Had damage similar to this on a MS260, same side (muffler), damage not quite as severe. The saw had a leaky fuel line. The fuel line had actually deteriorated at a low spot where fuel would remain in the line. I replaced piston/cylinder, and all other gas,impulse, oil lines. Saw runs fine now. I would say that air entering the fuel mix from the fuel line hole caused the saw to run lean, thus causing the damage.took my 361 out to do some cutting last week.

Fired up and ran for about 5 mins and then locked up until it cooled down.

First its been ran in about 8 months.

new non ethanol gas / stihl mix.

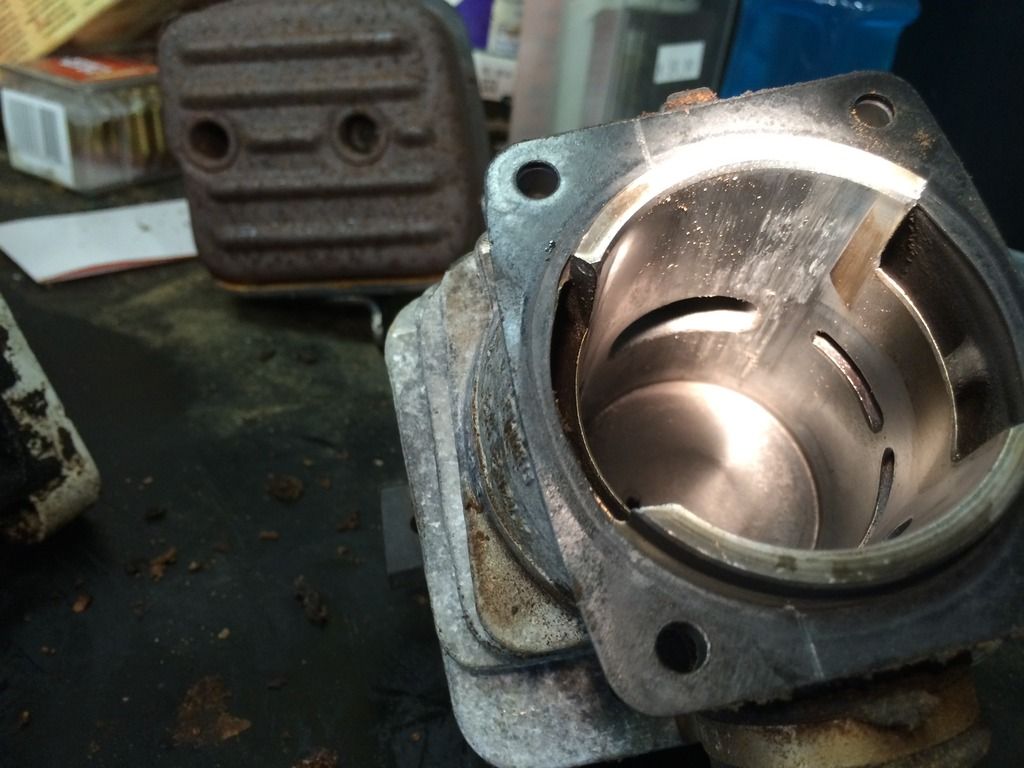

took muffler off and looked and sure enough it was scared up.

Pulled cylinder off and here is what I found

What causes this?

What to check?

New piston / cylinder are in order?

Thanks for the help!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stihl 361 cylinder / piston woes

- Thread starter RuffneckDave

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

drf255

BAD CAD

That piston was installed backwards, BTW.

Ring Locating pins should be located on the intake side OEM. People flip them for performance and porting sometimes.

I must say, I'm not familiar with the 361. Maybe they are on the exhaust side.

Someone phucked with that saw at some point. Putting piston in backwards means the the TOOL that assembled it either knew alot, or nothing.

Anything possible.

Is that a piece of the ring embedded down on the right side of the piston? My guess is the ring caught, snapped, got bounced around, then the part finally found a resting place in that big ass groove on the right.

Ring Locating pins should be located on the intake side OEM. People flip them for performance and porting sometimes.

I must say, I'm not familiar with the 361. Maybe they are on the exhaust side.

Someone phucked with that saw at some point. Putting piston in backwards means the the TOOL that assembled it either knew alot, or nothing.

Anything possible.

Is that a piece of the ring embedded down on the right side of the piston? My guess is the ring caught, snapped, got bounced around, then the part finally found a resting place in that big ass groove on the right.

RuffneckDave

ArboristSite Lurker

Whats the marks in the bottom end last pic, pry bar ?

sorry, I don't see what you see. I took it apart by hand, no prying needed.

That piston was installed backwards, BTW.

Ring Locating pins should be located on the intake side OEM. People flip them for performance and porting sometimes.

I must say, I'm not familiar with the 361. Maybe they are on the exhaust side.

Someone phucked with that saw at some point. Putting piston in backwards means the the TOOL that assembled it either knew alot, or nothing.

Anything possible.

Is that a piece of the ring embedded down on the right side of the piston? My guess is the ring caught, snapped, got bounced around, then the part finally found a resting place in that big ass groove on the right.

Yes, looks embedded. Tat was the only bad section, other side was fine.

RuffneckDave

ArboristSite Lurker

That piston was installed backwards, BTW.

Ring Locating pins should be located on the intake side OEM. People flip them for performance and porting sometimes.

I must say, I'm not familiar with the 361. Maybe they are on the exhaust side.

Someone phucked with that saw at some point. Putting piston in backwards means the the TOOL that assembled it either knew alot, or nothing.

Anything possible.

Is that a piece of the ring embedded down on the right side of the piston? My guess is the ring caught, snapped, got bounced around, then the part finally found a resting place in that big ass groove on the right.

went back and looked at piston. If you were holding the saw by the handle, looking down in the piston the top ring's pin is at 6 o'clock, while the bottom rings pin is at 11 o'clock.

Check the impulse line, intake boot both were good.

the fuel line a one spot looked dry rotted, but i plugged one end and blew in it and couldnt find it leaking.

now what to check?

thanks again for the help.

drf255

BAD CAD

I don't understand. If you're holding the saw if as using it, at least on older stihl models, the ring gaps should be at 530 and 730 ish o'clock. Should be riding near edges of intake port.

Someone that has more experience than I needs to opine about this model.

It's a Quad port. For all I know, still flipped the ring gaps around.

Someone that has more experience than I needs to opine about this model.

It's a Quad port. For all I know, still flipped the ring gaps around.

drf255

BAD CAD

I just checked some eBay pics. It does look like the rings are indeed at 11 and 6 o'clock.

My error.

My error.

Bilge Rat LT 20

ArboristSite Operative

The crank looks real dry.

Not run for 8 months. Should have had a sharp chain on it before starting and the carb tune checked before working with the saw.

Time to clean everything, replace all rubber parts and fully rebuild it. Seals can harden, take a set from sitting then leak. Replace them too.

The 361 is a fine saw, it is worth fixing it right.

Good gas and 40 to 1.

Not run for 8 months. Should have had a sharp chain on it before starting and the carb tune checked before working with the saw.

Time to clean everything, replace all rubber parts and fully rebuild it. Seals can harden, take a set from sitting then leak. Replace them too.

The 361 is a fine saw, it is worth fixing it right.

Good gas and 40 to 1.

RuffneckDave

ArboristSite Lurker

The crank looks real dry.

Not run for 8 months. Should have had a sharp chain on it before starting and the carb tune checked before working with the saw.

Time to clean everything, replace all rubber parts and fully rebuild it. Seals can harden, take a set from sitting then leak. Replace them too.

The 361 is a fine saw, it is worth fixing it right.

Good gas and 40 to 1.

I agree on the sharp chain. But saw wasn't used to cut. just fired up and ran.

I also encourage you to fix the saw. After 700 hours, my 361 keeps running and running and running...

RuffneckDave

ArboristSite Lurker

I also encourage you to fix the saw. After 700 hours, my 361 keeps running and running and running...

I plan on it, how's the Tecomec cylinder/ pistons ?

Your cylinder looks like it could be saved with some careful honing. Think in terms of that while you order a new piston and rings. Check U-Tube for cylinder honing by hand. It really isn't that tough to do with some good high-grit sandpaper and honing liquid.I plan on it, how's the Tecomec cylinder/ pistons ?

RuffneckDave

ArboristSite Lurker

use flex-hone ?

l think blaming the failure on the chain not being sharp is a little ignorant, having a sharp chain is important but l do not believe it responsible. How well did the op 'mix' his fuel and oil? This issue must be correctly diagnosed in order from preventing it again on a new OEM piston cylinder. Replacing affected parts or repairing them may be time/money wasted if it were to occur again.

RuffneckDave

ArboristSite Lurker

I ran the same jug of gas through a pole saw with no problems.

Bilge Rat LT 20

ArboristSite Operative

Look up removing transfer without acid by Mastermind.

It will show how to safely clean the cylinder.

No flexhone.

No wood cutting? Was it just idleing or reving it up?

It will show how to safely clean the cylinder.

No flexhone.

No wood cutting? Was it just idleing or reving it up?

RuffneckDave

ArboristSite Lurker

no wood cutting , just revving up

no wood cutting , just revving up

dave,

"revving up" or PISS REVVING !!!!

(see notes)

(don't worry this is the only place where piss revving is somewhat accepted...

Notes:

piss revving is the insane over revving, screaming your saw to max RPM typically in a locked garage,

for no apparent reason other then being 'neighborly'. Not to be confused with "tuning" a saw.

RuffneckDave

ArboristSite Lurker

Ok, you got me. I wasn't in a garage though!

Ok, you got me. I wasn't in a garage though!

dats OK buddy.....we understand...( we wont tell anyone)

but hard to tall if this one wasn't a "gradual" failure as opposed to a "one catastrophic event" like a bad fuel or an over heated event. test the systems and try to find out the weak links and try to find them all. not just the biggest one.

I like to blow and clean the crap out of the saw before it gets to the bench, then start to pressure test before I remove the top. find the leaks then replace and put it back together then retest for leaks again. I test the new lines and stuff too because Im on my dime and time not a shops. OCD and such being as it is.

RuffneckDave

ArboristSite Lurker

ok, sounds like a plan

whats best way to plug off the intake boot to test?

whats best way to plug off the intake boot to test?

Similar threads

- Replies

- 39

- Views

- 854

Latest posts

-

-

-

-

-

-

Iraq War Veteran trying to use remaing GI Bill after BA in English

- Latest: Guillermo Guzman