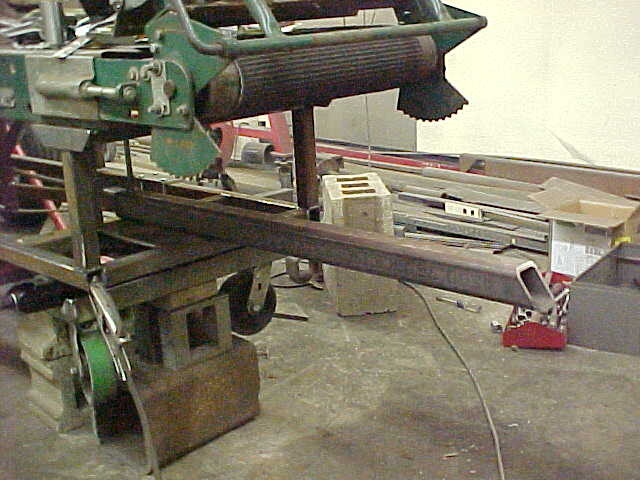

Sticking out the back side so I'll cut it off in the chop saw. and grind it all flush.

I then drilled and tapped it for a grease zerk while it was easy to do.

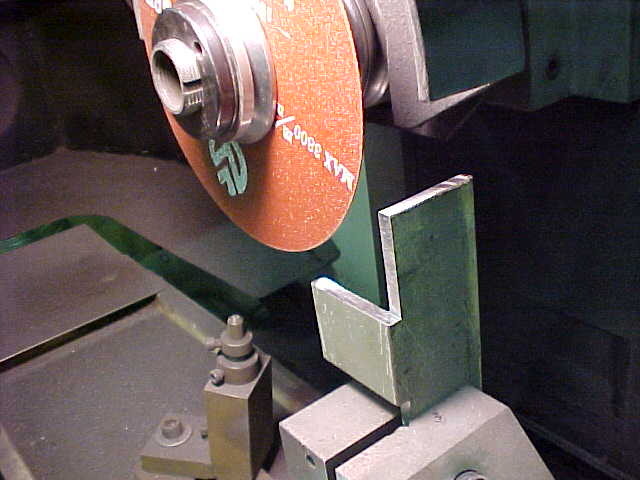

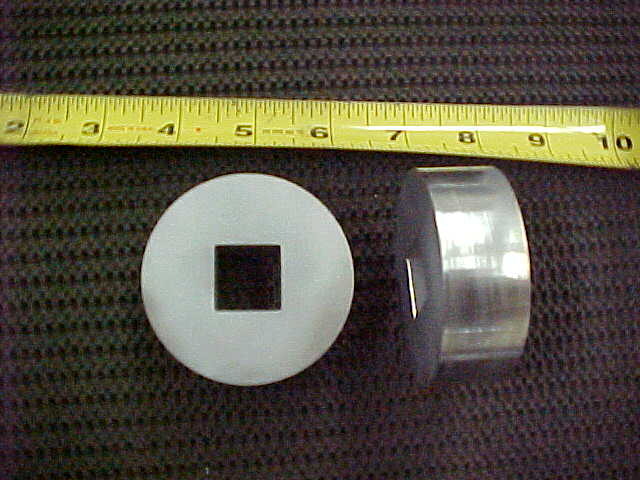

Cut the flat to 4 1/2 inches and rounded the one corner. I then got some bar stock and turned it to just fit the bushing. Test fit it here and slips on real smooth.

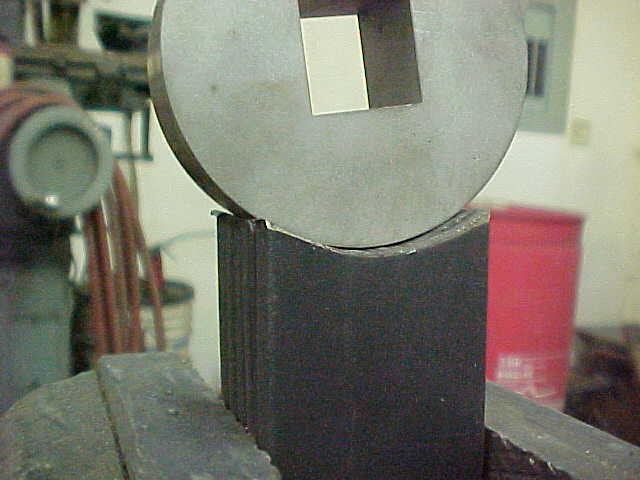

I then turned the shaft down to slip into the pipe. This way it'll self align when welding.

I angled both sides as I have to grind away everything above the shaft so I can remove it if need be.

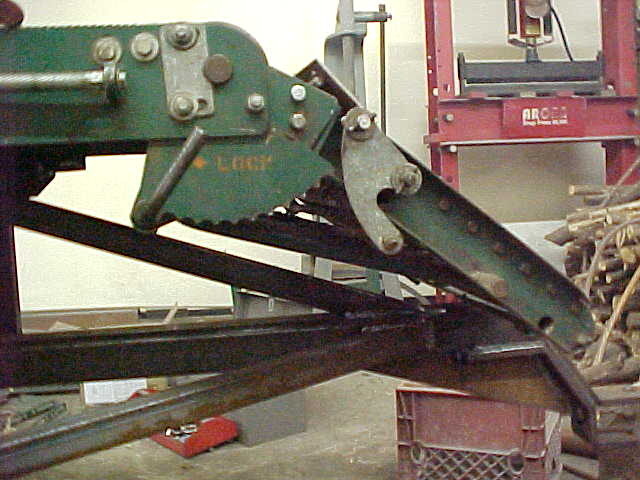

Welded it up with the MIG then I realized I should have just used the TIG as it would have been better. I'll have to smooth this out now.

Shaft all smoothed out and blended so it slips right in now.

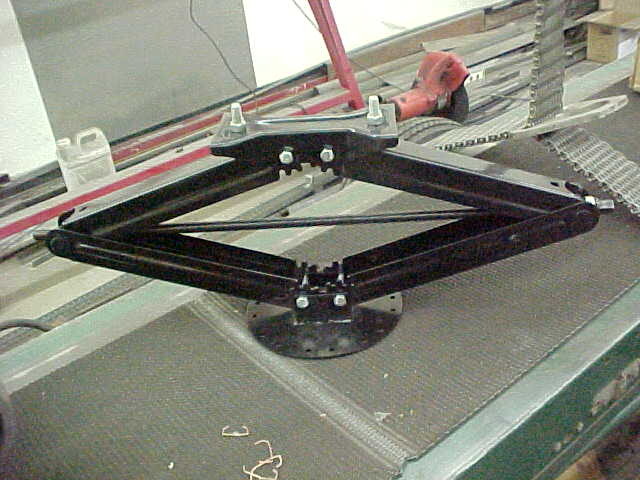

Put the shaft in and made sure it wasn't binding, then I welded the 1 x 3 block in place.

For the crank handle I want to be able to reverse it quickly so it's out of harms way. I cut off some round stock and gouged a slot in it with the chop saw in inset the original handle.

That is fantastic work.

That is fantastic work.