Opihi59

ArboristSite Operative

I lent my saw to a shady contractor friend reluctantly. When I got it back, the bar and chain were charred, oil was empty, and it looks like there is something wrong with the chain sprocket but I am not sure. There is a collar around the sprocket that is now floating. It can shift from the left to the right along the length of the sprocket and I am not sure whether it was orginally secured against the clutch assembly to the left side or against the saw body to the right. Can anyone help with either words and/or a picture? If it cannot operate this way I will make him pay for the fix. If it is broken, does anyone have an available spare to sell?

Larry

Sigh. The leading cause of chainsaw demise, worldwide. Lending treasured saw to someone who is totally unencumbered with knowledge or experience in operating them. If you're lucky, it wasn't straight-gassed.

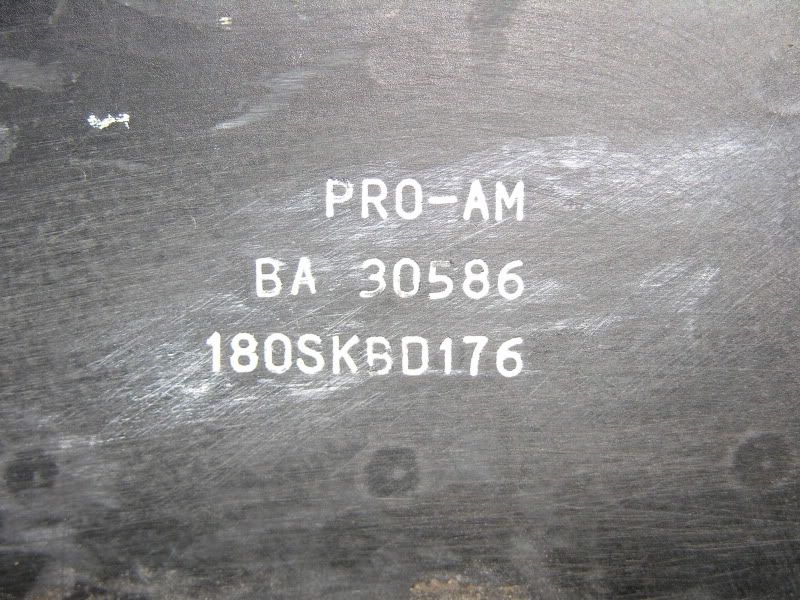

In regards to the bar, this particular bar is a D176 mount, which is not the mount this saw was designed to utilize. The problem is that you can't find the original bar any longer. One of these holes I drilled, and pretty sure it would be the ROUND one. When I cut oblong holes, I gotta drill 2 then connect with a round file and dress the sides with flat. You can see the oiler slot under the round hole, this is where you want to drill. Of course, I used some cobalt bits on a drill press with cutting oil (I happen to use coconut oil as cutting oil, I grow it in my back yard so to speak). Not I have to admit, there are a number of bars I have drilled, and I am "pretty" certain this is one of them. At any rate, you know where to drill the hole, and also when you flip the bar, the adjuster pin will now go in this hole, and the slotted/oblong hole will serve as the oiler hole. Hope this helps.

Lendeth thou not your cherished saws to ruffians, yea verily, thou shalt suffer therefrom woefully and teareth out thine hair in remorse.

What a bummer. Send some photos of your concerns and the forum will chime in with support.

Last edited: