2broke2ride

Addicted to ArboristSite

- Joined

- Jul 20, 2014

- Messages

- 1,862

- Reaction score

- 2,491

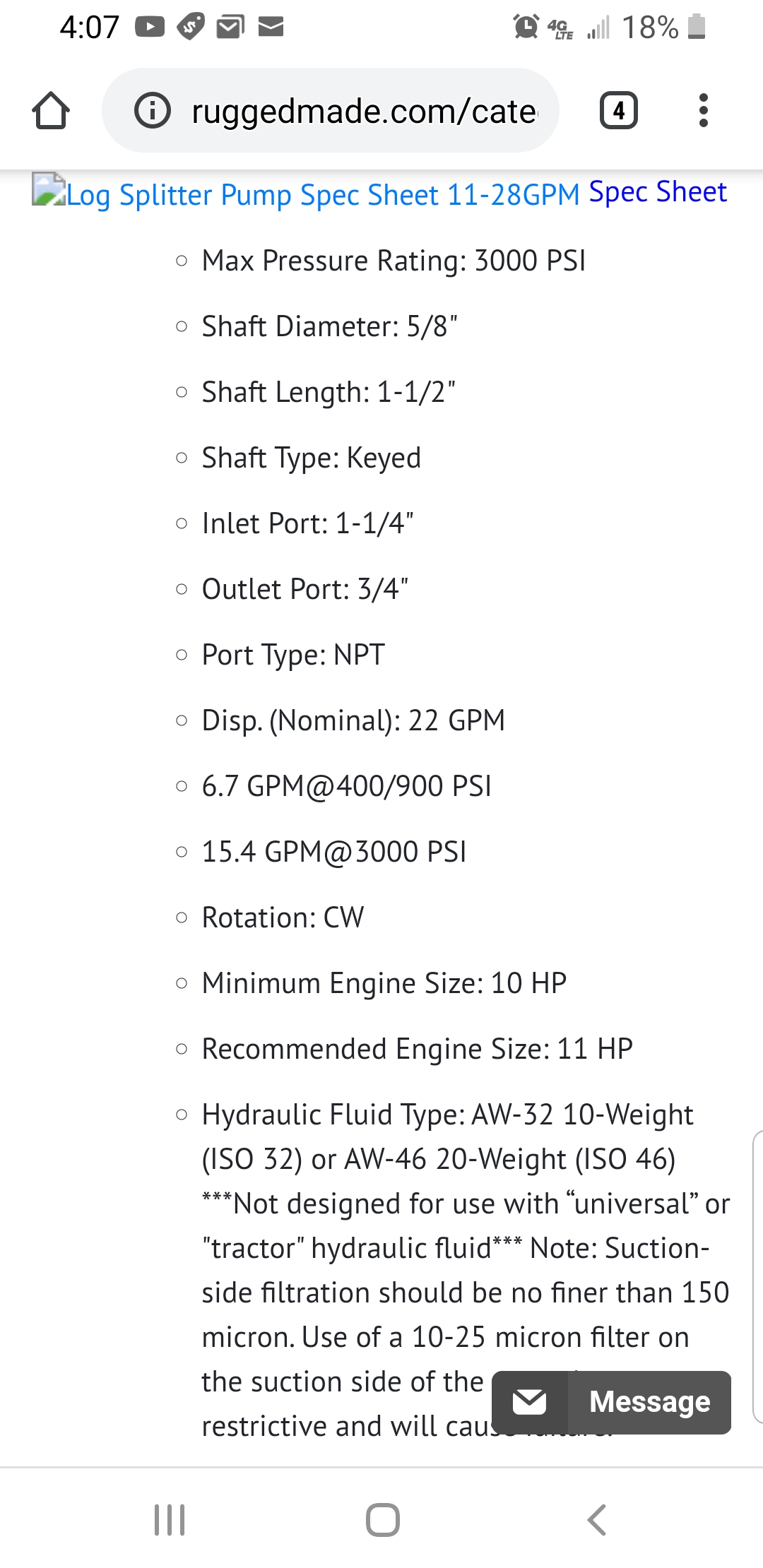

A couple of months ago I asked here about upgrading my speeco 22 ton splitter to get a faster cycle time. I ended up going with a 16gpm pump and an 8hp engine. It turned out very well and I am happy with it. However, I have been bitten by the bug to build a splitter the way I want it. The idea behind this is speed. So I am going to run a 22gpm pump. I am starting with this beast, I traded some work for it so no out of pocket cost. I have a friend who runs a hydraulic shop so lines will be no problem and he is going to rework the piston to have 3/4 inch ports and machine a slug to shorten the stroke to around 20inches. I only split 18inch wood so anything more is a waste. I have a couple engines to choose from. I have a 10hp tecumseh and an 11hp Briggs and Stratton. The only thing I'm really lacking is a tank. My research has suggested I want about 20 gallon capacity. Everything I'm finding premade is almost $300, I would rather spend that money on an auto cycle valve when the time comes. Anyone have ideas of something that could be easily repurposed?

Anyways, pics or it didnt happen right?

Sent from my SM-G950U using Tapatalk

Anyways, pics or it didnt happen right?

Sent from my SM-G950U using Tapatalk