Okay, people seem to like build threads and I got a lot of favorable comments from the splitter so I'm going to do one on this conveyor. WARNING, this will be a step by step with lots of pics and descriptions so some my not like the detail. I always like stuff like this because I can pick up tricks and ideas for future projects. Not saying the way I do things is the best way, It's just the way I did it and Lord knows I make some mistakes along the way.

With the disclaimer out of the way, here's the plan. Always try to come up with something to make the wood gathering/processing easier. I take the approach of using the money saved to make the "system" easier. This also lets me be able to do wood heat longer as age creeps up on me.

here's the plan. Always try to come up with something to make the wood gathering/processing easier. I take the approach of using the money saved to make the "system" easier. This also lets me be able to do wood heat longer as age creeps up on me.

Been watching sale adds and such for a conveyor. My plan was to get a conveyor with options. I want to be able to use it as not only a conveyor but also a level, moving table that is totally adjustable. I have some ideas I have not seen on current offerings so some of it may be a little involved or may not work at all. All part of the fun huh? Here we go.

Got this conveyor off craigslist and it was listed by the manager of a closing Kmart store. It's 20 foot long and has a 2 ft wide with a 18 inch wide belt.

Just home here and backing it in to the shop. Luckily they loaded it with their forklift and helped getting it down to the floor. WE took rollers along to roll out then he again lifted it onto the trailer. Sure made it easy and glad they were so helpful.

They were using it to feed their storage loft and I bet many a box went up there. It has a 3/4 horse single phase motor with gear reduction.

A great feature it has is forward and reverse. I'll be using this flat a lot to load and unload but want to see how it will do loading into a trailer. No paddles or hooks will limit the steepness it can go but the belt is pretty rough and "grippy" so we'll see.

It has switches at top and bottom which is great as well. Outside out of reach of an outlet I'll have to take a generator along but it won't be a problem for me. Being able to switch on and off and reverse directions more than makes up for it.

My idea is to make a straight substructure so I can have a slide rollers to raise and lower it like a hay elevator. First step is to take off the feet that are on it.m It's all bolted on so it will be easy.

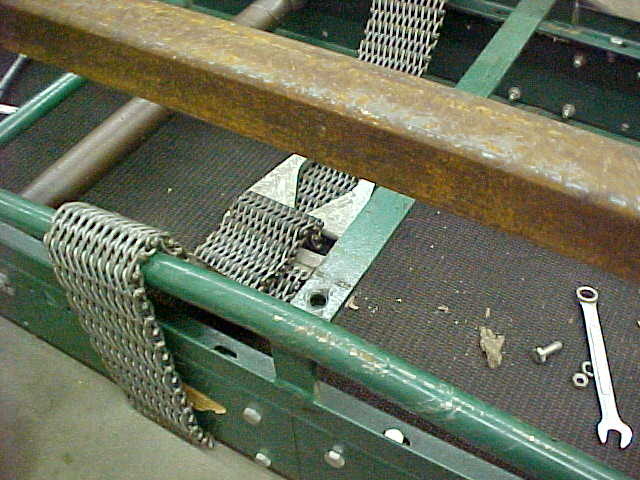

Took the cover off and got a surprise. Twine , plastic and tape was wrapped around the shaft. Then I notice something else. See how the chain is straight?

Either someone at the factory or whoever assembled this put the gear on backward. Notice the set screw can't even be tightened as it's on 2/3 on the shaft.It was loose and the only thing from keeping it on was the binding of the chain.

I think they did it because you have to have a long allen wrench to get in there if you put it on right. Notice all the stuff that was wrapped up in it on the floor.

With the disclaimer out of the way,

Been watching sale adds and such for a conveyor. My plan was to get a conveyor with options. I want to be able to use it as not only a conveyor but also a level, moving table that is totally adjustable. I have some ideas I have not seen on current offerings so some of it may be a little involved or may not work at all. All part of the fun huh? Here we go.

Got this conveyor off craigslist and it was listed by the manager of a closing Kmart store. It's 20 foot long and has a 2 ft wide with a 18 inch wide belt.

Just home here and backing it in to the shop. Luckily they loaded it with their forklift and helped getting it down to the floor. WE took rollers along to roll out then he again lifted it onto the trailer. Sure made it easy and glad they were so helpful.

They were using it to feed their storage loft and I bet many a box went up there. It has a 3/4 horse single phase motor with gear reduction.

A great feature it has is forward and reverse. I'll be using this flat a lot to load and unload but want to see how it will do loading into a trailer. No paddles or hooks will limit the steepness it can go but the belt is pretty rough and "grippy" so we'll see.

It has switches at top and bottom which is great as well. Outside out of reach of an outlet I'll have to take a generator along but it won't be a problem for me. Being able to switch on and off and reverse directions more than makes up for it.

My idea is to make a straight substructure so I can have a slide rollers to raise and lower it like a hay elevator. First step is to take off the feet that are on it.m It's all bolted on so it will be easy.

Took the cover off and got a surprise. Twine , plastic and tape was wrapped around the shaft. Then I notice something else. See how the chain is straight?

Either someone at the factory or whoever assembled this put the gear on backward. Notice the set screw can't even be tightened as it's on 2/3 on the shaft.It was loose and the only thing from keeping it on was the binding of the chain.

I think they did it because you have to have a long allen wrench to get in there if you put it on right. Notice all the stuff that was wrapped up in it on the floor.