Fish

Tree Freak

Sorry, humbaggg, err, humbuggg..

Way back in the beginning of your build thread you mentioned that you gapped the coil @ 0.005".

That should be more like 0.010-0.012".

Surprised no one picked up on that.

Re-gap the coil - use a business card

Gap the plug - 0.020" (try a new one if you have to)

No I have both the IPL and service manual. Always nice how people are here on AS. Thanks for the help though!Do you need a STIHL service manual to help you diagnose?

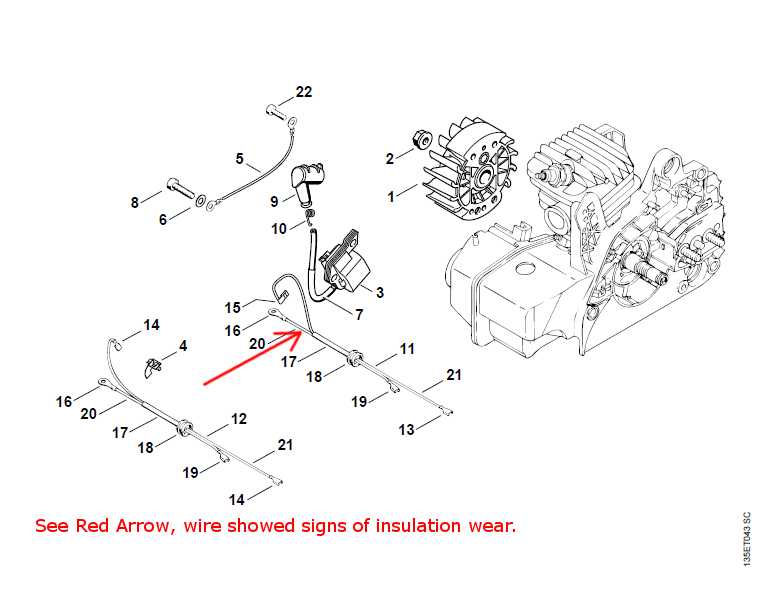

So far you have been the closest to finding the problem. I pulled off the starter and regapped the coil. However, it still had the same problem. So I took the whole saw down to just the jug and bottom tank assembly. My thought was to get the coil out and check it on the ohm meter to see if there was something it was showing, and to get in and inspect the impulse nipples on the jug and handle assembly. Upon inspection of the wiring from the kill switch, I happened to find the insulation worn off the wire. I said to myself pretty much felt this was :confused2: when that little part was causing me all the problems. The kicker is, it was on the backside of the wire so unless I took everything apart (like I did) I would have never seen it. Ugh... I feel that I could tear down this saw and rebuild it in about 30 minuets after I have had it apart so many times.Way back in the beginning of your build thread you mentioned that you gapped the coil @ 0.005".

That should be more like 0.010-0.012".

Surprised no one picked up on that.

Re-gap the coil - use a business card

Gap the plug - 0.020" (try a new one if you have to)

Enter your email address to join: