mainewoods

Addicted to ArboristSite

Which raises a lot of questions - such as what makes them crack? The heat generated from the cutting causing the metal to become fatigued, or the port job causing added strain on the piston, for example ?

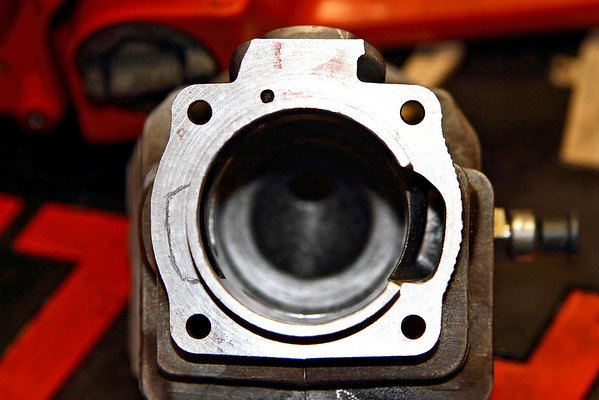

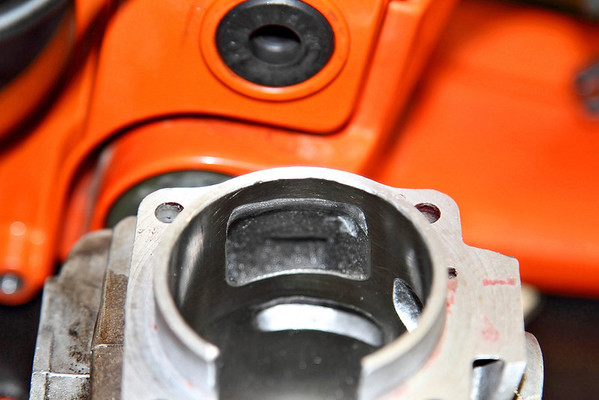

I went back in to open up the lower transfer ducts to the case. This idea came from Stihlbro. With this modification, windows would not be needed in the piston.......

Doesn't that just makes it an open port top end again and defeat the purpose of the whole exercise?

They ran pretty dang good didnt they.

They ran pretty dang good didnt they. Enter your email address to join: