Chris-PA

Where the Wild Things Are

I thought I'd start a thread for tools and techniques for porting saws when you don't want to pony up for a Foredom grinder and right angle hand pieces and the like.

My first advice for cheap porting is to port cheap saws - don't risk something expensive.

Second, recognize that there are some operations/modifications that you won't be able to do properly, so you might have to compromise and work around that - but this does not mean you can't make a very good running saw.

Third, but most important, is that knowledge doesn't cost money. Just because you have not spent big bucks on tools doesn't mean you can't fully understand what you are doing, and in fact that is what allows one to get good gains without spending a bunch. There is a lot that can be learned by reading threads here.

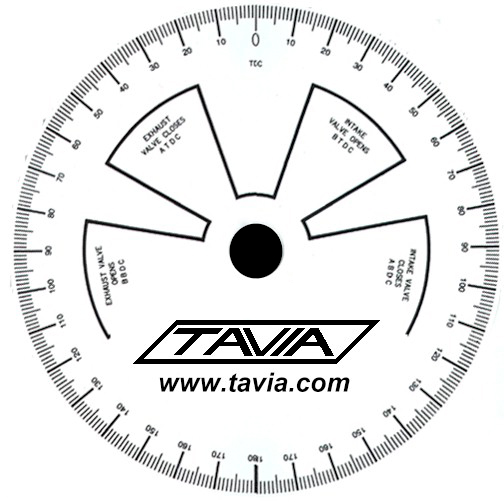

With that in mind, there are some things you will need to be able to do, especially including measuring port timing. You can do this by means of careful linear measurements, knowing the stroke, piston height, squish clearance and rod length, and then doing some careful drawing and a little trigonometry. However, this is really too much of a PITA to be worth it, and has accuracy issues, so you'll need a degree wheel. You can make one out of a CD and a printed label. I cheated here and turned a mounting bushing at work on the old lathe, but there are other ways, such as an only drill chuck.

Regardless of how you do it, you need the angle numbers to do an effective job.

Next, you will need something to grind on ports. I use a cheap Dremel clone from HF and a variety of tips, but mostly a 1/8" carbide cutter from the hardware store. However, I have a secret weapon - my $10 HF Rotary Tool. This thing is a real POS - it has no front shaft bearing and is basically a toy motor with a small chuck stuck on the shaft. However, it is quite small and comes with some diamond grit tools. It's no right angle hand piece, but it does help get into smaller places and helps with port edges. I've actually ported several engines using only this tool, and I can't believe it still works.

While you're at HT you might want to pick up some measuring tools, like these, although a little better caliper would be good:

The inside spring caliper is good for measuring port widths.

I'll try to add more info later and I hope others will add tools, tips and techniques for economical porting.

My first advice for cheap porting is to port cheap saws - don't risk something expensive.

Second, recognize that there are some operations/modifications that you won't be able to do properly, so you might have to compromise and work around that - but this does not mean you can't make a very good running saw.

Third, but most important, is that knowledge doesn't cost money. Just because you have not spent big bucks on tools doesn't mean you can't fully understand what you are doing, and in fact that is what allows one to get good gains without spending a bunch. There is a lot that can be learned by reading threads here.

With that in mind, there are some things you will need to be able to do, especially including measuring port timing. You can do this by means of careful linear measurements, knowing the stroke, piston height, squish clearance and rod length, and then doing some careful drawing and a little trigonometry. However, this is really too much of a PITA to be worth it, and has accuracy issues, so you'll need a degree wheel. You can make one out of a CD and a printed label. I cheated here and turned a mounting bushing at work on the old lathe, but there are other ways, such as an only drill chuck.

Regardless of how you do it, you need the angle numbers to do an effective job.

Next, you will need something to grind on ports. I use a cheap Dremel clone from HF and a variety of tips, but mostly a 1/8" carbide cutter from the hardware store. However, I have a secret weapon - my $10 HF Rotary Tool. This thing is a real POS - it has no front shaft bearing and is basically a toy motor with a small chuck stuck on the shaft. However, it is quite small and comes with some diamond grit tools. It's no right angle hand piece, but it does help get into smaller places and helps with port edges. I've actually ported several engines using only this tool, and I can't believe it still works.

While you're at HT you might want to pick up some measuring tools, like these, although a little better caliper would be good:

The inside spring caliper is good for measuring port widths.

I'll try to add more info later and I hope others will add tools, tips and techniques for economical porting.