I have forced air furnace. This is how it works. You start a fire, when the plenum reaches the set point on the back of the stove both forced air blowers turn on to send warm air to the house. If you set the wall thermostat at say 75 degrees, a small fan kicks on sending air into the firebox thus fanning the fire. When the hse reaches 75 degrees the small fan kicks off. Here is the problem. Even when the hse is 75 and the small fan is off not calling for heat, the other 2 blowers will cycle on and off to try to keep the firebox running in a certain temp range say between 100 and 175 degrees. The fans kick on when the plenum is at 175 degrees then turn off when the plenium drops to 100. What good is the thermostat if the blowers run intermittently to regulate the plennium temps. Eventually the hse is at 80 degrees even with the thermostat set at 75. Also air is being drawn thrue the fan that fires the coals even when it isn't actively running this keeps the fire burning to fast , and we go thrue alot of wood. I ground the tits off the air inlets on the ashdoor so I could completely close the air off to try and compensate for what is being drawn thrue the forced air fan. I can fill the fire box completely with Maple logs (the kind of maple that has the helicopters in the fall) in the evening and even with most of the air shut down and the stovepipe damped down 90% all I have left is hot coals. Seems to burn to fast. Set like this the thermometer shows its burning in the creosote range, which I don't like. The stove is only 1 month old. Can anyone offer help, enlightenment or ideas? Or is this just typical. I wired it up just as the factory recommends. Thanks Steve.. Columbus Ohio:bang:

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

US Stoves Hotblast 1557. Help Information.

- Thread starter kallaste

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

laynes69

Addicted to ArboristSite

Well I should be an expert on these things. I have a 1500 hotblast and you have to realize that if you load it up, the heat has nowhere to go but the house. Your limit control is kicking on the blowers to help put heat in the house and cool the unit. Last night I loaded my wood furnace up with about 5 decent pieces of hardwood, cherry and locust. Did this at about 9:00 pm temps were in the mid 20's woke up at 5:00 am to get ready for work and the house was 77 degrees. We have a large old victorian, which it heats the upstairs and downstairs and helps the basement. There was a good 4 to 6 inch coal bed left over after all night. I have the forced draft and my flapper is wide open and I keep the ash pan damper open 2 1/2 turns to 3 turns. The forced draft isn't really made for mild temps. It will do its job when its gets cold out. Sometimes the wood furnace may not be able to produce enough heat in the middle of the night because the cold is cooling the house faster than its heating, therefore the forced draft kicks on to feed the heat in the home. You'll find it useful in Winter Time. Sounds like your feed door damper isn't closed all of the way. If you shut down all of the air, you'll produce way too much creasote. Whenever you load the wood furnace, crack the ash door for a few minutes, watch not to over fire it. When its burning and starts to charr, you should be able to close the ash door set the damper for 2 to 3 turns open and get secondary combustion. Also if you feed small splits of wood it will burn up fast. Watch your chimney for how its burning it will tell you whats going on. Hope this helps. Forgot to add, whats your control set on to start and stop?

laynes69 said:Well I should be an expert on these things. I have a 1500 hotblast and you have to realize that if you load it up, the heat has nowhere to go but the house. Your limit control is kicking on the blowers to help put heat in the house and cool the unit. Last night I loaded my wood furnace up with about 5 decent pieces of hardwood, cherry and locust. Did this at about 9:00 pm temps were in the mid 20's woke up at 5:00 am to get ready for work and the house was 77 degrees. We have a large old victorian, which it heats the upstairs and downstairs and helps the basement. There was a good 4 to 6 inch coal bed left over after all night. I have the forced draft and my flapper is wide open and I keep the ash pan damper open 2 1/2 turns to 3 turns. The forced draft isn't really made for mild temps. It will do its job when its gets cold out. Sometimes the wood furnace may not be able to produce enough heat in the middle of the night because the cold is cooling the house faster than its heating, therefore the forced draft kicks on to feed the heat in the home. You'll find it useful in Winter Time. Sounds like your feed door damper isn't closed all of the way. If you shut down all of the air, you'll produce way too much creasote. Whenever you load the wood furnace, crack the ash door for a few minutes, watch not to over fire it. When its burning and starts to charr, you should be able to close the ash door set the damper for 2 to 3 turns open and get secondary combustion. Also if you feed small splits of wood it will burn up fast. Watch your chimney for how its burning it will tell you whats going on. Hope this helps. Forgot to add, whats your control set on to start and stop?

I have the limit controls set at 100 150. I will look at adjusting the door and ashdoor this Am to see if it helps. I completely loaded the stove at midnight completely closed the ash door air and slightly cracked the door air adjusment about a 1/4 in. This morning I had 2 softball sized pieces left in the stove. House was 73 before bed, House was 73 this morning. Thermostat was set on about 75.

hautions11

ArboristSite Operative

furnace

I have a similar set up in an older Royal furnace. My firebox blower has an air inlet adjustment that limits air when the blower is not running. I have experienced your situation, when it is not very cold outside. During those times I only burn at night. When the furnace is ideling, my thermometer shows in the ctreosote range as well. No way around that. When it is warm like now, I have no problem getting wood to last. I have an older 3300sq ft 1907 dutch colonial 2 story house. I find my furnace is good to about 5 degrees. Below that I have to get up at 2-3 and feed it.

If you are having trouble getting a fire to last now, it might be your wood. Soft or silver maple is not a real dense wood. I agree with the comment above, split your wood in larger pieces. Small pieces and lots of surface area will burn up a lot faster. I save my oak and hickory for the cloder months.

When it does get cold, I also try to warm the house up in the evening while i am home. What I mean is if the thermostat is normally set to 68-70, over the course of the evening, I turn it up to 74. When I load the furnce for the last time, I turn it back to 68. That definatly helps my wood last all night. I am kind of rambeling, but I hope this helps. Good luck.

I have a similar set up in an older Royal furnace. My firebox blower has an air inlet adjustment that limits air when the blower is not running. I have experienced your situation, when it is not very cold outside. During those times I only burn at night. When the furnace is ideling, my thermometer shows in the ctreosote range as well. No way around that. When it is warm like now, I have no problem getting wood to last. I have an older 3300sq ft 1907 dutch colonial 2 story house. I find my furnace is good to about 5 degrees. Below that I have to get up at 2-3 and feed it.

If you are having trouble getting a fire to last now, it might be your wood. Soft or silver maple is not a real dense wood. I agree with the comment above, split your wood in larger pieces. Small pieces and lots of surface area will burn up a lot faster. I save my oak and hickory for the cloder months.

When it does get cold, I also try to warm the house up in the evening while i am home. What I mean is if the thermostat is normally set to 68-70, over the course of the evening, I turn it up to 74. When I load the furnce for the last time, I turn it back to 68. That definatly helps my wood last all night. I am kind of rambeling, but I hope this helps. Good luck.

laynes69

Addicted to ArboristSite

Try lowering your limit a little I'm set at 140 on and about 80 off. This will take more heat from the furnace. Last night I kept my home at 77 all night. I loaded it at 8:30 and woke up at 3:30 am with 3 full logs still burning. Try some harder wood for nightime. If your getting creasote in milder weather, try burning fewer pieces with more air. I can burn a clean burn in mild weather but I'll burn it hot and fairly fast. If you get your firebox up in temps and get the wood charred before bed, this insulates the wood keeping the gasses from coming out of the wood too soon, and helps keeps temps up in the firebox for a good burn. You'll get it, but like I said installation has alot to do with it. Ever since I reinstalled mine in series I haven't had any problems keeping up with the heat.

EastwoodGang4

ArboristSite Operative

In series?

Laynes69 what do you mean about installed in series? I have a USSC 1557 that is plumbed into the main plenum of my gas furnace.

Laynes69 what do you mean about installed in series? I have a USSC 1557 that is plumbed into the main plenum of my gas furnace.

laynes69

Addicted to ArboristSite

Instead of me having 2 blowers on the wood furnace, I use only the blower on the main (LP Furnace). All air that goes through the system can only go one way. The Limit kicks on the blower only on the main furnace which then removes and distributes the heat throughout the home. It was installed parallel but I changed it and WOW what a difference. I have 3 8 inch ducts going into the furnace and 3 8 inch ducts going out of it. If I had to do it again, I would just run a single 8x20 duct off the LP furnace plenum into the side of the Wood furnace. Then just cap the 2 holes in the back, cut a larger hole in the top and install a full plenum. This works just fine for me though.

EastwoodGang4

ArboristSite Operative

series connection

SWEET i wish i had thought of that before i cut the holes in the plenum of the furnace!!! o well live and learn

SWEET i wish i had thought of that before i cut the holes in the plenum of the furnace!!! o well live and learn

The reason why your wood furnace is over heating is simple

The reason why your wood furnace is over heating is simple, when the draft fan shuts off, the natural draft of your chimney is still pulling air through the fan unit. I have one on my Hotspot and the design is very poor. If you want automatic control, the unit would need to be heavily modified. I gave up on mine and don't use it at all. I would guess you could add a shut off valve, plus the air inlet in the firebox should be redirected to the base of the fire where combustion air is needed which would give better control and having the air come in below the fire instead of above, would also reduce the possibility of pushing smoke out into the house.

I bought my Hotspot wood furnace a few years ago and had nothing but trouble with it, overheating, smoke in the house, tons of soot and cresol in the chimney. But I was able to correct the problems by modifying the furnace. First off, the manufacture obviously doesn't know a thing about how to build a proper wood furnace and has made a number of stupid design mistakes. The good points are that the furnace is solidly built with thick steel plate and is inexpensive to buy. I had to block off the door vent, it was a real smoke leaker, and covered it with a plate with a small hole with a slide cover so I can check the fire without opening the door. I also put a wood stove magnetic thermometer on the front so I can monitor the size of the fire or heat output without opening the door and getting smoke in the house. I also ran a fresh air intake duct, 6 inch diameter, the same size as my chimney, right up to the furnace ash door. Switched to a double walled stove pipe and added a chimney extension for improved draft. Now the biggest problem with wood furnace is the fact that they over heat the house. This is why the better units are boilers, you build a fire and get the water really hot, but the circulating pump only runs when heat is needed. By having a large water capacity, the heat is stored until needed, while a hot air furnace has to dump it into the house to keep from overheating the firebox. So, with a furnace, you need to reduce the fire which makes a lot of soot and cresol. I found the simple solution is to add post combustion air and burn off the soot and cresol while keeping the fire small. I drilled a hole and ran an one and half inch size steel water pipe in through the front of the furnace to the back of the firebox and up the back to under the shelf and then forward to the edge of the shelf. The intake of the pipe has a drop leg running down to almost the floor to keep any smoke from backing out the pipe. Under natural draft with the ash door closed, air is drawn in through the pipe and is preheated by the fire, so when it comes out the end of the pipe it is hot and ignites the unburned gases. This allows you to close down the spin damper and burn a small fire cleanly without messing up your chimney or putting out a ton of black smoke. So now I build a small hot fire, let it get hot enough to turn on the furnace fan, then close the ash door and let the house temperature rise to 70 degrees and spin the damper close. If I haven't put too much wood in the furnace, it will raise the house temperature to 72 and then slowly run out of wood. The post combustion air eliminates most of the cresol and all of the soot, the smoke coming out of the chimney is much less and lighter colored, and soon is invisible as the burn progresses. The trick is also to know how much wood to add, you need to consider the outside temperature and how many degrees you want to raise the house temperature. That way once you are where you want to be, your fire will be down to coals and will not over heat the house. Learn to operate your furnace, for mine at 20 degrees outside, with a large fire and the spin damper closed, I stay even at about 70-72 degrees in the house. A lot depends on how well your house is insulated. The better insulated, the better it will hold the heat and the less you will need to burn and the less smoke you will make. Forget about all that nonsense about loading up the firebox and having long burns, for the Hotspot and probably all hot air furnaces, it is a myth. For even at minimum burn, the house will over heat unless it is very cold outside. The way to keep the house warm for long times is insulation, that will reduce your temperature loss per hour, allowing you to make a small hot fire, heat the house up to 72 and them let it cool down to 68. That is the real secret of operating a wood furnace, only put in as much wood as you need to bring the house up to temperature.

I have also added a catalytic combuster that greatly reduces emissions, but since it increases heat output, I only use it in colder winter weather when you want more heat. Since it will increase the efficiency of your wood furnace by 25 to 30 percent.

The best way of course of reducing emissions is to increase the insulation of your house, then you will need to burn a lot less wood and can go longer between burns, and will save you money even when you are not burning wood since it will also reduce your gas heating bill. Let's face the facts, most wood burning is only a supplemental heating activity, so insulation will probably save more money than the wood furnace will. I use mine full time, so the extra insulation reduces the amount of wood I have to cut, split, stack and burn, by 50 to 75% and allows the heat of a fire in the evening to last until morning (72-65).

The reason why your wood furnace is over heating is simple, when the draft fan shuts off, the natural draft of your chimney is still pulling air through the fan unit. I have one on my Hotspot and the design is very poor. If you want automatic control, the unit would need to be heavily modified. I gave up on mine and don't use it at all. I would guess you could add a shut off valve, plus the air inlet in the firebox should be redirected to the base of the fire where combustion air is needed which would give better control and having the air come in below the fire instead of above, would also reduce the possibility of pushing smoke out into the house.

I bought my Hotspot wood furnace a few years ago and had nothing but trouble with it, overheating, smoke in the house, tons of soot and cresol in the chimney. But I was able to correct the problems by modifying the furnace. First off, the manufacture obviously doesn't know a thing about how to build a proper wood furnace and has made a number of stupid design mistakes. The good points are that the furnace is solidly built with thick steel plate and is inexpensive to buy. I had to block off the door vent, it was a real smoke leaker, and covered it with a plate with a small hole with a slide cover so I can check the fire without opening the door. I also put a wood stove magnetic thermometer on the front so I can monitor the size of the fire or heat output without opening the door and getting smoke in the house. I also ran a fresh air intake duct, 6 inch diameter, the same size as my chimney, right up to the furnace ash door. Switched to a double walled stove pipe and added a chimney extension for improved draft. Now the biggest problem with wood furnace is the fact that they over heat the house. This is why the better units are boilers, you build a fire and get the water really hot, but the circulating pump only runs when heat is needed. By having a large water capacity, the heat is stored until needed, while a hot air furnace has to dump it into the house to keep from overheating the firebox. So, with a furnace, you need to reduce the fire which makes a lot of soot and cresol. I found the simple solution is to add post combustion air and burn off the soot and cresol while keeping the fire small. I drilled a hole and ran an one and half inch size steel water pipe in through the front of the furnace to the back of the firebox and up the back to under the shelf and then forward to the edge of the shelf. The intake of the pipe has a drop leg running down to almost the floor to keep any smoke from backing out the pipe. Under natural draft with the ash door closed, air is drawn in through the pipe and is preheated by the fire, so when it comes out the end of the pipe it is hot and ignites the unburned gases. This allows you to close down the spin damper and burn a small fire cleanly without messing up your chimney or putting out a ton of black smoke. So now I build a small hot fire, let it get hot enough to turn on the furnace fan, then close the ash door and let the house temperature rise to 70 degrees and spin the damper close. If I haven't put too much wood in the furnace, it will raise the house temperature to 72 and then slowly run out of wood. The post combustion air eliminates most of the cresol and all of the soot, the smoke coming out of the chimney is much less and lighter colored, and soon is invisible as the burn progresses. The trick is also to know how much wood to add, you need to consider the outside temperature and how many degrees you want to raise the house temperature. That way once you are where you want to be, your fire will be down to coals and will not over heat the house. Learn to operate your furnace, for mine at 20 degrees outside, with a large fire and the spin damper closed, I stay even at about 70-72 degrees in the house. A lot depends on how well your house is insulated. The better insulated, the better it will hold the heat and the less you will need to burn and the less smoke you will make. Forget about all that nonsense about loading up the firebox and having long burns, for the Hotspot and probably all hot air furnaces, it is a myth. For even at minimum burn, the house will over heat unless it is very cold outside. The way to keep the house warm for long times is insulation, that will reduce your temperature loss per hour, allowing you to make a small hot fire, heat the house up to 72 and them let it cool down to 68. That is the real secret of operating a wood furnace, only put in as much wood as you need to bring the house up to temperature.

I have also added a catalytic combuster that greatly reduces emissions, but since it increases heat output, I only use it in colder winter weather when you want more heat. Since it will increase the efficiency of your wood furnace by 25 to 30 percent.

The best way of course of reducing emissions is to increase the insulation of your house, then you will need to burn a lot less wood and can go longer between burns, and will save you money even when you are not burning wood since it will also reduce your gas heating bill. Let's face the facts, most wood burning is only a supplemental heating activity, so insulation will probably save more money than the wood furnace will. I use mine full time, so the extra insulation reduces the amount of wood I have to cut, split, stack and burn, by 50 to 75% and allows the heat of a fire in the evening to last until morning (72-65).

laynes69

Addicted to ArboristSite

I have never had spillage into the basement at all. You need a strong chimney. I have never had the woodfurnace overfire due to the forced draft. I can have 2 pieces of wood in the woodfurnace, I have the ash pan damper open 2 1/2 turns and I achieve secondary combustion everytime. If I peek into the little holes in the feed door, Dancing Blue flames. They are built to burn just fine, but you need the draft to operate one. With the ash damper open at 2 1/2 turns and the forced air draft open (Not on) I can get a fully clean 8 hour burn. At night the furnace is basically burning up the smoke and slowly burning the wood. It takes alot of trial and error to get it right. You need the oxygen to burn up the smoke and keep the firebox up to temps. Creasote and smoke are not a problem for me at all.

Good trick, but that is a modification

That is a very good trick having the forced draft open but not running (that is a modification since it wasn't designed to run that way), that does give you a source of post combustion air, if you don't have the wood piled too high in the firebox. I considered doing it that way on mine, but decided to run an air pipe so I could locate the air inlet where it wouldn't go into the wood and end up making the fire bigger and the air would be preheated. My concern was that air coming in the forced air inlet would be cold and would tend to drop down into the fire, ( with your stronger draft you are possibly 'pulling' the air across the bottom of the shelf while with the probably smaller draft I have, it may have tended to drop down more into the fire). I am glad your furnace is working well for you and I agree that the Hotspot was designed to work with a tall chimney. I have a one story house with the furnace in the basement, and I have tall trees (60-80') around house which creates down drafts. Every time I would get a down draft, a puff of smoke would come out of the furnace. A well designed wood furnace can handle down drafts with out smoking, once I modified mine, it was no longer a problem. I was just thinking that Hotspot should suggest removing the plug in the forced draft air port to allow it to be used as a secondary air source for post combustion. Otherwise they don't have any provision for it at all, other than what leaks in around the heat controlled damper in the loading door.

That is a very good trick having the forced draft open but not running (that is a modification since it wasn't designed to run that way), that does give you a source of post combustion air, if you don't have the wood piled too high in the firebox. I considered doing it that way on mine, but decided to run an air pipe so I could locate the air inlet where it wouldn't go into the wood and end up making the fire bigger and the air would be preheated. My concern was that air coming in the forced air inlet would be cold and would tend to drop down into the fire, ( with your stronger draft you are possibly 'pulling' the air across the bottom of the shelf while with the probably smaller draft I have, it may have tended to drop down more into the fire). I am glad your furnace is working well for you and I agree that the Hotspot was designed to work with a tall chimney. I have a one story house with the furnace in the basement, and I have tall trees (60-80') around house which creates down drafts. Every time I would get a down draft, a puff of smoke would come out of the furnace. A well designed wood furnace can handle down drafts with out smoking, once I modified mine, it was no longer a problem. I was just thinking that Hotspot should suggest removing the plug in the forced draft air port to allow it to be used as a secondary air source for post combustion. Otherwise they don't have any provision for it at all, other than what leaks in around the heat controlled damper in the loading door.

laynes69

Addicted to ArboristSite

I'll agree with the pipe plug removal on the furnace. I believe thats what gave me the extra air to promote secondary combustion. I am thinking of making some burn tubes that will bolt on the piece of channel in the back of the firebox. Then run under the baffle. This should get enough air to burn off all gasses. I used to shut down the air as much as possible and close the flue damper trying to get a long burn. It would burn much cooler and smoke alot and the house would drop in temp. Even though more air seems like it would burn the wood faster, it helps keep the firebox up to temps and burn off the gasses. And the thing is I get the same burntimes, a clean chimney and probably twice as much heat. Im happy.

hautions11

ArboristSite Operative

WMScott. Do you have any pics? I just posted the secondairy burn question here a few days ago, but I didn't get any response. Your pipe idea sounds like something I had envisioned. At work we build turbine engine parts and I have access to all kinds of Inconel and other high temp materials. I was thinking of a corrigated baffle in stainlees mounted to the bottom of my current baffle. A series of holes in the corregations. See pic.

Feeding the baffle with a pipe through the front of the stove and inside the current baffle area to gather heat.

Do you control the volume of air in your secondairy burn?

I get a little smoke in the house if I peak at the fire too much. I can often crack the door a little, let the fire kick up and release little to no smoke. I have and old 1902 house without much insullation. I rarely have the overheat the house problem. I would appreciate any input you could give.

Larry

Feeding the baffle with a pipe through the front of the stove and inside the current baffle area to gather heat.

Do you control the volume of air in your secondairy burn?

I get a little smoke in the house if I peak at the fire too much. I can often crack the door a little, let the fire kick up and release little to no smoke. I have and old 1902 house without much insullation. I rarely have the overheat the house problem. I would appreciate any input you could give.

Larry

Dear Hautions11

Yes I have pictures, but don't have a clue how to go about posting them on this board, I am new here. Impressive picture by the way, looks like a nice design as it is. Sounds like you are way beyond me in high tech. I just used one and half size galvanized water pipe, the flow of air coming in keeps the pipe from over heating, and it is unlikely that the firebox would ever get hot enough to be a problem. I have used it for over a year and it has worked very well. The air volume is controlled by the inside cross-section of the pipe being about 20% of the intake area of the spin damper in the ash door, which on my furnace is the only place air can come in, I am using only natural draft. So with the damper wide open I have 20% post combustion air which is idea, as I close the damper, I undoubtably have an excess of post combustion air, but the system works well enough. I would rather have a bit too much rather than too little post combustion air to keep the chimney clean. I also have a catalytic combuster just above the outlet of pipe, and putting preheated fresh air in just in front of the combustor works very well. I have the shelf rigged so it slides back and forth with a pull handle that comes out through the front of the furnace above the loading door. I pull the shelf forward to bypass the catalytic combuster until above 400 degrees, then I slide it back into place for operation. Other than occasional plugging, it works great. By using a combination of post combustion air with a catalytic combuster, I like to think I have a hot air wood furnace that is better than anything on the market. Probably not true, but I like to think it.

I also highly recommend that you blow cellulose insulation in your walls and attic and seal the drafts. You should be able to cut your heating needs by well over 75%. Many home building stores sell cellulose insulation and if you buy enough, the rental of the blower is free. I blew my outside walls by drilling 1 inch diameter holes, two per space, one near the top and one towards the bottom and filled the walls. I have wood siding, so I cut pieces of dowels and glued them in place to plug the holes, tapped them back just a bit and leveled with spackle. Really have to look to see where the holes were. Blowing the attic is of course a piece of cake, and since heat rises, it makes a huge difference. You should look into it, it would be very much worth it.

Yes I have pictures, but don't have a clue how to go about posting them on this board, I am new here. Impressive picture by the way, looks like a nice design as it is. Sounds like you are way beyond me in high tech. I just used one and half size galvanized water pipe, the flow of air coming in keeps the pipe from over heating, and it is unlikely that the firebox would ever get hot enough to be a problem. I have used it for over a year and it has worked very well. The air volume is controlled by the inside cross-section of the pipe being about 20% of the intake area of the spin damper in the ash door, which on my furnace is the only place air can come in, I am using only natural draft. So with the damper wide open I have 20% post combustion air which is idea, as I close the damper, I undoubtably have an excess of post combustion air, but the system works well enough. I would rather have a bit too much rather than too little post combustion air to keep the chimney clean. I also have a catalytic combuster just above the outlet of pipe, and putting preheated fresh air in just in front of the combustor works very well. I have the shelf rigged so it slides back and forth with a pull handle that comes out through the front of the furnace above the loading door. I pull the shelf forward to bypass the catalytic combuster until above 400 degrees, then I slide it back into place for operation. Other than occasional plugging, it works great. By using a combination of post combustion air with a catalytic combuster, I like to think I have a hot air wood furnace that is better than anything on the market. Probably not true, but I like to think it.

I also highly recommend that you blow cellulose insulation in your walls and attic and seal the drafts. You should be able to cut your heating needs by well over 75%. Many home building stores sell cellulose insulation and if you buy enough, the rental of the blower is free. I blew my outside walls by drilling 1 inch diameter holes, two per space, one near the top and one towards the bottom and filled the walls. I have wood siding, so I cut pieces of dowels and glued them in place to plug the holes, tapped them back just a bit and leveled with spackle. Really have to look to see where the holes were. Blowing the attic is of course a piece of cake, and since heat rises, it makes a huge difference. You should look into it, it would be very much worth it.

hautions11

ArboristSite Operative

Thanks for the detailed input. To post pictures it is pretty easy. Take your current pics and post them on one of the free services like Photobucket.com.

It is free and you set up an account and post any pics or video there. Once you put photo's there you will notice the yellow tab above in the tool bar of the post area. Copy the top URL listed under the picture in photobucket and paste it in the area that displays when you push the yellow insert link button above. There are other methods as well, but that one works for me. Another option is just email them to me. [email protected].

I am facinated by your ideas, but I do not understande where your catalytic converter is located. My furnace has a handle in the front that allows smoke to go directly up the flue or when it is closed the smoke has to travel to the front area enter tne baffle and then go up the flue. Is your converter round? If a converter would fit in my baffle area I believe it would work. When the bypass is open no converter and when it is closed the smoke would have to travel through the converter. Great ideas, I would love to see some pics.

Thanks for the input.

Larry

It is free and you set up an account and post any pics or video there. Once you put photo's there you will notice the yellow tab above in the tool bar of the post area. Copy the top URL listed under the picture in photobucket and paste it in the area that displays when you push the yellow insert link button above. There are other methods as well, but that one works for me. Another option is just email them to me. [email protected].

I am facinated by your ideas, but I do not understande where your catalytic converter is located. My furnace has a handle in the front that allows smoke to go directly up the flue or when it is closed the smoke has to travel to the front area enter tne baffle and then go up the flue. Is your converter round? If a converter would fit in my baffle area I believe it would work. When the bypass is open no converter and when it is closed the smoke would have to travel through the converter. Great ideas, I would love to see some pics.

Thanks for the input.

Larry

Dear Hautions11

I think I have the picture posting worked out, we'll see if it works. Now my catalytic combuster is mounted in a plate attached to the front edge of the smoke shelf. I modified the formerly fixed shelf, to slide back and forth, since you already have a working bypass, you should be able to just attach a plate to your shelf or sliding baffel plate. Just take a piece of cardboard and trim it to fit in place on the front edge. Then use the cardboard as a pattern to cut a piece of plate steel or thick sheetmetal to hold the catalytic combuster. I used a sheet metal 'spring' mount, set up so the combuster is easily removible for cleaning or firing without it in place. The best place to go for catalytic combusters is stovecombustors.com, cheap and they work very well. I have a 6 inch round one, you need one equal to the crossectional area of your flue pipe. If space is tight a long rectangular one maybe what you will need to fit.

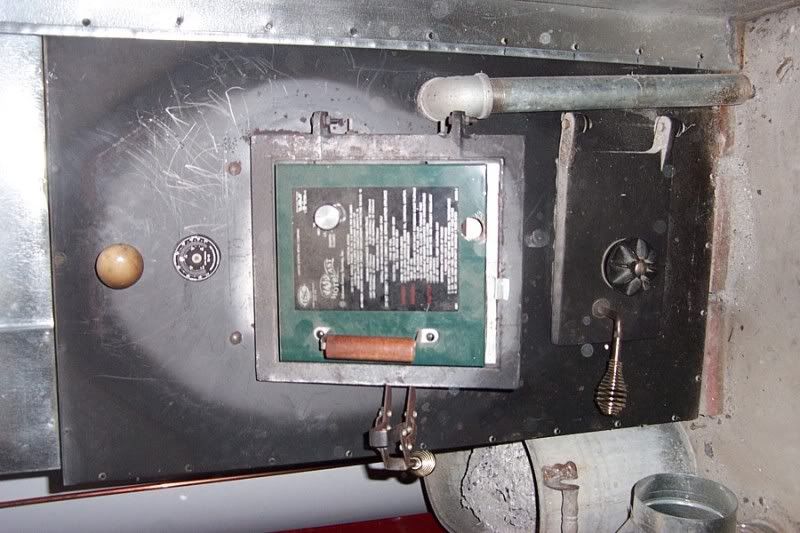

If this works, here is a picture of the front of my Hotspot furnace showing the post combustion air pipe on the lower right and the pull handle above the loading door. The picture is laying on its side and should have been rotated clockwise 90 degrees.

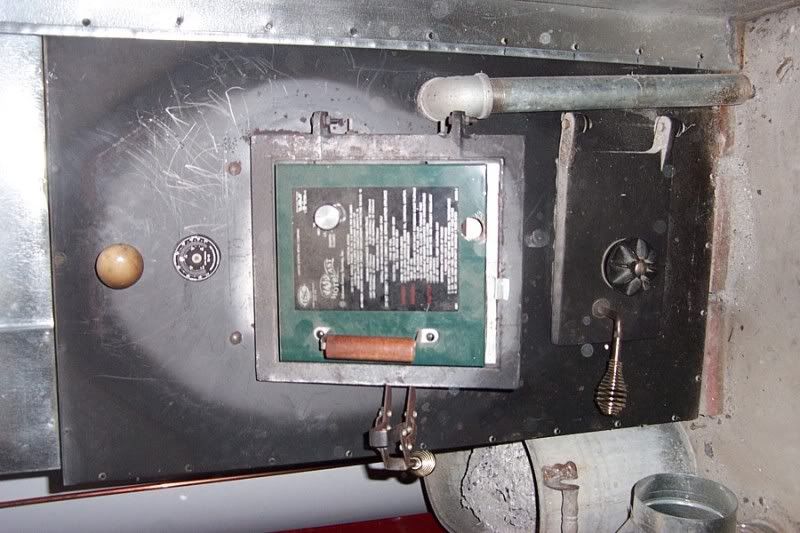

Here is a shot inside the firebox showing the routing of the post combustion air pipe, the long length allows the fire to preheat the air which comes out the end of the pipe just below the mounting for the catalytic combuster which is not installed in this picture. The combustor slides into the bracket which is mounted on the wall I added to the edge of the shelf.

I hope the pictures make sense, I have found this a good combination and far better than the way the furnace worked when I got it. If you look close at the above picture, you can see that the shelf is sitting on angle iron laying on top of the original supports. I just flipped the two shelf pieces over and bolted them together, and then attached the new front piece for the combuster. The pull rod attaches to the front piece just above the mounting for the combuster. I had to build the whole thing outside the furnace and then take it apart and put it back together inside the firebox, it was like building a ship in a bottle.

Sincerely Yours; Wm Scott Anderson

I think I have the picture posting worked out, we'll see if it works. Now my catalytic combuster is mounted in a plate attached to the front edge of the smoke shelf. I modified the formerly fixed shelf, to slide back and forth, since you already have a working bypass, you should be able to just attach a plate to your shelf or sliding baffel plate. Just take a piece of cardboard and trim it to fit in place on the front edge. Then use the cardboard as a pattern to cut a piece of plate steel or thick sheetmetal to hold the catalytic combuster. I used a sheet metal 'spring' mount, set up so the combuster is easily removible for cleaning or firing without it in place. The best place to go for catalytic combusters is stovecombustors.com, cheap and they work very well. I have a 6 inch round one, you need one equal to the crossectional area of your flue pipe. If space is tight a long rectangular one maybe what you will need to fit.

If this works, here is a picture of the front of my Hotspot furnace showing the post combustion air pipe on the lower right and the pull handle above the loading door. The picture is laying on its side and should have been rotated clockwise 90 degrees.

Here is a shot inside the firebox showing the routing of the post combustion air pipe, the long length allows the fire to preheat the air which comes out the end of the pipe just below the mounting for the catalytic combuster which is not installed in this picture. The combustor slides into the bracket which is mounted on the wall I added to the edge of the shelf.

I hope the pictures make sense, I have found this a good combination and far better than the way the furnace worked when I got it. If you look close at the above picture, you can see that the shelf is sitting on angle iron laying on top of the original supports. I just flipped the two shelf pieces over and bolted them together, and then attached the new front piece for the combuster. The pull rod attaches to the front piece just above the mounting for the combuster. I had to build the whole thing outside the furnace and then take it apart and put it back together inside the firebox, it was like building a ship in a bottle.

Sincerely Yours; Wm Scott Anderson

hautions11

ArboristSite Operative

Those are perfect views. Is your theory the secondairy production air is mainly feeding the catalytic combustor? If the combustor is not there, do you feel you get some sec. combustion anyway? If there were holes in you tube it may distribute the air better? It looks like a nice simple set-up and your ingenuity is to be commended! Thanks for the detail info.

the idea is to provide a 'flame spot'

Dear Hautions11

There are no holes in the tube, the idea is to provide a 'flame spot' that stays lit and burns off the gases. The catalytic combuster increases the amount of gases burned, for without I would need 1000 degrees F while with it I only need 400 degrees. I seldom have the top of the firebox that hot, so even with the post combustion air, I am not burning all the gases off. But even without it, I will still burn some or most and will at least get ride of the soot. I have looked in through the peep hole and have seen a flame dancing on the end of the pipe above a smokey fire and have seen the smoke go from dark grey to nearly white when I use the post combustion air. So it works very well if not perfectly and is child's play to add to furnaces that use natural draft. Those smokey outdoor boilers could sure use it, even if they have a powered draft for some smoke would just blow back out of the pipe and being outside that probably wouldn't be a problem. The catalytic combuster really improves it, but adds problems of plugging and to much heat, since if the top of the firebox drops below 400 degrees before the creosote is burned off, the combustor can become plugged and chokes the fire. The furnace needs to be running fairly hot to stay above 400, so any low setting and the logs roll apart and the fire goes cold and then the thing plugs up. So if I am leaving, I need to leave the furnace running nearly wide open or I run the risk of coming home to a cold house. Which is why I leave it out except for the really cold weather.

Sincerely Yours; Wm Scott Anderson

Dear Hautions11

There are no holes in the tube, the idea is to provide a 'flame spot' that stays lit and burns off the gases. The catalytic combuster increases the amount of gases burned, for without I would need 1000 degrees F while with it I only need 400 degrees. I seldom have the top of the firebox that hot, so even with the post combustion air, I am not burning all the gases off. But even without it, I will still burn some or most and will at least get ride of the soot. I have looked in through the peep hole and have seen a flame dancing on the end of the pipe above a smokey fire and have seen the smoke go from dark grey to nearly white when I use the post combustion air. So it works very well if not perfectly and is child's play to add to furnaces that use natural draft. Those smokey outdoor boilers could sure use it, even if they have a powered draft for some smoke would just blow back out of the pipe and being outside that probably wouldn't be a problem. The catalytic combuster really improves it, but adds problems of plugging and to much heat, since if the top of the firebox drops below 400 degrees before the creosote is burned off, the combustor can become plugged and chokes the fire. The furnace needs to be running fairly hot to stay above 400, so any low setting and the logs roll apart and the fire goes cold and then the thing plugs up. So if I am leaving, I need to leave the furnace running nearly wide open or I run the risk of coming home to a cold house. Which is why I leave it out except for the really cold weather.

Sincerely Yours; Wm Scott Anderson

Hot Blast Furnace

I got my Hot Blast a year ago. My Fiance installed it and well now he left so I am trying to figure it out on my own. I keep getting smoke through the loading door vent after i fill and cut back the dampner. Am I doing something wrong? I just had the chimney sweeped. Please any help would be appreciated. It is a Hot Blast 1557 M.

I got my Hot Blast a year ago. My Fiance installed it and well now he left so I am trying to figure it out on my own. I keep getting smoke through the loading door vent after i fill and cut back the dampner. Am I doing something wrong? I just had the chimney sweeped. Please any help would be appreciated. It is a Hot Blast 1557 M.

Last edited:

Similar threads

- Replies

- 5

- Views

- 1K

- Replies

- 4

- Views

- 987

- Replies

- 33

- Views

- 5K

- Replies

- 3

- Views

- 2K

- Replies

- 155

- Views

- 6K