I remember visiting an equipment fair in Hannover a few years back. A dutch manuafacterer was demonstrating a multiple boring unit for drilling holes in I beams, with the security doors open. As buystanders watched the demo, including myself, something hit me straight on the nose. Turned out ot be a hot sharp chip that left me with a bleeding wound. Machine was shut down immediately and the dutch owner begged me not to report it to fair security for the risk of getting banned from the fair. Can't imagine if that chip had hit somebody in the eye....

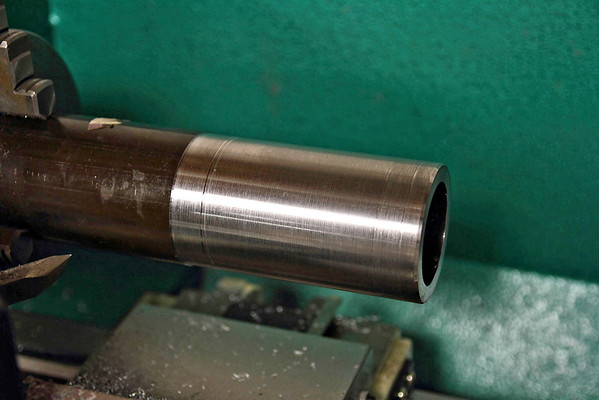

At Westec one year a lathe demo. .5 DOC .060 feed.

Perfect freemachining stuff of course.

But sounded like a 50 cal on the cabinet!!

Got everybody's attention!!