Curlycherry1

Addicted to ArboristSite

If you go with 2x8 walls, I gotta ask what are you going to do for windows and doors. I've never seen frames for them bigger than 2x6. Custom ordering them could be outrageous.

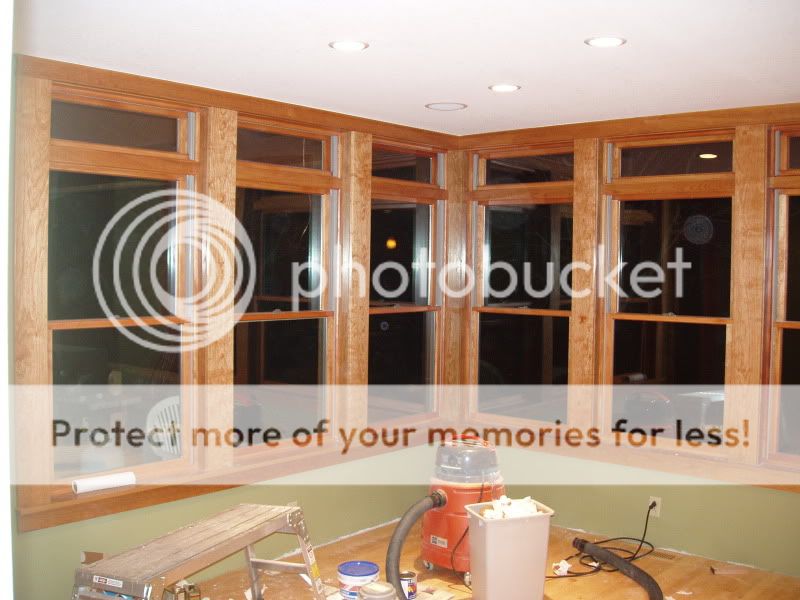

Building custom extension jambs on site is an easy task that anyone with a cheapo table saw can do. Any trim carpenter can do it and it is simple. I made all the extension jambs in my house because they are made out of either cherry or maple and cherry is not an extension jamb option from the company my windows came from.

Photo of solid cherry extension jambs and window trim:

Photo of my SIPs roof panels being put in place:

One thing about SIPs is that you need to have ridge supports and so there are often beams that can be left exposed inside of the structure. Here is what the inside roof of my screeened in porch looks like and as you can see, it adds some features rather than plain old drywall. I added beadboard to the bottom of the SIPs panels. The beams are treated with Sikkens(tm) outdoor stain and it makes the beams look just like walnut beams.