z50guru

errr..

So anyone that owns one of these saws knows the air filters are nearly impossible to get hold of anymore.

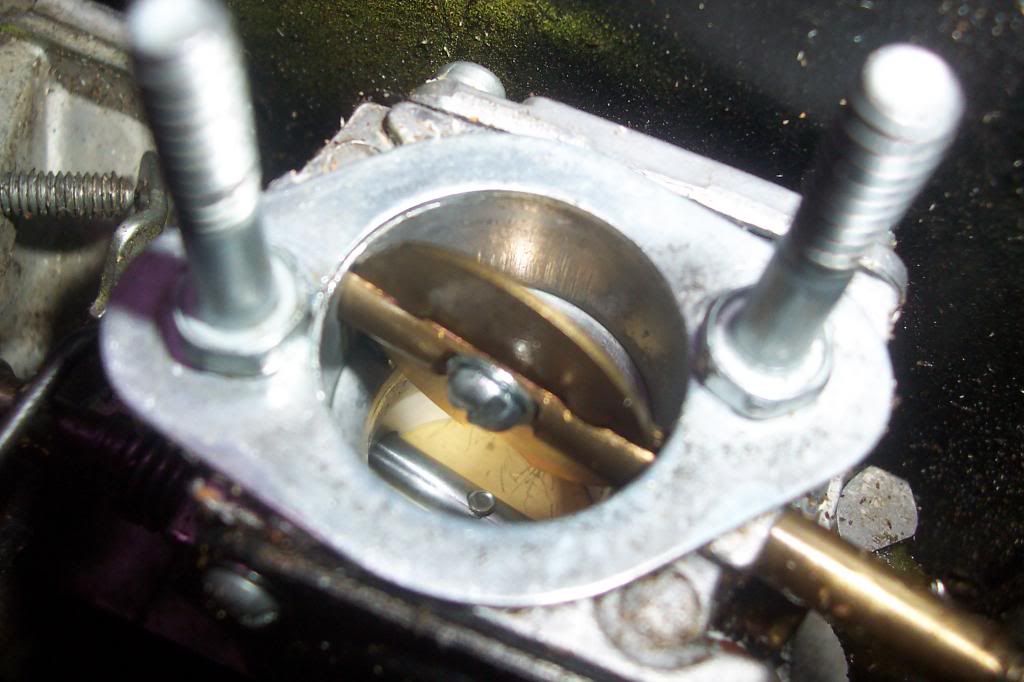

I recently got this 5200 with the flocking having been ingested over time.

I tried sandwiching some foam between the two halves of the cage, but found this method too restrictive. So i took a spin over to a surplus fabric outlet and came home with this "Interface". This material is non restrictive and similar to material used for vacuum bags.

With the above items, its possible to make a really nice clean fix. I simply sprayed the cage assy with adhesive and applied to the interface. I used a hobby knife to then remove the extra material and used my fingers to apply pressure between the plastic ribbing forming the interface to the screen as well.

I used a Q tip and some rubber cement just around the edges of the filter. Just a bit extra to prevent the material from lifting.

Im pleased with the results and really looking forward to finally putting this old hammer to some wood.

I recently got this 5200 with the flocking having been ingested over time.

I tried sandwiching some foam between the two halves of the cage, but found this method too restrictive. So i took a spin over to a surplus fabric outlet and came home with this "Interface". This material is non restrictive and similar to material used for vacuum bags.

With the above items, its possible to make a really nice clean fix. I simply sprayed the cage assy with adhesive and applied to the interface. I used a hobby knife to then remove the extra material and used my fingers to apply pressure between the plastic ribbing forming the interface to the screen as well.

I used a Q tip and some rubber cement just around the edges of the filter. Just a bit extra to prevent the material from lifting.

Im pleased with the results and really looking forward to finally putting this old hammer to some wood.