wavefreak

Addicted to ArboristSite

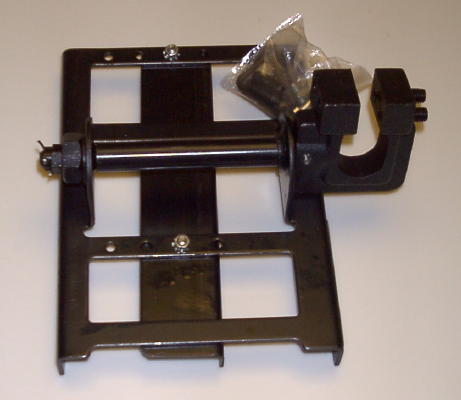

So, just finished my first little milling experiment yesterday. Don't laugh too hard, but I used one of these: http://www.woodcraft.com/product.aspx?ProductID=03P53&FamilyID=3037

and a Solo 650 with a 20" bar. (The plan is to convince my wife that a dork like me really CAN make a tree into a board, then after my son gets married in June get an Alaskan and a real chain saw).

Now that you are done snorting your coffee, you can laugh a little more. Sorry. No pics, but I got into what I was doing and didn't stop till I was done. There was a large maple on my property that was triple stemmed (is that what you call it?) and had split down the seams to about a foot above the ground. So last year I had it felled. The tree guy dropped it and I put a sign up "free fire wood". Everything disappeared except the monstrosity of the main trunk. So this ugly, 10 foot long, three fanged monster sat in my yard all fall and winter.

Why oh why would I pick something like this as my first milling, using a puny saw and what amounts to a jig?

Well, spending $1000 for tools just before the wedding was just not going to fly and I figure just about every problem possible could arise while doing this so WTF.

The flag pole stub in one side was the answer to the possibility of metal. Then there was the question of how to cut it up. I must have got lucky because I plunged about 8 holes along the seams and drove wedges in. It split apart rather nicely into 3 18" "logs". It was rotted in a few spots but was 90% sound. So me and my helper used 4x4s as levers and stuff and blocked them up off the ground. (Simple machines are fascinating, but I need to get better log handling tools.)

Using the little old Haddon I cut up the first log yesterday and ended up with four usable 2.5"x11.5"x8' maple boards, stacked and drying. Cool. They will eventually be surface planed down to 2", ripped into 1/8" strips and applied to the wall of the sun room I'm building.

So I am no longer a milling virgin.

As for the Haddon? It worked surprisingly well considering that it is nothing more than a jig to clamp on your bar. The cant I got was not quite square, but close enough. With more care that could probably be better. The cut was fairly smooth. But I think this could only be useful in the long run for something quick and small that doesn't require huge precision. But setup is really fast. Basically nail a guide board to the log.

But I think I'll be doing some more of this milling stuff. Seems a little more primal than sitting in front of a computer all day at my job. And primal can be good.

and a Solo 650 with a 20" bar. (The plan is to convince my wife that a dork like me really CAN make a tree into a board, then after my son gets married in June get an Alaskan and a real chain saw).

Now that you are done snorting your coffee, you can laugh a little more. Sorry. No pics, but I got into what I was doing and didn't stop till I was done. There was a large maple on my property that was triple stemmed (is that what you call it?) and had split down the seams to about a foot above the ground. So last year I had it felled. The tree guy dropped it and I put a sign up "free fire wood". Everything disappeared except the monstrosity of the main trunk. So this ugly, 10 foot long, three fanged monster sat in my yard all fall and winter.

Why oh why would I pick something like this as my first milling, using a puny saw and what amounts to a jig?

Well, spending $1000 for tools just before the wedding was just not going to fly and I figure just about every problem possible could arise while doing this so WTF.

The flag pole stub in one side was the answer to the possibility of metal. Then there was the question of how to cut it up. I must have got lucky because I plunged about 8 holes along the seams and drove wedges in. It split apart rather nicely into 3 18" "logs". It was rotted in a few spots but was 90% sound. So me and my helper used 4x4s as levers and stuff and blocked them up off the ground. (Simple machines are fascinating, but I need to get better log handling tools.)

Using the little old Haddon I cut up the first log yesterday and ended up with four usable 2.5"x11.5"x8' maple boards, stacked and drying. Cool. They will eventually be surface planed down to 2", ripped into 1/8" strips and applied to the wall of the sun room I'm building.

So I am no longer a milling virgin.

As for the Haddon? It worked surprisingly well considering that it is nothing more than a jig to clamp on your bar. The cant I got was not quite square, but close enough. With more care that could probably be better. The cut was fairly smooth. But I think this could only be useful in the long run for something quick and small that doesn't require huge precision. But setup is really fast. Basically nail a guide board to the log.

But I think I'll be doing some more of this milling stuff. Seems a little more primal than sitting in front of a computer all day at my job. And primal can be good.