output from the temperature controller, which in this cas is 120v ac nominal.

Below are a few pictures that I was able to take with my phone when I loaded it the other night.

Here is the finished deal again.

Keep in mind that the draft door and spray foam will not work without water-jacketing the door. Without

water inside the door, the steel temperatures can get up to 1000°F on occasion.

It's a gamble how hot a draft motor will operate.

The insulation that I used is simple "Great Stuff" that's all over the home improvement stores. It seems to work well enough, but I'm

sure that simple fiberglass batting would work too. I selected it knowing that it would stay put after sptraying, and it allowed me to keep the bottom of the

trimming open for draft air to enter.

The other thing to note is that the front plate of the furnace is not water jacked on this model. I added another plate of steel to the inside of my firebox

and allowed water to fill that cavity as well. What i did there was to cut 4" x 1" windows in 8-10 places on the very front of the circular portion of the

firebox, and then spaces steet 1.5" away from the front wall and welded solid. You may be able to see where I extended the firebot into the chamber below.

The addition of the water jacketing has increased heat transfer area by a significant amount while also keeping more of the heat out of the atmosphere.

I'm pretty happy with the install so-far.

I see to have cut down on wood usage, and I'm not worried about the solenoid dying. (I kept it for backup)

The only issue that I've had so far happened when I filled the stove very full with wood and there was raging fire immediately agains the door.

This caused the water inside the door to boil as it could not circulate our of the door quickly enough. I have ideas about how to fix that that involve

larger hoses, partial porced circulation, and other things, but for the mean-time, I just don't pile all the wood right by the door and I have not heard

the door water boiling any since.

Thanks for reading, and feel free to ask about details. Again, sorry for the lack of in-process pictures, or even better finished pics.

I hope you get the idea.

Also,

This is not me saying that this is what you should do, as it almost certainly violates warranty, etc. I'm ok with that as it was a second hand deal for me.

Take care,

Phill