You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rakers

- Thread starter wavefreak

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

mtngun

Addicted to ArboristSite

There are several store-bought gages for filing rakers.

I'm currently using the Filemate gauge. It works well when it is new, but over time my file has cut into it so that the gage is no longer accurate. The gage metal does not seem to be hard enough, to my way of thinking.

http://www.baileysonline.com/itemdetail.asp?item=15225&catID=9954

I bought a Carlton File-O-Plate gauge. Supposedly it is a better design, that compensates for tooth wear. But, you need a different File-O-Plate for each type of chain you use. And personally, each time I use it, I have to look up the instructions on the internet. It's not very intuitive to use, so I usually reach for the Filemate, instead.

http://www.baileysonline.com/itemdetail.asp?item=65986&catID=9952

There are other brands out there, those are just two that I have experience with.

Sometimes, instead of using a gage, I simply give each raker 2 strokes. In theory, this is not a repeatable method, and may result in uneven rakers. However, it is quick, easy, and you can get away with it once in a while.

In all cases, a fresh, name brand file makes the job easier. The hard chain dulls files rather quickly, so be prepared to replace the file from time to time.

I'm currently using the Filemate gauge. It works well when it is new, but over time my file has cut into it so that the gage is no longer accurate. The gage metal does not seem to be hard enough, to my way of thinking.

http://www.baileysonline.com/itemdetail.asp?item=15225&catID=9954

I bought a Carlton File-O-Plate gauge. Supposedly it is a better design, that compensates for tooth wear. But, you need a different File-O-Plate for each type of chain you use. And personally, each time I use it, I have to look up the instructions on the internet. It's not very intuitive to use, so I usually reach for the Filemate, instead.

http://www.baileysonline.com/itemdetail.asp?item=65986&catID=9952

There are other brands out there, those are just two that I have experience with.

Sometimes, instead of using a gage, I simply give each raker 2 strokes. In theory, this is not a repeatable method, and may result in uneven rakers. However, it is quick, easy, and you can get away with it once in a while.

In all cases, a fresh, name brand file makes the job easier. The hard chain dulls files rather quickly, so be prepared to replace the file from time to time.

KodiakKen

ArboristSite Operative

just a thought

before you lay your depth gauge tool on the chain. lay a piece of the thinnest tape you can find across it..save the tool with a few seconds of effort

before you lay your depth gauge tool on the chain. lay a piece of the thinnest tape you can find across it..save the tool with a few seconds of effort

Constant raker depths or heights work ok for a while but as the chain wears the cutter gullet becomes wider making the cutting angle gets shallower so the cutter loses efficiency and starts to make increasingly more powder than chips. As a chain becomes less effective, users start to sharpen them more often but they then cut even less effectively so they sharpen them more and eventually throw the chain away well before the end of it's real lifetime. What is needed is not a constant depth but a constant cutting angle so as the cutter wears the raker height has to be dropped much more than 0.025" to continue to make chips.

As Mtngn says, Fileoplates gauges do this automatically but I use digital vernier calipers as does AggieWoodButcher. I also vary the angle depending on what I'm cutting although I generally stay @ 6º. While this sounds completely anal, but I do not bother setting them to within 0.001" as log as they are within 0.005" that's close enough for me.Here's a link shoing how I do mine.

here are some of my litany of posts about this matter

http://www.arboristsite.com/showpost.php?p=1188688&postcount=20

And Here

http://www.arboristsite.com/showpost.php?p=1358118&postcount=2

And Here

http://www.arboristsite.com/showpost.php?p=1447904&postcount=6

And here

http://www.arboristsite.com/showpost.php?p=1534631&postcount=8

And Here

http://www.arboristsite.com/showpost.php?p=1517183&postcount=7

As Mtngn says, Fileoplates gauges do this automatically but I use digital vernier calipers as does AggieWoodButcher. I also vary the angle depending on what I'm cutting although I generally stay @ 6º. While this sounds completely anal, but I do not bother setting them to within 0.001" as log as they are within 0.005" that's close enough for me.Here's a link shoing how I do mine.

here are some of my litany of posts about this matter

http://www.arboristsite.com/showpost.php?p=1188688&postcount=20

And Here

http://www.arboristsite.com/showpost.php?p=1358118&postcount=2

And Here

http://www.arboristsite.com/showpost.php?p=1447904&postcount=6

And here

http://www.arboristsite.com/showpost.php?p=1534631&postcount=8

And Here

http://www.arboristsite.com/showpost.php?p=1517183&postcount=7

Last edited:

mtngun

Addicted to ArboristSite

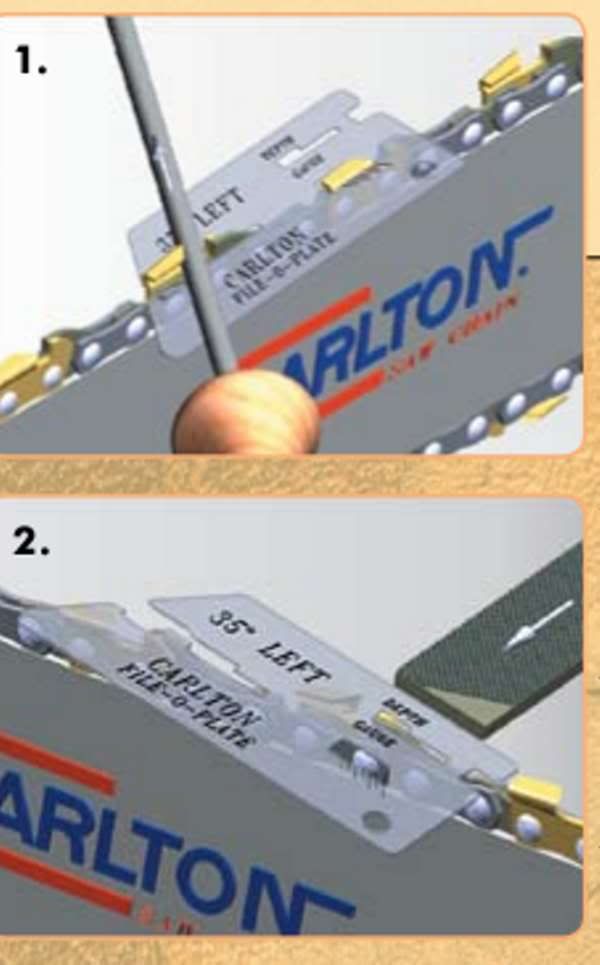

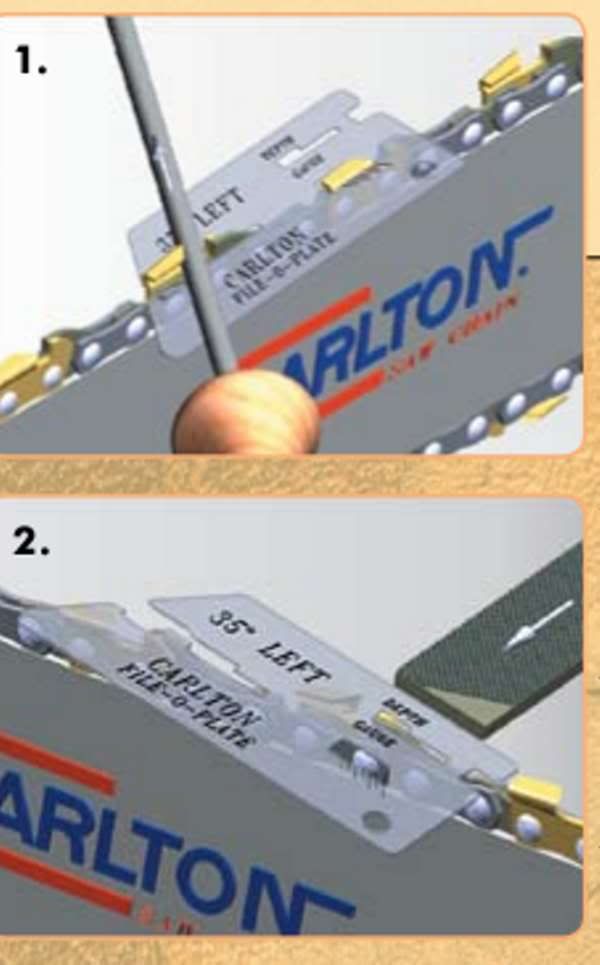

While there are no instructions provided with the File-O-Plate, I found this illustration on the Carlton website. It's as clear as mud.

Despite the befuddled instructions, I settled upon a consistent way to use the FOP, and applied it to a couple of milling chains. It was quick and easy to use -- once I had the system figured out.

The FOP set the rakers more aggressively than a standard raker gauge.

I haven't had a chance to mill with the FOP'd chains yet. More pics and feedback after some field work.

BobL's method of using a digital caliper doesn't sound too bad, either.

Despite the befuddled instructions, I settled upon a consistent way to use the FOP, and applied it to a couple of milling chains. It was quick and easy to use -- once I had the system figured out.

The FOP set the rakers more aggressively than a standard raker gauge.

I haven't had a chance to mill with the FOP'd chains yet. More pics and feedback after some field work.

BobL's method of using a digital caliper doesn't sound too bad, either.

From the CS that various people bring to me to take a look at, rakers are one of the poorest maintained components of a CS and that's because few people understand that raker depths and raker profile contribute significantly to the cutting action

Here are a few raker profiles - the orange line is shown offset for clarity - it should really be starting on the LHS like the others

As well as not increasing the raker depth with increasing gullet size, even if the back edge is rounded over, conventional raker gauges leave the top of the raker too flat (orange line). The more the raker is filed the flatter it gets so its ability to penetrate the wood decreases leading to to reduced cutting speed.

Filoplates (and grinders) place bit of angle on the raker profile (green) line, they are useful for getting the raker down to the correct depth, which is better than conventional gauges, but the rakers still need a touch up to smooth the edges.

More aggressive cutting actions can be obtain by making the raker increasingly pointy starting with the black then red then blue all the way thru to the brown line. In Aussie hardwood I run on the blue line. These profiles can only really be done by hand or using a grinder and then a touch up with a hand file

Here are a few raker profiles - the orange line is shown offset for clarity - it should really be starting on the LHS like the others

As well as not increasing the raker depth with increasing gullet size, even if the back edge is rounded over, conventional raker gauges leave the top of the raker too flat (orange line). The more the raker is filed the flatter it gets so its ability to penetrate the wood decreases leading to to reduced cutting speed.

Filoplates (and grinders) place bit of angle on the raker profile (green) line, they are useful for getting the raker down to the correct depth, which is better than conventional gauges, but the rakers still need a touch up to smooth the edges.

More aggressive cutting actions can be obtain by making the raker increasingly pointy starting with the black then red then blue all the way thru to the brown line. In Aussie hardwood I run on the blue line. These profiles can only really be done by hand or using a grinder and then a touch up with a hand file

billstuewe

ArboristSite Operative

I have been using the Pferd filing system since 2001 and in about 2005 also got a Speed Sharp grinder. I have had what I thought was success using the grinder to lower the rakers. It came with a right angle (flat edge) wheel which I used the first time but have since just used the regular grinding wheel. I raise the angle of the grinder from 60º to 90º and set the stop so that I take the required amount off as I slide the raker under the spinning wheel held down against the grinder stop (the chain clamp is set so that the chain will just barely slide through--minimum slop) I have been measuring the distance by laying a flat edge on top of the teeth and using a feeler gauge of .025 or .030. I have learned today that I need to set it at 10% of the gullet distance (thank you BobL for that wisdom) I have noticed my chains cut slower as the tooth is filed way back--now I know why and how to correct! I also adjust the clamping base for the chain forward or backward so that the chain is centered on the grinding wheel. So far I do not feel that I have messed up any chains.

There was some discussion about clamping and filing on the saw without sitting on it--Here is what I use:

I made it out of red oak with ample room for the bottom teeth to pass and 1/2" all-thread with nuts/washers welded appropriatly to make the clamp work. The front half is fastened to the 3/4" plywood and the back half is free to slide in and out. 10º marks on on top for angle gauges. It is sized for my saw mounted to the Logosol sled carrage--works great.

A nut is welded to each side of a washer, the washer is screwed to the back and the all-thread can turn inside it. Not shown is another nut and washer welded together and screwed to the front. I put a piece of plastic hose on the all-thread inside the clamp so if my teeth hit it they would not contact the metal. A red marker is ready to mark the start tooth.

There was some discussion about clamping and filing on the saw without sitting on it--Here is what I use:

I made it out of red oak with ample room for the bottom teeth to pass and 1/2" all-thread with nuts/washers welded appropriatly to make the clamp work. The front half is fastened to the 3/4" plywood and the back half is free to slide in and out. 10º marks on on top for angle gauges. It is sized for my saw mounted to the Logosol sled carrage--works great.

A nut is welded to each side of a washer, the washer is screwed to the back and the all-thread can turn inside it. Not shown is another nut and washer welded together and screwed to the front. I put a piece of plastic hose on the all-thread inside the clamp so if my teeth hit it they would not contact the metal. A red marker is ready to mark the start tooth.

Nice setup Bill!

That 10% of gullet distance value gives a 6º cutter angle like this.

To maximize cutting speeds, different cutter angles should be used for different type of woods. For softer woods higher angles can be used, so 11% or 12% of gullet width will give even higher cutting speeds. For really hard wood something like 8% and a reduced cutter hook will give reasonable cutting speed and not blunt the cutter too quickly.

I have been measuring the distance by laying a flat edge on top of the teeth and using a feeler gauge of .025 or .030. I have learned today that I need to set it at 10% of the gullet distance (thank you BobL for that wisdom) I have noticed my chains cut slower as the tooth is filed way back--now I know why and how to correct!]

That 10% of gullet distance value gives a 6º cutter angle like this.

To maximize cutting speeds, different cutter angles should be used for different type of woods. For softer woods higher angles can be used, so 11% or 12% of gullet width will give even higher cutting speeds. For really hard wood something like 8% and a reduced cutter hook will give reasonable cutting speed and not blunt the cutter too quickly.

wavefreak

Addicted to ArboristSite

I give up.

I'm just going to but a CNC machine. That should get it right. Either that or a 10 gigawatt laser on the Alaskan instead of a Stihl.

BobL - I want to thank you for sharing your knowledge. I had no idea how nuanced sharpening a chain really is.

I'm just going to but a CNC machine. That should get it right. Either that or a 10 gigawatt laser on the Alaskan instead of a Stihl.

BobL - I want to thank you for sharing your knowledge. I had no idea how nuanced sharpening a chain really is.

BobL - I want to thank you for sharing your knowledge. I had no idea how nuanced sharpening a chain really is.

No worries, but it's not anywhere near as nuanced as perhaps as what I write. I'm known for over analysing stuff, but that's just my investigative training showing thru.

I also know guys that sort of wave a few files and gauges in the general direction their chain and don't worry about any of the fine detail crap and just cut, well sort of cut. Either they're lucky/natural or they don't care, but they end up making sawdust and they get their stuff milled and they're happy enough and good on them! But yes CS chain is a very wierd beast.

Although I learn things for myself by experimenting - I'm really riding on the shoulders of giants. I learned quite a bit of stuff from my dad who in the 1950s had 350 cc (8 HP) two man two stroke with an 8 ft bar and used it to cut down 8 ft diameter 250+ ft tall karri hardwoods. He used to spend up to 4 hours of an 8 hour day tinkering with that thing and sharpening his chains. He never analysed things like I do and just did it by mainly by trial and error.. There are some things he didn't know. For example, he always used a constant raker height. I discovered increasing raker heights only two years ago reading a Carlton Chain manual. Using that I can now get the same cutting performance when the cutters on a chain are so short the chain is just about ready to be thrown away as I do when the chain is brand new. I still learned a lot from my dad - I wish he were alive today - I never really did pick his brains before he passed away.

The other guy I'm learning heaps from is Jeff - owner of the tree loping yard. He can just listen to a saw and tell me how to tweak this and that to improve cutting.

But best of all has been the good folks on this site - the collective contribution is awesome - we all play our part.

mtngun

Addicted to ArboristSite

CSM'ers are highly motivated to sharpen their chains well. Milling has motivated me to learn more about chains and saws and trees and lumber and forestry and logging........

Back in the days when I just cutting firewood, I was perfectly content running a disposable Poulan and using whatever chain was on sale and sharpening with whatever file I had laying around. I didn't know or care about the different tree species because they all burned and kept me warm.

That's why this thread is on the milling forum, not the chainsaw forum or the sharpening forum.

Back in the days when I just cutting firewood, I was perfectly content running a disposable Poulan and using whatever chain was on sale and sharpening with whatever file I had laying around. I didn't know or care about the different tree species because they all burned and kept me warm.

That's why this thread is on the milling forum, not the chainsaw forum or the sharpening forum.

CSM'ers are highly motivated to sharpen their chains well. Milling has motivated me to learn more about chains and saws and trees and lumber and forestry and logging........

Back in the days when I just cutting firewood, I was perfectly content running a disposable Poulan and using whatever chain was on sale and sharpening with whatever file I had laying around. I didn't know or care about the different tree species because they all burned and kept me warm.

That's why this thread is on the milling forum, not the chainsaw forum or the sharpening forum.

Yep - I Agree.

The first thing I milled (about 3 years ago) was a pine branch about 10" in diameter. The saw was a 35+ year old Mac 10-10 (great little saw) with a 16" bar. The chain was old and sort of sharp but it didn't really matter. About a year later I'm using an 076 with a 30" redgum and the a year after that up 48" lemon scented gum. These graduated experiences help me hone my sharpening skills. If I had started with the big lemon scented gum this stuff is so hard and my chain sharpening skills were limited I would have cut a couple of slabs and then given it away. That's why I advise Aussie CS millers to start milling something small eg 20 " and practice their cutting and sharpening techniques to suit what they are cutting before the try big stuff.

Similar threads

- Replies

- 4

- Views

- 472