You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What's on your bench

- Thread starter chainsaw _ crazy

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

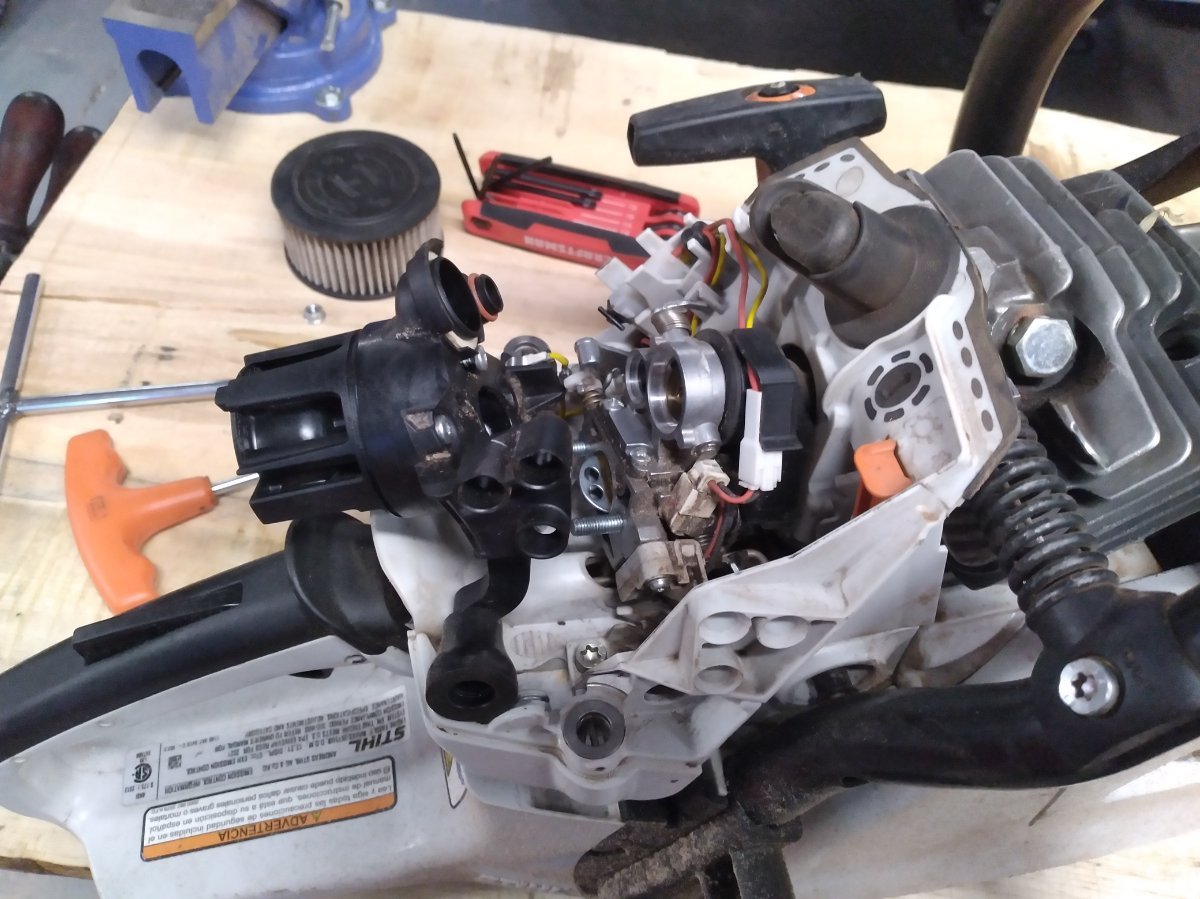

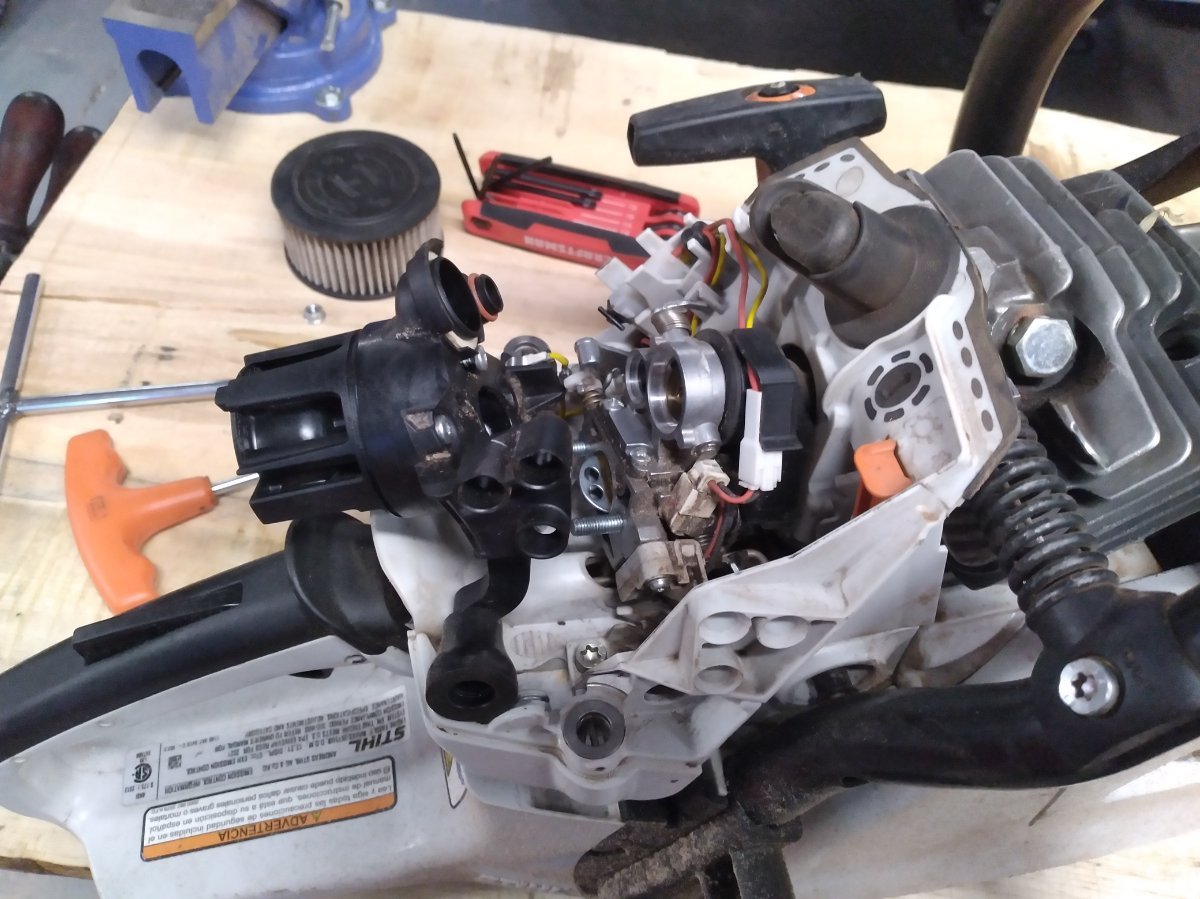

Surprisingly that ms500i was only 260 bucks in parts and 30 mins labor to replace everything and have it back up and running! Not bad for falling from 40ft

link

Gone fishing

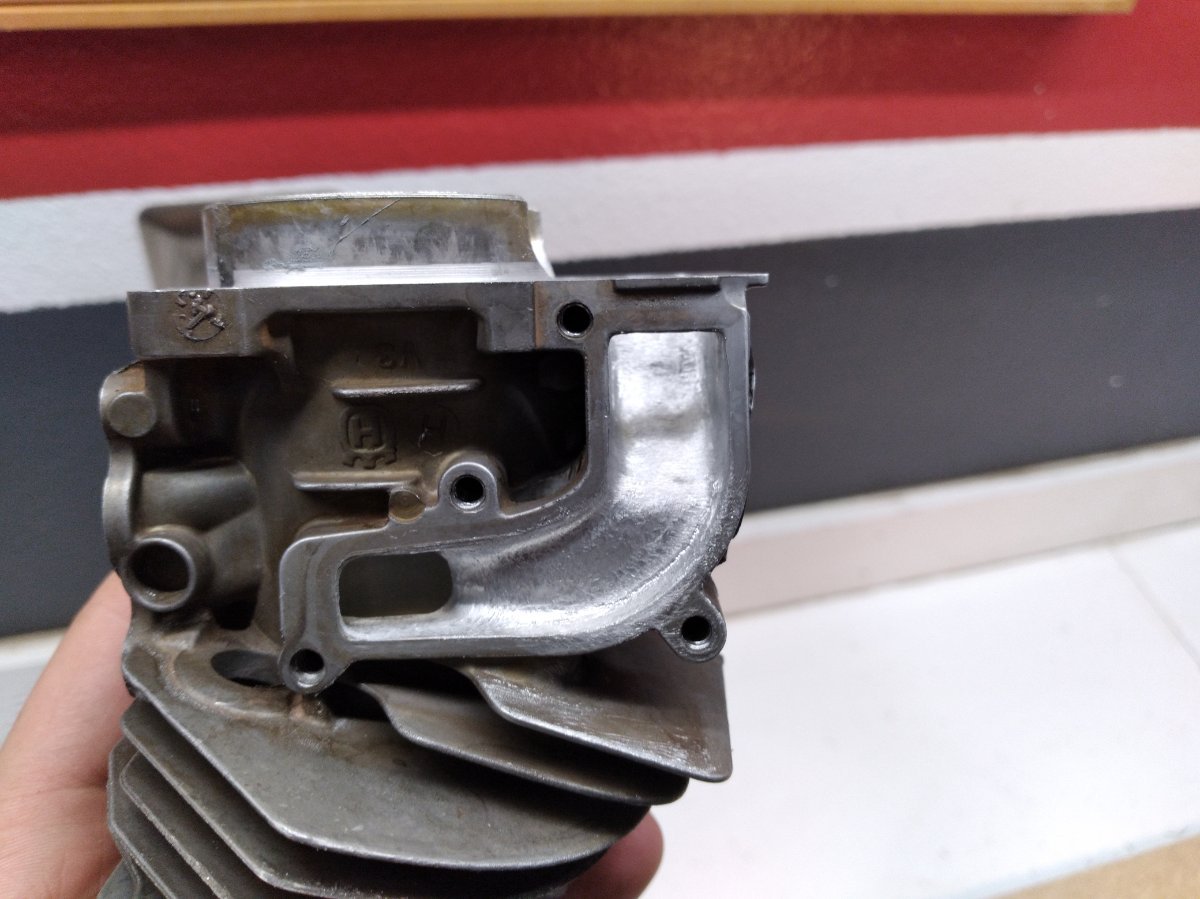

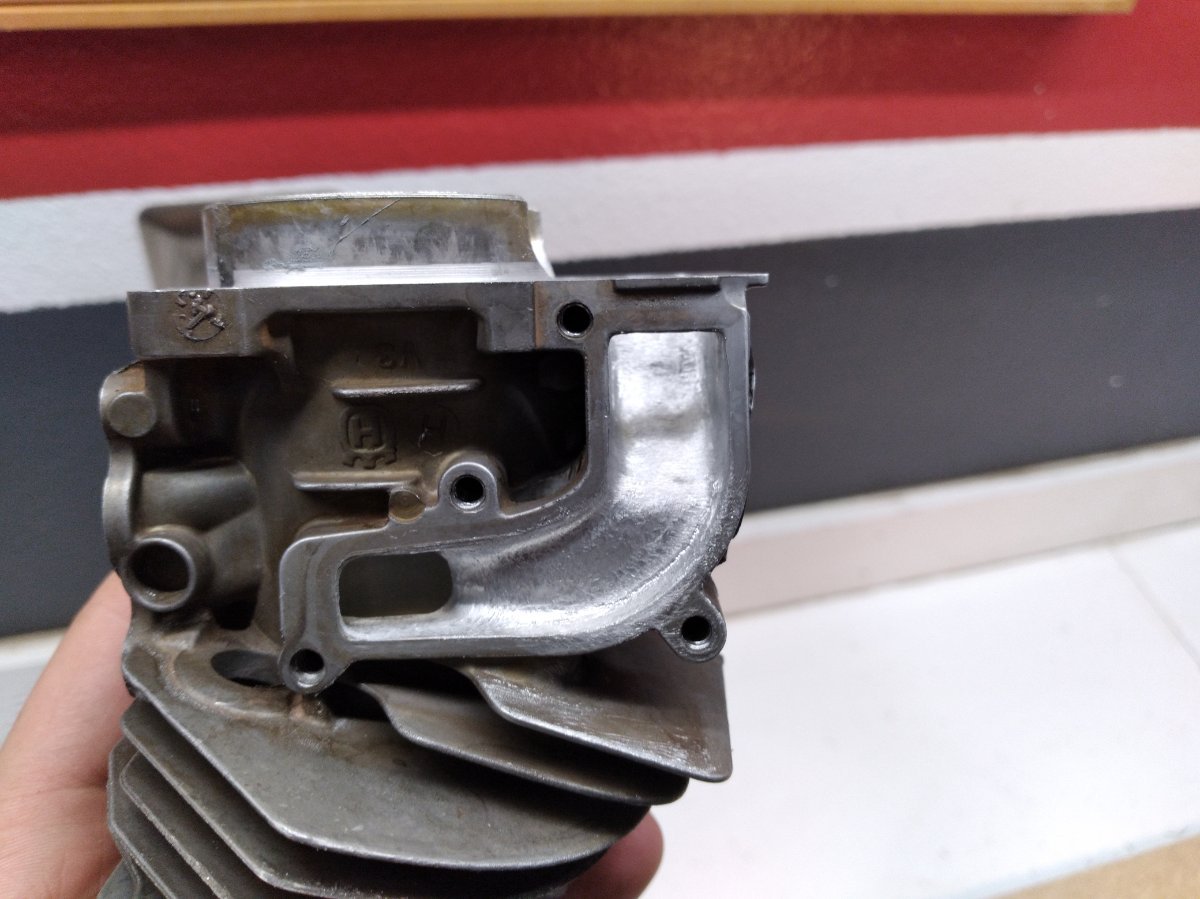

So I have a spacer down beneath the piston so that it is exactly at the position where the transfer ports open, and I have locked it with some tape as well. Just trying to make the transition from the crankcase to the ports a little easier.

Rounding off the bevel...

Beveled and polished the edge at the inside of the cylinder.

Compare...

Poor pics but they are suppose to show the intake adjusted to fit the intake boot, and the exhaust adjusted to fit the muffler/gasket opening.

A little difficult to see but I have beveled/slightly rounded the upper edge at the piston rings about slightly less than 1/2" at the center of the exhaust port, the exhaust port opening is quite flat and a little wider too so I'm just trying to prevent the ring from catching the port edge at the up stroke. I use a black marker pen to see where I'm grinding/polishing, I have ofcourse beveled the exhaust port edge a little too.

Rounding off the bevel...

Beveled and polished the edge at the inside of the cylinder.

Compare...

Poor pics but they are suppose to show the intake adjusted to fit the intake boot, and the exhaust adjusted to fit the muffler/gasket opening.

A little difficult to see but I have beveled/slightly rounded the upper edge at the piston rings about slightly less than 1/2" at the center of the exhaust port, the exhaust port opening is quite flat and a little wider too so I'm just trying to prevent the ring from catching the port edge at the up stroke. I use a black marker pen to see where I'm grinding/polishing, I have ofcourse beveled the exhaust port edge a little too.

A trio of Poulans.

A couple of mild things and a pro 310. The 310 surprised me with how light it is, 10.5 lbs for the power head. Pretty light for a 50 cc saw.

The things are not impressive at all, overweight at 11lbs+ for a 40 CC saw.

Both types are fairly easy to work on, but both suffer from poor muffler designs.

The 310 muffler. Decent flowing, but with the outlet set too far back. You can see the results of this here.

Completely toasted The chain break handle.

The wild things muffler had to have been designed with minimum noise in mind for Joe homeowner. A pathetically small exit that faces the back, requiring extensive shielding to redirect the exhaust flow. This adds a pound of weight to the saw, the ridiculous muffler's almost 3/4 of it.

The wild things both have scored pistons and cylinders, maybe when there's nothing else to do, a cheap Chinese piston/cylinder kit will go on one.

The 310 came in because it stopped oiling, here's why.

Sisel twine and oilers do not mix. The twine jammed up the oiler solid and destroyed the driven gear. The piston and cylinder are in really good shape on the 310. A few other things need replacing like the chain brake handle and the clutch drum, but it'll get going again.

A couple of mild things and a pro 310. The 310 surprised me with how light it is, 10.5 lbs for the power head. Pretty light for a 50 cc saw.

The things are not impressive at all, overweight at 11lbs+ for a 40 CC saw.

Both types are fairly easy to work on, but both suffer from poor muffler designs.

The 310 muffler. Decent flowing, but with the outlet set too far back. You can see the results of this here.

Completely toasted The chain break handle.

The wild things muffler had to have been designed with minimum noise in mind for Joe homeowner. A pathetically small exit that faces the back, requiring extensive shielding to redirect the exhaust flow. This adds a pound of weight to the saw, the ridiculous muffler's almost 3/4 of it.

The wild things both have scored pistons and cylinders, maybe when there's nothing else to do, a cheap Chinese piston/cylinder kit will go on one.

The 310 came in because it stopped oiling, here's why.

Sisel twine and oilers do not mix. The twine jammed up the oiler solid and destroyed the driven gear. The piston and cylinder are in really good shape on the 310. A few other things need replacing like the chain brake handle and the clutch drum, but it'll get going again.

Sierra_rider

Piss revver

Proof I'm not just a Stihlophile...my mk1 550xp is on the bench right now. I did the tear down tonight and measured the numbers. It's going onto the lathe to deck the cylinder and tighten up the squish. I'm considering putting a taper on the piston and the squish band as well...I've had good luck with tapered and domed pistons, so I try to go that route when I can. Finally some port work to finish it off. I'm going to try and be somewhat conservative on compressio with it...these early mk1s had issues with heat, so I don't want to exacerbate the problem any.

I'm also waiting on a piston for it. The stock piston had a surprising amount of wear for how low hours this saw is. I'm just doing an aftermarket piston in this saw...OEM is pricey and I honestly don't like this saw enough to put that much money into it.

I'm also waiting on a piston for it. The stock piston had a surprising amount of wear for how low hours this saw is. I'm just doing an aftermarket piston in this saw...OEM is pricey and I honestly don't like this saw enough to put that much money into it.

Sierra_rider

Piss revver

Got the porting and machine work done on the 550 tonight. I didn't do anything too exotic to the combustion chamber, I actually didn't even touch that...the 550 has a large gap in between the head and the top of the plating, and I'm flirting with the ring falling into that groove with just the .022" I decked the cylinder.

Lotsa grinding on the transfers, some widening and almost a polish on the exhaust. Only really minor stuff on the intake and stratos, I don't want to screw that up. I have a feeling this saw is going to be a strong little runner. Now I'm just waiting on parts to put it together.

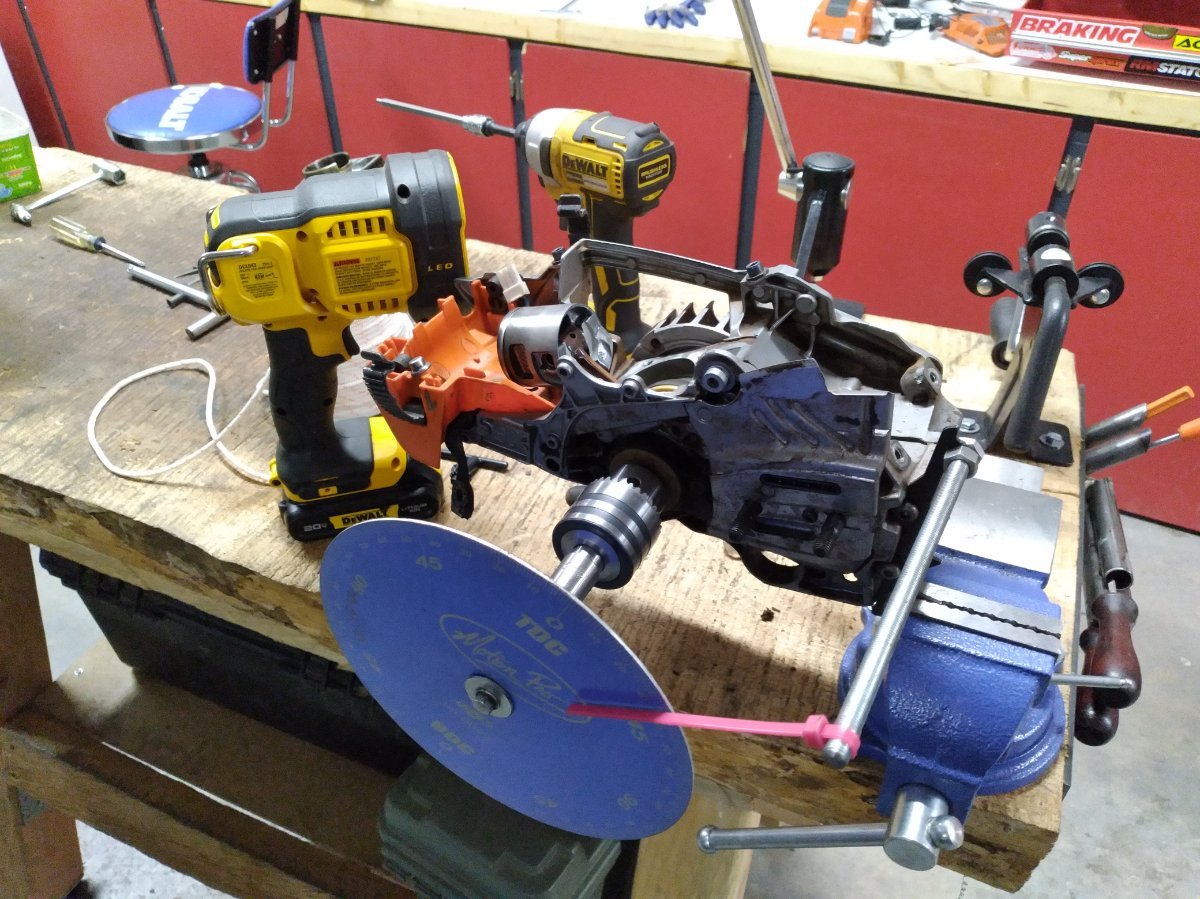

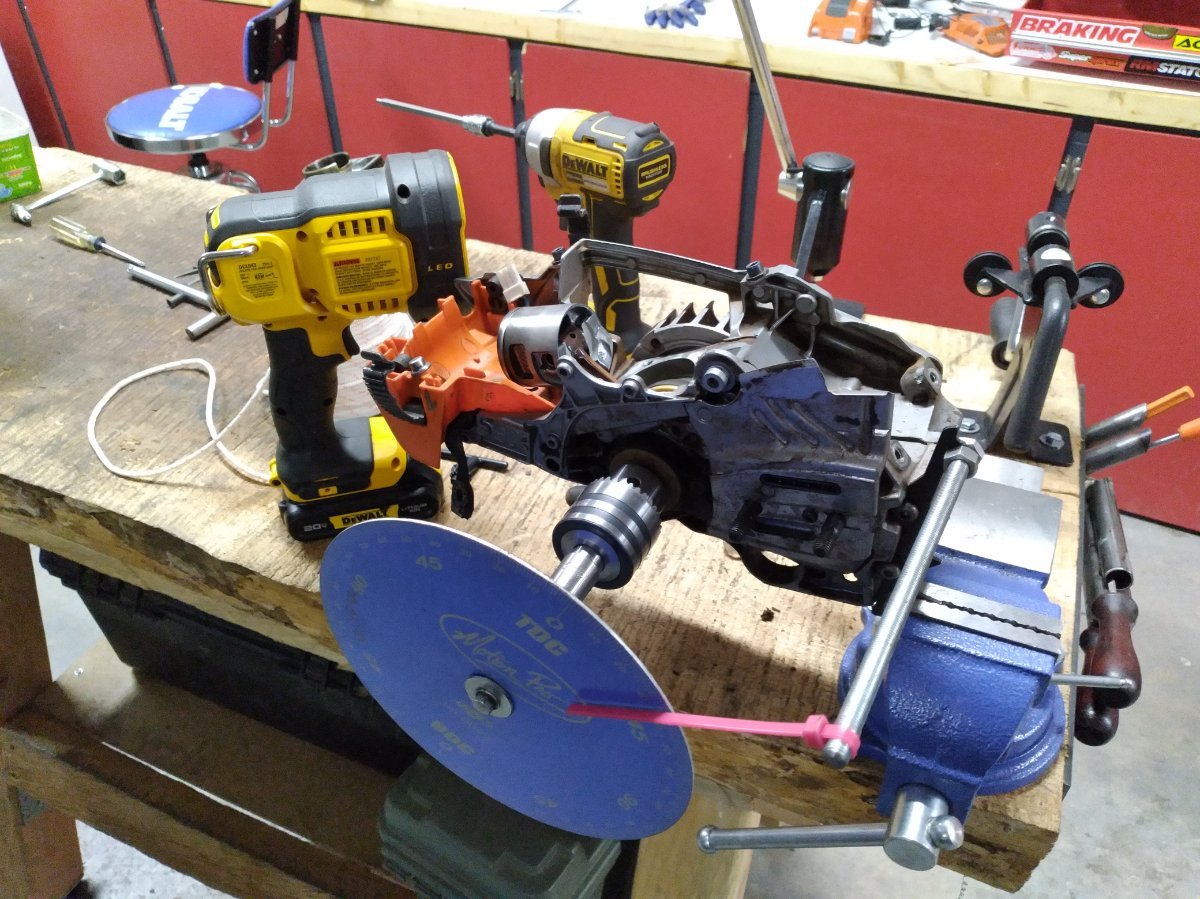

These new-fangled angled cylinders require work on the outside just to machine the rest of it lol:

Porting:

Lotsa grinding on the transfers, some widening and almost a polish on the exhaust. Only really minor stuff on the intake and stratos, I don't want to screw that up. I have a feeling this saw is going to be a strong little runner. Now I'm just waiting on parts to put it together.

These new-fangled angled cylinders require work on the outside just to machine the rest of it lol:

Porting:

Well mine was a much more simple project. Fella at work hadn't used his saw ( husky 500 x torq) in 3 years and just wanted me to " look it over" before he goes to cut this weekend.

For once it was a decent experience. Pretty clean over all with just normal use dirt. Both tanks super clean. He clearly stays up on his air filter, nothing to do there. Bar has never been hot. Angle on both sets of teeth look good and already farily sharp.

Really the only thing I could find to do was to clean out between the rails of the bar but even that crud was minimal.

Still wandering why he had me look at it. From what I saw , he knows how to keep a saw up. She fired on the 4 the pull, idled and revved fine.

For once it was a decent experience. Pretty clean over all with just normal use dirt. Both tanks super clean. He clearly stays up on his air filter, nothing to do there. Bar has never been hot. Angle on both sets of teeth look good and already farily sharp.

Really the only thing I could find to do was to clean out between the rails of the bar but even that crud was minimal.

Still wandering why he had me look at it. From what I saw , he knows how to keep a saw up. She fired on the 4 the pull, idled and revved fine.

Piotr Pakuła

ArboristSite Guru

He wanted to avoid surprises at the logging site and did not want to check it at home ;-)

Could be. He's a super nice fella and is aware of some excessive expenses we've had recently. I wouldn't be surprised if he's just finding work to send my way to stick money in my pocket.He wanted to avoid surprises at the logging site and did not want to check it at home ;-)

link

Gone fishing

A little heavy for my usual firewood processing, but I do like it a lot.

52mm cylinder at 76,5cc with no base gasket and a popup piston, even though not run in and a tad too rich on the fuel blend it actually reminds me of the Dolmar 7910 in power and torque.

I don't use the tac, no point in doing that. I would only need to re-adjust it when in the wood to get it perfect anyway.

Now it only needs some silver colored stickers and engraving the serial ID plate with my name on it.

I was a little worried about the oil pump, because it had only used a 1/5 or so from the oil tank when the fuel tank was like half empty. Then I realized - no problems with the oil pump at all, it's just very very thirsty...

52mm cylinder at 76,5cc with no base gasket and a popup piston, even though not run in and a tad too rich on the fuel blend it actually reminds me of the Dolmar 7910 in power and torque.

I don't use the tac, no point in doing that. I would only need to re-adjust it when in the wood to get it perfect anyway.

Now it only needs some silver colored stickers and engraving the serial ID plate with my name on it.

I was a little worried about the oil pump, because it had only used a 1/5 or so from the oil tank when the fuel tank was like half empty. Then I realized - no problems with the oil pump at all, it's just very very thirsty...

The Poulan 310 is finished, new oiler and a clutch drum/sprocket. Still needs a new bar and chain but the old one's back on for now.

The guts on the chain brake were not salvageable, so it got the chain brake delete treatment. Very light for a 50CC saw, power head is only 9.9 lb without that chain brake, 10.4 with, very close to a ms250 Stihl. Lots of compression and a small recoil pulley makes this saw pretty hard to pull over, but it starts quickly and runs great.

The guts on the chain brake were not salvageable, so it got the chain brake delete treatment. Very light for a 50CC saw, power head is only 9.9 lb without that chain brake, 10.4 with, very close to a ms250 Stihl. Lots of compression and a small recoil pulley makes this saw pretty hard to pull over, but it starts quickly and runs great.

Sierra_rider

Piss revver

Pretty minor work in the shop tonight, just bolt-on improvements to a couple of my work saws. The 400 got a foam air filter. The 500i got a max-flow foam filter and a WCS clutch cover. The clutch cover is pricey and some people talk crap about it, but the stock 500i clutch cover is a piss-poor design for a falling saw.

400:

500:

400:

500:

Piotr Pakuła

ArboristSite Guru

and what is the difference between the two covers? 500iPretty minor work in the shop tonight, just bolt-on improvements to a couple of my work saws. The 400 got a foam air filter. The 500i got a max-flow foam filter and a WCS clutch cover. The clutch cover is pricey and some people talk crap about it, but the stock 500i clutch cover is a piss-poor design for a falling saw

Two on the bench at the moment.

Stihl 170 that needs a fuel line and then we will see what else once it's running.

A micro xxv I talked myself in to messing with. It's got a deep clean , new line and filter and the carb redone minus the metering diaphragm that was missing from the kit.

It sure was a let down to be that close to done on that one and find out you were shorted a part. Both little ones are just being fixed to sell.

Bigger saw coming up. My pm 850 is way past due for a good service. It's been rode hard and put away wet several times in row. That thing can take a beating I'll tell you.

Stihl 170 that needs a fuel line and then we will see what else once it's running.

A micro xxv I talked myself in to messing with. It's got a deep clean , new line and filter and the carb redone minus the metering diaphragm that was missing from the kit.

It sure was a let down to be that close to done on that one and find out you were shorted a part. Both little ones are just being fixed to sell.

Bigger saw coming up. My pm 850 is way past due for a good service. It's been rode hard and put away wet several times in row. That thing can take a beating I'll tell you.

Currently an 028 av that been a pain in the neck. But it jjst needing an impluse line hopefully then we will see if it wants to run.

And my 036 pro that just got all cleaned up for the first time since i inherited it. Got a new 20 inch oregon bar setup on.

Next is an 031 or 032 basketcase i want to get running hopefully out of the 3 i can get 2 runners.

And my 036 pro that just got all cleaned up for the first time since i inherited it. Got a new 20 inch oregon bar setup on.

Next is an 031 or 032 basketcase i want to get running hopefully out of the 3 i can get 2 runners.

Sierra_rider

Piss revver

and what is the difference between the two covers? 500i

The stock cover is narrow and fills up with chips during larger cuts with longer bars. My main complaint is that it also doesn't extend down to the bottom edge of the case...chips/saw dust don't get deflected away from the saw very well. It's not so bad if just bucking, but it's really messy/annoying when falling and using it in the more horizontal position. The WCS is wider and deeper...I don't know why the wrap-handle version of the 500 doesn't come with a larger cover like the older Stihls did.

170 finished. Fuel line solved the no rev up, then had to swap the needle due to drowning at idle. Seems ready to roll now. Thought the neighbors might object to a log test this time of night. Lol guess that has to wait til tomorrow.

View attachment VID_20221018_214101393.mp4

View attachment VID_20221018_214101393.mp4

lawrence

ArboristSite Lurker

I’ve got a good couple 288 it too heavy for me any idea what it’s worth running excellentA very low time Husqvarna 50 that a friend acquired. New fuel line, carb kit and a muffler from a 55 gets it running. Did some test cuts and it runs absolutely flawless. It's hard not to like this series of saw, very easy to work on and really reliable.

View attachment 1021502

link

Gone fishing

You got a couple of OEM 288 thats not templed with thats worth quite some coins.I’ve got a good couple 288 it too heavy for me any idea what it’s worth running excellent

No doubt will pay your gas bill...

If someone has put their screwdriver in it, or some Dremel tool... sorry - not so much.