It's alive........

I suppose I just couldn't help myself, but had a little bit of discretionary time tonite. Really all I needed to do for a run test was to install the plug, muffler, stuff some gas in it and give it a pull--who can restrain themselves at that point? After only a few pulls, it fired, so I closed the choke and it literally screams. I put that little "thread protector" on it to extend the reach of the compression release trigger, and that worked fine. As you've likely already guessed, I am still planning to replace that trigger with a new one when I find one. So now it runs, idles, howls up to speed in a very satisfying fashion.

The "thread protectors," I used the white one.

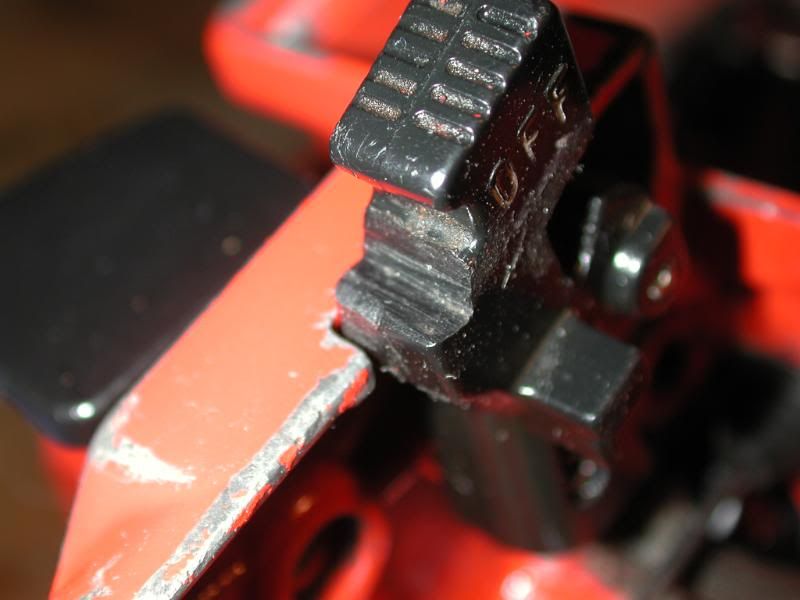

In installing the muffler, I noted that there was a screw hole missing in the side of the cylinder. Orig cylinder on the right, "new" cylinder installed. You can see the missing screw hole bottom center of the pot on the right. I don't think this is a problem, I could drill and tap it out, but now that the saw is running, I will tear it down again to replace the rings, re-install my old cylinder, and put it back together one more time.

Also, on the next assembly, I'll replace the crank seals. I did manage to come up with crank seals for this, part numbers below for those with Ropers that need new seals. I am not certain it really needs them as I did no pressure leak or vacuum test, but I don't think it's a bad idea since I'm doing a rebuild on a more than 40 yr old saw that I want to have around for a long time yet. It was a real pain finding those seals, but once found, now everyone can benefit from the result.

Original Seal on the right.

Of course, I haven't spiked the ball in the end zone after a 100yd kickoff return, but it's a field goal and a few points on the board. It runs, the tank halves don't leak, now I can comfortably pull it all apart again for the rest of what I want to do to it. I'll contact the Greek and buy 2 different sets of rings, and go with what fits best.